GLOBAL Optics

Optical high-resolution measurements of miniature size and form features on challenging surfaces

Need to measure microgeometries on sensitive surfaces?

Use high-resolution optical sensors for parts that cannot be touched.

Would you like to know more?

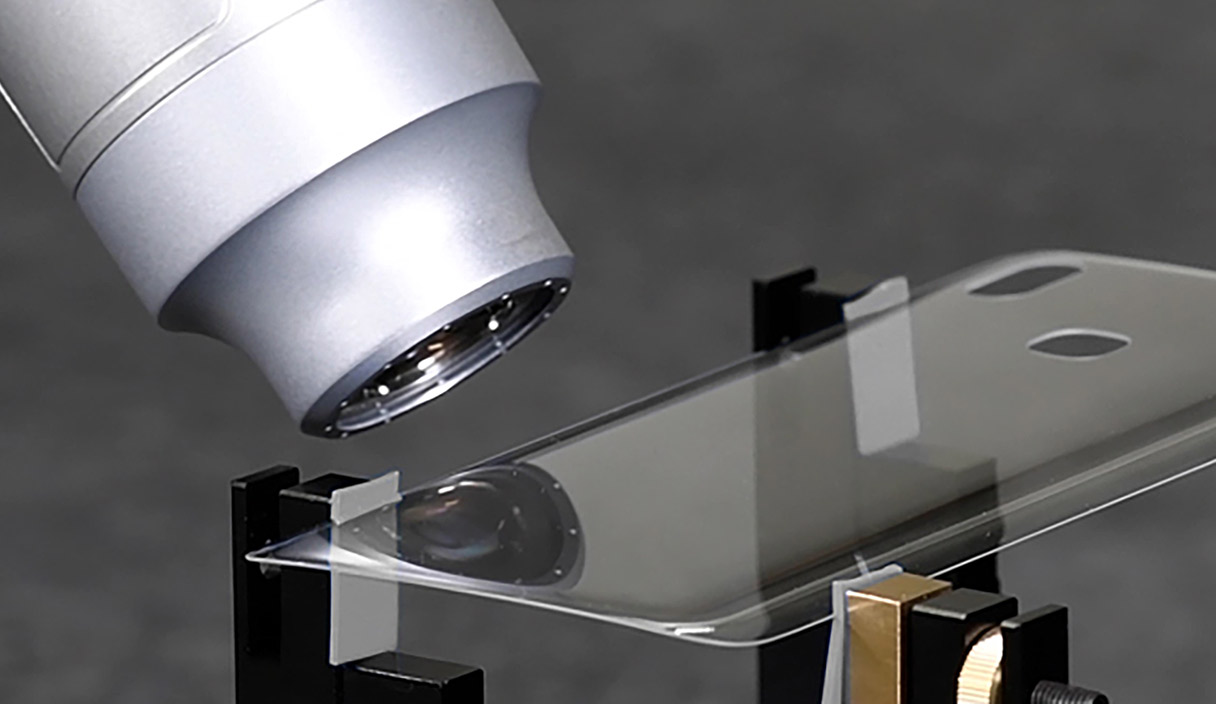

