Upgrades and retrofits

Revitalise your CMM to reignite your quality control capabilities and boost your productivity

Contact us

The dynamic nature of manufacturing means there is an increasing demand for manufacturers to meet a wider variety of measurement and reporting needs. This means having the most efficient toolset of inspection solutions installed and operational at all times is essential.

But the constant evolution in tasks and challenges often outpaces the capabilities of even the best-performing CMMs.

In the era of smart manufacturing, upgrading or retrofitting your CMM allows you to take advantage of the advancements in electronics, PC systems, measurement software, controllers, and sensors. There are extensive possibilities to upgrade your existing CMMs in a cost-effective way that extends their useful service life and revitalises and enhances their performance for greater productivity.

Whether you’re looking to upgrade your software, add new sensor technology, or implement a more comprehensive upgrade, our engineers can help you identify the best upgrade or retrofit options to optimise your inspections and ensure your equipment keeps pace with the latest standards.

Retrofit or upgrade – what’s the difference?

- A retrofit involves replacing the original CNC with a new controller

- An upgrade enhances existing components of the machine while keeping the original CNC

How you can benefit from a retrofit or upgrade

There are many benefits from retrofitting or upgrading an installed CMM, from enhanced accuracy and increased efficiency to cost savings and reduced downtime. Read our Top 10 reasons to retrofit blog to find out more.

What might an upgrade or retrofit involve?

Upgrades and retrofits aren’t available as predefined service packages. This is because the condition of each CMM subsystem must be carefully evaluated before we can propose the best options for that specific machine to meet your measurement needs.

-

Your benefits

-

Our services

Sensors

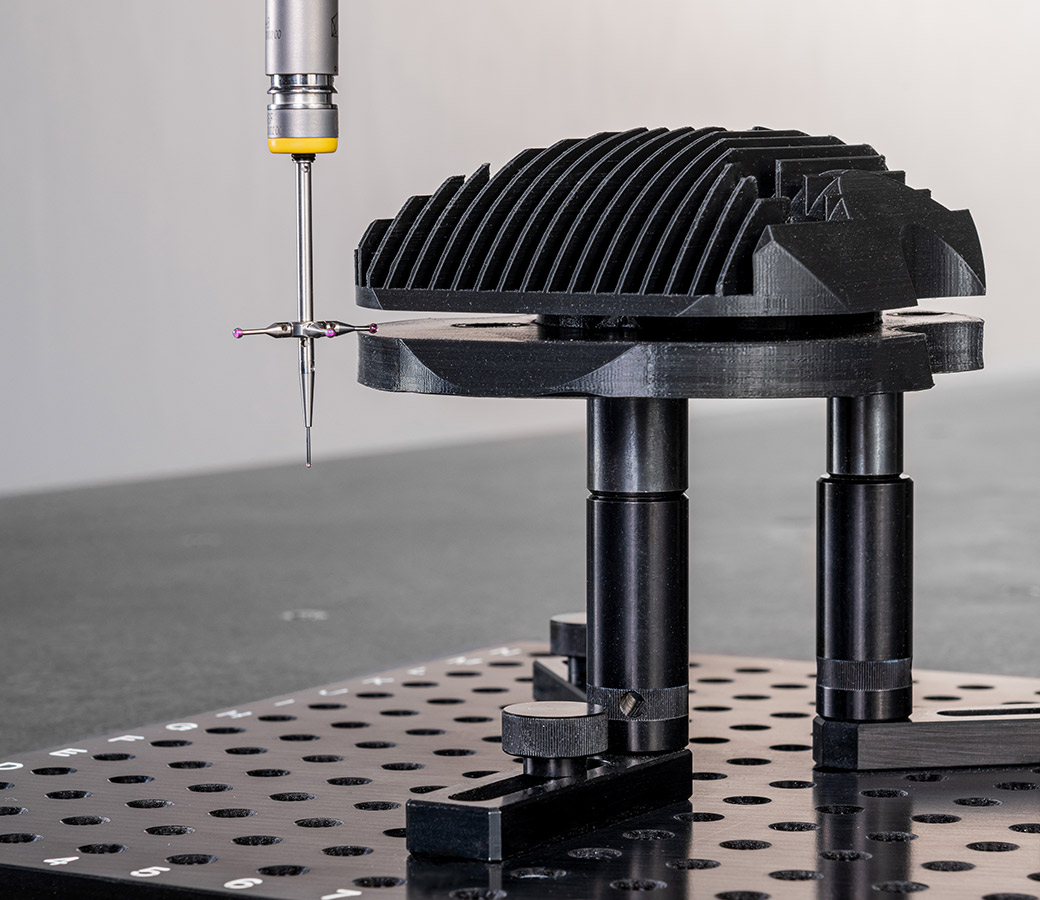

Tactile measurement is at the heart of the CMM inspection process, with modern touch probes offering many benefits over older technology.Non-contact sensors add flexibility to a metrology setup and are typically used to optimise measurement or to inspect objects that contact-based probes cannot.

Software

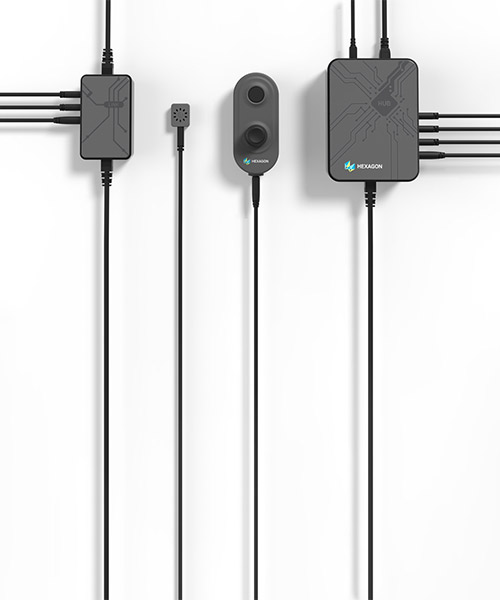

Augmentation systems

Advancements in key areas tangential to the inspection process offer significant opportunities to push productivity further.

Automation – Enhance CMM workflow with off-the-shelf automatic part loading

Achieve interruption-free measurement with Hexagon’s automated part-loading solutions that enable a CMM to maintain output overnight or when operators are unavailable.