Solutions for Load & Haul

Strategising your loading and haulage against other planning and operational constraints can measurably improve safety, lower costs and boost productivity. Hexagon is the only technology company that integrates standard fleet management features with machine guidance, equipment health and safety capabilities. Using a single fleet management platform, our hardware and software help safely optimise production and manage operators. Built-in insights deliver real-time situational awareness to mine controllers for efficient and transparent tracking, monitoring and reporting of machines and miners both above and below ground. Robust short-interval control processes can be applied to planning, production, maintenance and safety workflows, and data can be leveraged from in-field devices and control room data inputs, irrespective of communication network constraints.

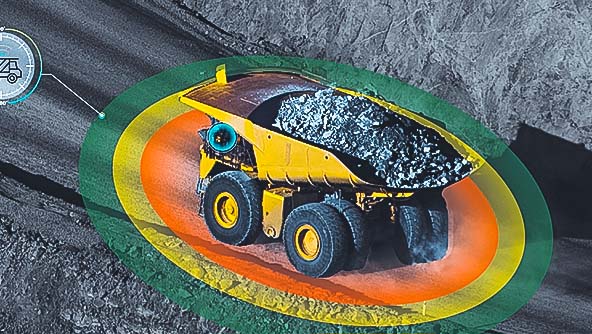

Hexagon’s powerful fleet management platform can be combined with our Collision Avoidance System (CAS) for both surface and underground operations, protecting operators, vehicles and assets via a peer-to-peer system that needs no infrastructure network to detect tagged objects.

Explore our solutions for Load & Haul below.

-

Product

ProductCut costs, not corners, with automated, sensor-driven data loggers that help extend equipment life and prevent costly machine failures.

-

×Human-Assisted autonomyElectromechanical steering system that provides a retrofit solution for tractors, sprayers and harvesters.

-

-

Product

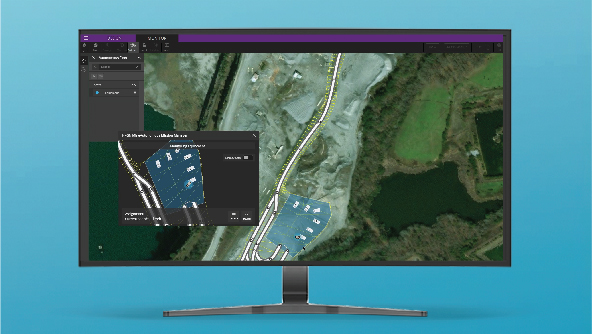

ProductOptimise the movement of autonomous and non-autonomous vehicles through one interface.

-

×Full autonomyHexagon Mission Manager is a next generation command-and-control system that empowers mines to take FMS optimisation one step further. It enables dispatchers to gain full control over vehicle operations with superior coordination of loading and unloading activities. Enhanced control means mines can protect the planet and the bottom line by targeting idling time and cutting down on fuel costs.

-

-

Product

ProductIncrease equipment lifespan, enhance drill operator performance and improve blasting outcomes with dynamic corrective action technology.

-

×High autonomyAlgorithms monitor all input signals and take dynamic, autonomous corrective actions to avoid hole failure.

-

-

Product

ProductProtect people, equipment and your bottom line with a world-class vehicle intervention system designed specifically for mining equipment.

-

×Conditional autonomyHardware that applies breaks in several unsafe scenarios when the operator does not.

-

-

Product

ProductSafeguard your people and assets with a machine-learning system that continuously, objectively monitors for operator inattention.

-

×Human-Assisted autonomySensors and algorithms analyze faces to detect fatigue and/or distraction.

-

-

Product

ProductHexagon Radio Remote Controller (RRC) is a robust remote-control solution designed for efficient and safe heavy equipment operation.

-

×Human-Assisted autonomyRadio Remote Control

-