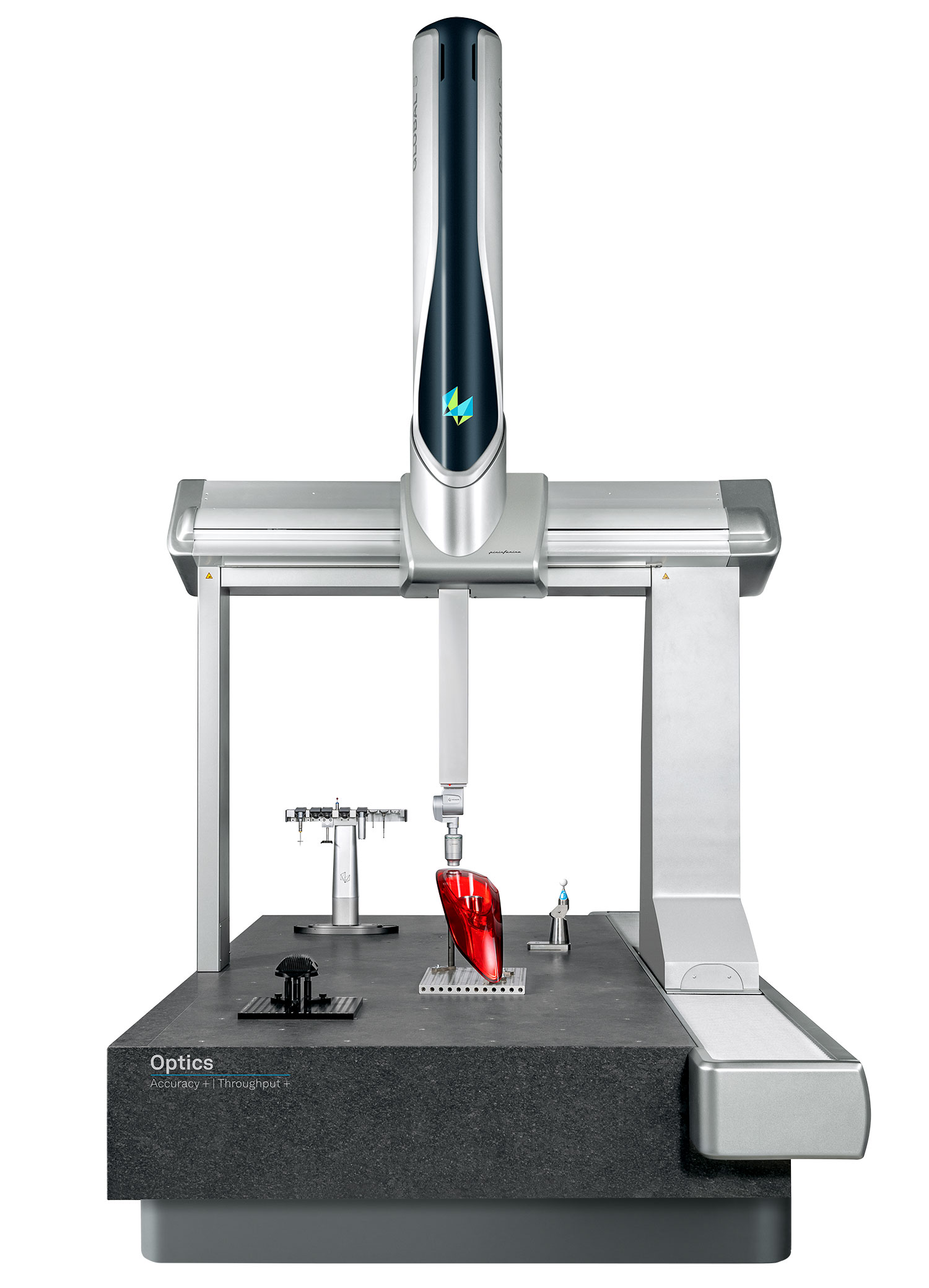

Equipped with a chromatic white light sensor as standard, GLOBAL Optics is ideal for non-contact measurement of the geometric size and form characteristics of sensitive workpieces that cannot be touched and those with particularly challenging surfaces.

