FASTFORM Advanced

Body in White Formability Assessment, Springback Analysis and Blank Shape Development

Blank Development and Early Feasibility

A solution for sheet metal components to optimise the design and forming feasibility.

Ready to learn more?

Design engineering software solution for sheet metal components

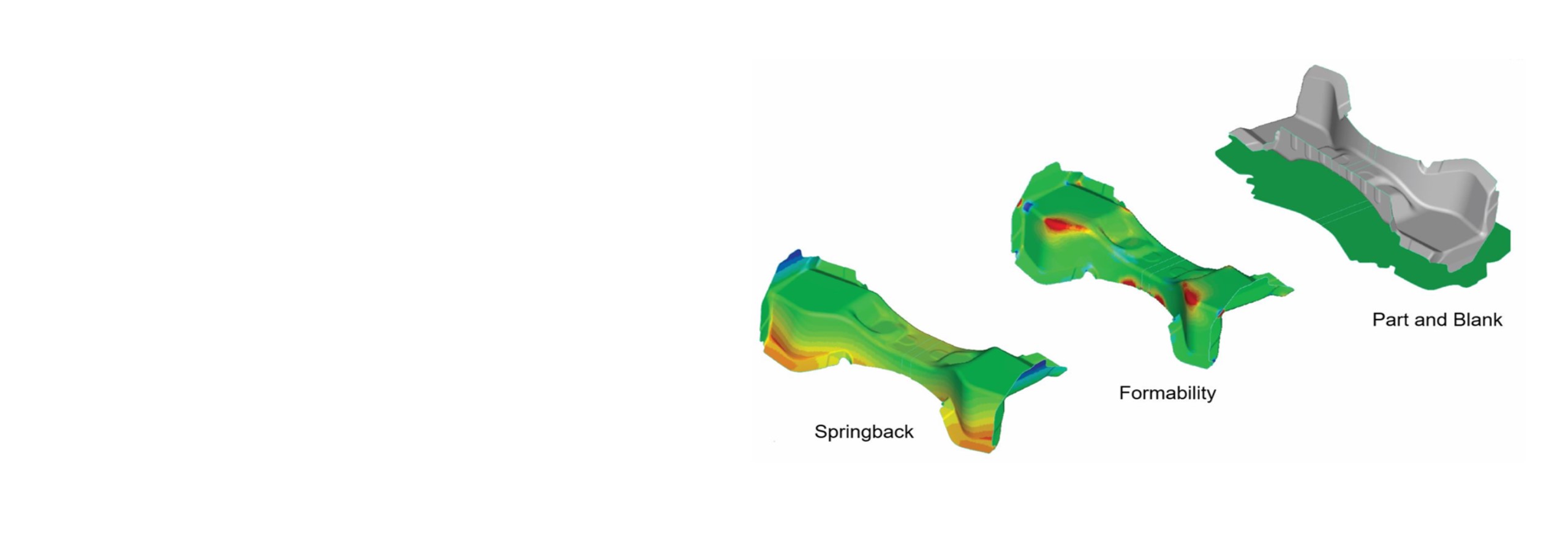

FASTFORM Advanced enables users to quickly and easily evaluate part and process feasibility as well as determine blank shape and spring back for sheet metal components.

It identifies formability problems (splits/wrinkles), enabling users to implement design changes earlier in the product life cycle, saving time and money. Before releasing data to tooling, engineers run FASTFORM Advanced to assess formability risks and optimise material usage. It considers component or tool geometry and accounts for material properties, friction, binder, addendum, blank holder force, pad pressure, draw-beads, and tailor-welded blanks.

Features in FASTFORM Advanced

Design engineering software solution for sheet metal components

FASTFORM Advanced enables users to quickly and easily evaluate part and process feasibility as well as determine blank shape and spring back for sheet metal components.

It identifies formability problems (splits/wrinkles), enabling users to implement design changes earlier in the product life cycle, saving time and money. Before releasing data to tooling, engineers run FASTFORM Advanced to assess formability risks and optimise material usage. It considers component or tool geometry and accounts for material properties, friction, binder, addendum, blank holder force, pad pressure, draw-beads, and tailor-welded blanks.

-

Case studies

-

Case studyCar seat manufacturer cuts costs and improves quality

-

Case studyKawasaki Heavy Industries

-

Case studyQuality Pattern Works Pvt Ltd.

-

-

Collateral