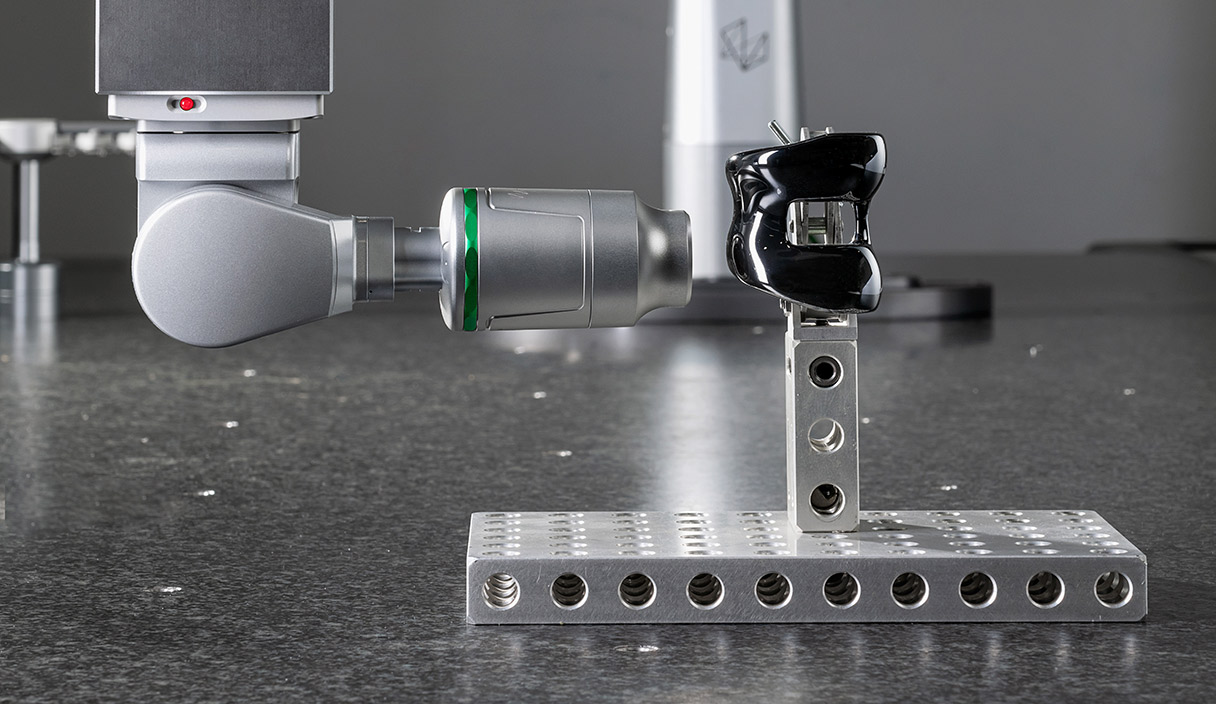

An indexing probe head provides excellent access to part features from almost any angle and direction, allowing optimal alignment of the chromatic white light sensor to the measured surface. Furthermore, in combination with an automatic sensor changer rack, and thanks to Hexagon’s opto-mechanical sensor interface, different sensors can be easily exchanged on the indexing probe head, maximising the CMM’s multisensor flexibility.

Typical applications

Application challenges

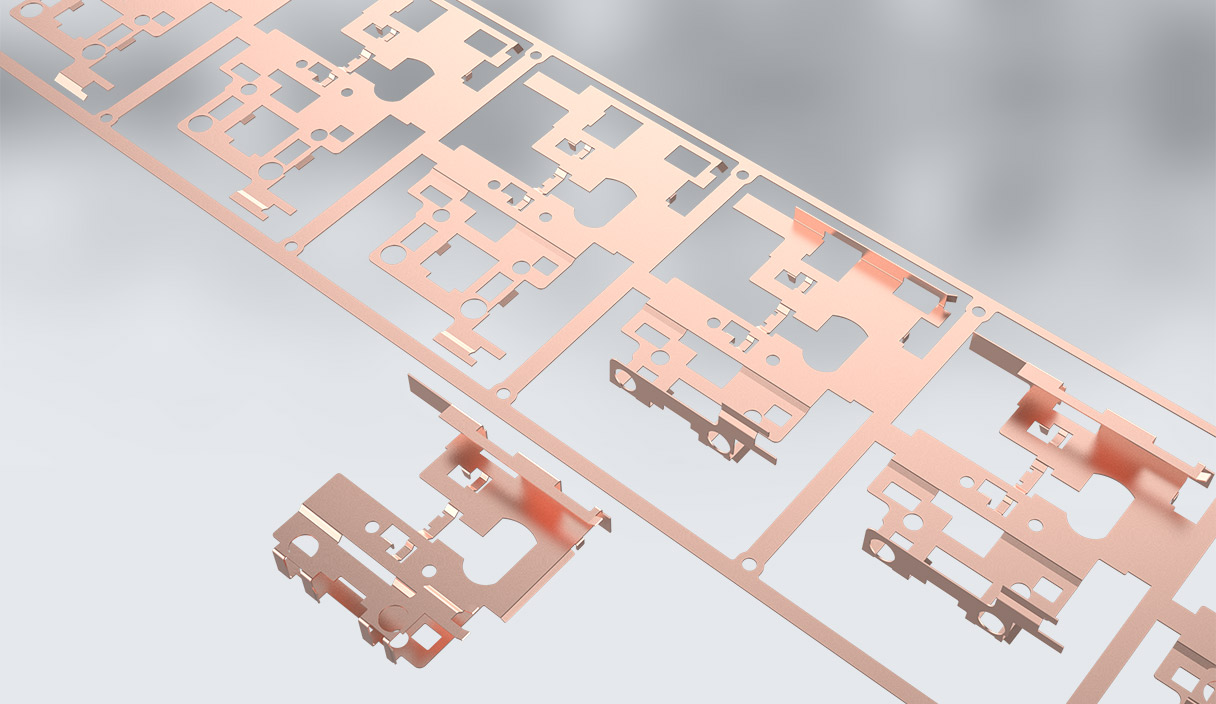

Non-contact size and form measurements on varied part surfaces

- Soft and sensitive parts that cannot be touched

- Very small geometries (microgeometries)

- Varied materials and surface finishes: matte, transparent, reflective, microstructured, coated

GLOBAL Optics benefits

- Optical high-resolution measurement for capturing the smallest geometric structures

- Single‑point distance measurement and scanning of freeform surfaces

- Surface-independent measurements

- Thickness measurements on transparent materials

How the GLOBAL Optics builds

Options tailored to individual application needs

Manufacturers can further tailor the capabilities of each base model GLOBAL Optics machine with options to meet their application needs best. A range of options can be selected during initial CMM configuration, and most can be set up later as upgrades to the in‑service machine.

The Global Optics model can be equipped with additional sensors to make it suitable for a larger field of applications:

HP-C camera sensor

Optical measurements of small features and sensitive or easily deformed components

HP-S-X1 scanning probe

Compact tactile probe for highly accurate scanning applications

The XT (extended temperature) option allows the GLOBAL Optics model to be used in less controlled temperature environments, enabling accurate and reliable measurements near the production line without needing a costly climate room.

Accuracy+ reduces the CMM’s volumetric measurement error to the next level of accuracy and increases repeatability to address tighter part tolerances. The need for such capability is a growing trend in many industries.

At the same time, throughput is key to avoiding delays and ensuring parts are shipped on time. High measurement throughput is particularly important for near-line and 100% part inspection.

Throughput+ boosts measurement productivity of the GLOBAL Optics by significantly increasing the machine’s maximum measurement speed without compromising accuracy or precision.

Tabletop rotary tables for the GLOBAL Optics model enhance access to workpieces from any angle, so even highly complex parts can be measured quickly, with fewer probe changes, increasing throughput.

The GLOBAL Optics model can be equipped with various other options to get the most out of the machine for every application:

PULSE wireless real-time environmental monitoring

This system helps ensure measurement data integrity by notifying users of temperature, humidity, vibration, air pressure and luminosity changes that might affect measurement results.

Messaging lights

Messaging lights give operators the ability to monitor the machine’s status even from a distance, to optimise time and resource management.

Eco Mode+

The option reduces compressed air consumption by up to 90% when the machine is idle and saves up to 25% of compressed air costs under normal machine operating conditions.

Features and benefits

GLOBAL CMMs are built on advanced design principles to inspire certainty and confidence. They combine quality components and state-of-the-art technologies for long-term stability, reduced measurement uncertainty, adaptability to harsh measuring environments, fast measuring point capture and an advanced user experience. These metrology solutions will provide manufacturers with maximum value over the entire lifecycle.

Sturdy mechanical design

The solid granite base with integrated dovetail guide guarantees long‑term system stability and consistent accuracy over the entire measurement volume.

Bridge with triangular crossbeam

Featuring an improved stiffness-to-mass ratio relative to square or rectangular traverses, this design allows for the highest dynamics and high‑speed measurements.

Preloaded air bearings on all axes

Contactless, low-friction and low-wear axis motion ensures fast and repeatable positioning at all speeds and accelerations, resulting in low measuring uncertainties.

Low-maintenance belt drive system

Flat and V-ribbed belts ensure smooth and low-vibration axis motion.

Temperature compensation

Real‑time compensation of thermally caused measurement deviations through temperature sensing at the scales and on the workpiece ensures reliable measurement results.

Extended temperature operating range (option)

Measure your components with more resistance to environmental influences. An extended temperature operating range (15 - 30°C) allows the CMM to operate closer to the production line without needing a costly climate room.

Real-time environmental monitoring (option)

PULSE enables the user to monitor and log any environmental conditions surrounding the CMM and receive real‑time machine information.

Eco Mode

Eco Mode supports sustainability and productivity goals by automatically powering down the CMM when idle, which improves energy efficiency while keeping the machine ready to go.

Messaging lights (option)

Messaging lights give operators the ability to monitor the machine’s status even from a distance, to optimise time and resource management.

High-speed and safety

Continuous monitoring of a defined safety area around the CMM allows worry-free high-speed measurement in CNC mode. The machine will slow down automatically when the user or an object encroaches upon the protected area.

Multisensor versatility

Using the widest range of tactile and optical sensors with Hexagon’s universal sensor interface, the CMM becomes a multisensor inspection device that can adapt to the most complex measuring tasks.

Future-ready concept

The future‑ready pre‑cabling enables easy adaptation of the CMMs to future measurement tasks without costly downtime. A range of adaptability options can be flexibly selected during initial CMM configuration or set up later as upgrades.

Customer Stories: GLOBAL CMM Solutions

Hexagon CMMs and PC-DMIS for an improved hip prosthesis manufacturing process | Dedienne Santé

Adaptable automated measurement using Hexagon GLOBAL S CMM & HP-OW optical sensor

Quality control of gearbox housings in an automated production cell

GLOBAL CMMs and PC-DMIS software for aerospace | Mecamesures, France

-

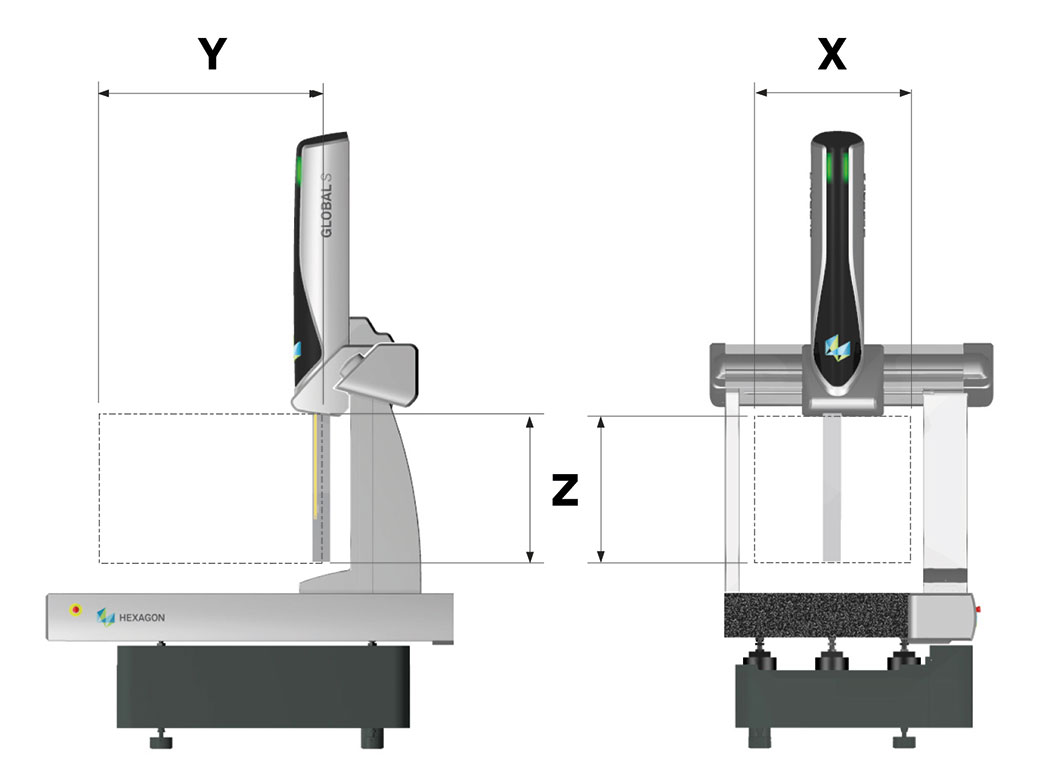

Measuring volume

Type X (Width) Y (Depth) Z (Height) 7.7.5 700 mm 700 mm 500 mm 7.10.7 700 mm 1000 mm 700 mm 9.12.8 900 mm 1200 mm; 800 mm 9.15.8 900 mm 1500 mm 800 mm 9.20.8 900 mm 2000 mm 800 mm 12.15.10 1200 mm 1500 mm 1000 mm 12.22.10 1200 mm 2200 mm 1000 mm 12.30.10 1200 mm 3000 mm 1000 mm 15.22.10 1500 mm 2200 mm 1000 mm 15.30.10 1500 mm 3000 mm 1000 mm 15.20.14 1500 mm 2000 mm 1400 mm 15.26.14 1500 mm 2600 mm 1400 mm 15.33.14 1500 mm 3300 mm 1400 mm 20.33.15 2000 mm 3300 mm 1500 mm 20.40.15 2000 mm 4000 mm 1500 mm

-

Downloads