HxGN Virtual Manufacturing

Virtual manufacturing simulation software harnesses powerful simulations and innovation to drive sustainable and efficient manufacturing processes, enabling manufacturers to achieve ‘Shift to Zero’.

Virtual Manufacturing of the Future

Take your manufacturing to the next level of sustainability with virtual manufacturing solutions

Ready to get started?

Software Solutions for optimising processes and manufacturing efficiently

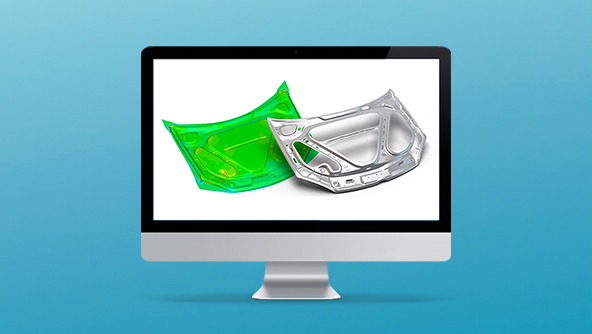

Create reliable and accurate virtual manufacturing realities with a wide range of simulation software, including metal forming, assembly & joining, and additive manufacturing, aiming at optimising manufacturing processes during design.

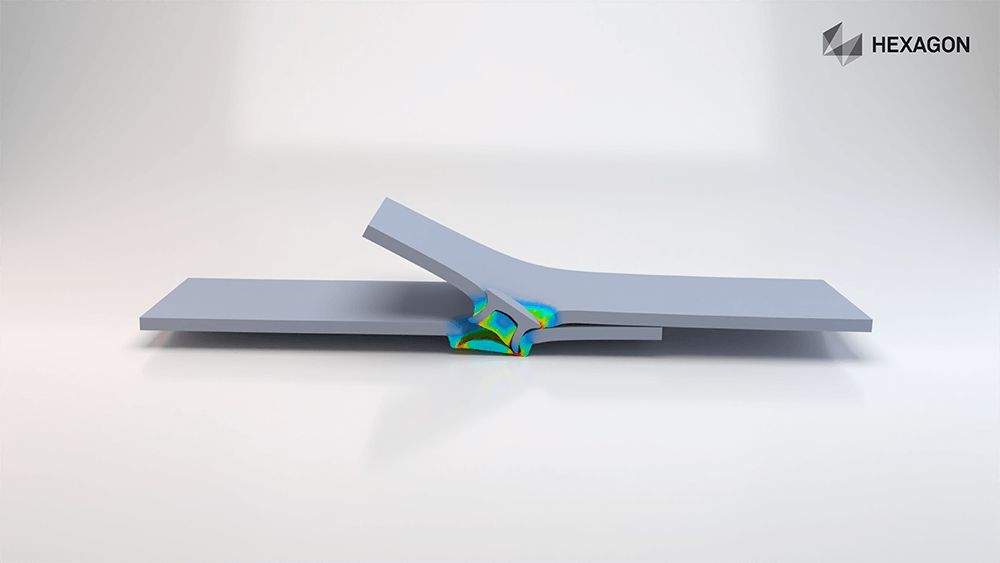

Perform quick feasibility studies of sheet metal parts during the design phase to enhance designs for manufacturability (DFM) quality. The forming solution streamlines the forming process by eliminating re-work and reducing engineering changes after part design release. It also provides fast and accurate estimations of blank shapes and springback for sheet metal components, improving the part’s overall efficiency.

Cost Engineering

Define target costs early in the design phase through a realistic stamping cost engineering analysis. Manufacturers and engineers can effectively derive should-cost scenarios, improve overall material utilisation, and reduce vehicle weight and tooling development time.

Process Planning / Technical Planning

Develop a detailed process plan for quoting & estimating from your 3D CAD (Computer Aided Design) design. Generate realistic images for each die operation. This scientific and data-driven approach empowers cost and design engineers to derive fast and accurate quoting and estimating processes and technical planning.

Virtual Process Validation

Perform quick virtual try-outs of stamping and assembly processes and identify issues before tooling kick-off to reduce costs and time-to-market while improving product quality. The 3D explicit incremental analysis provides a complete virtual die development and try-out for tool and die makers.

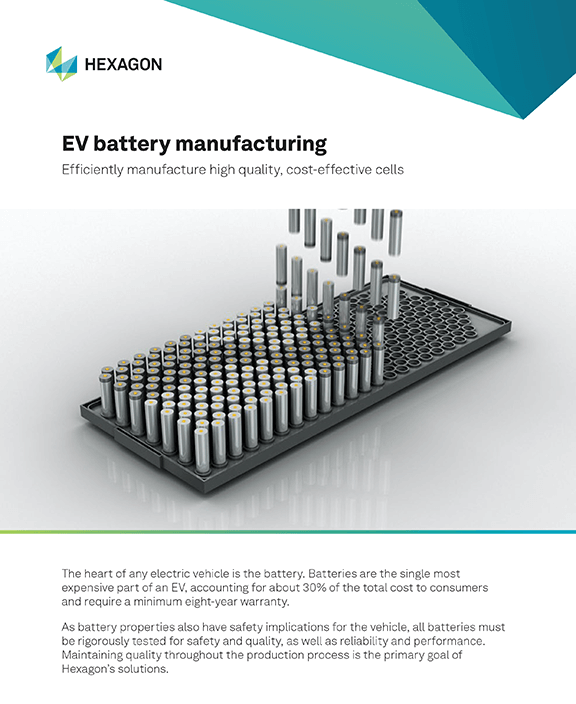

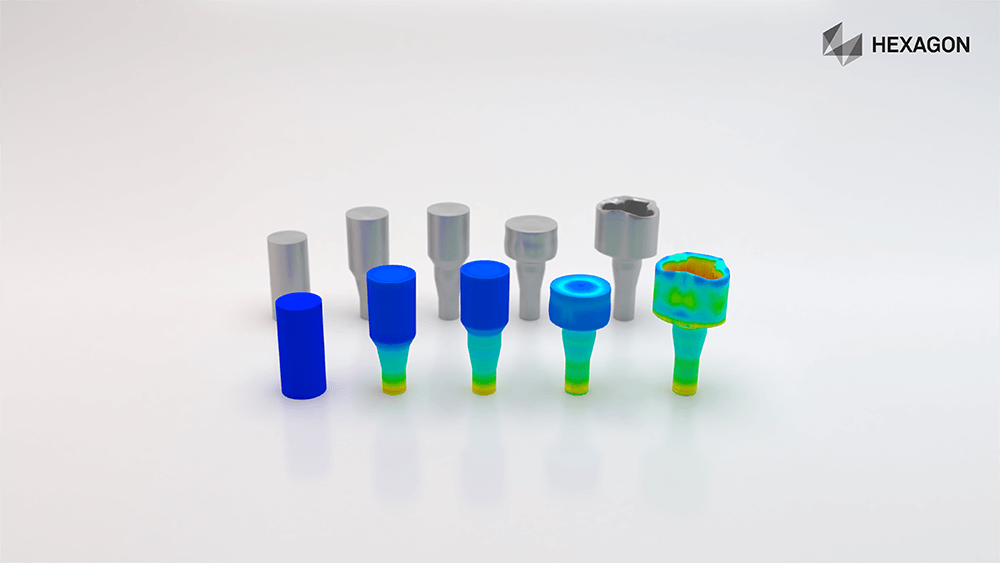

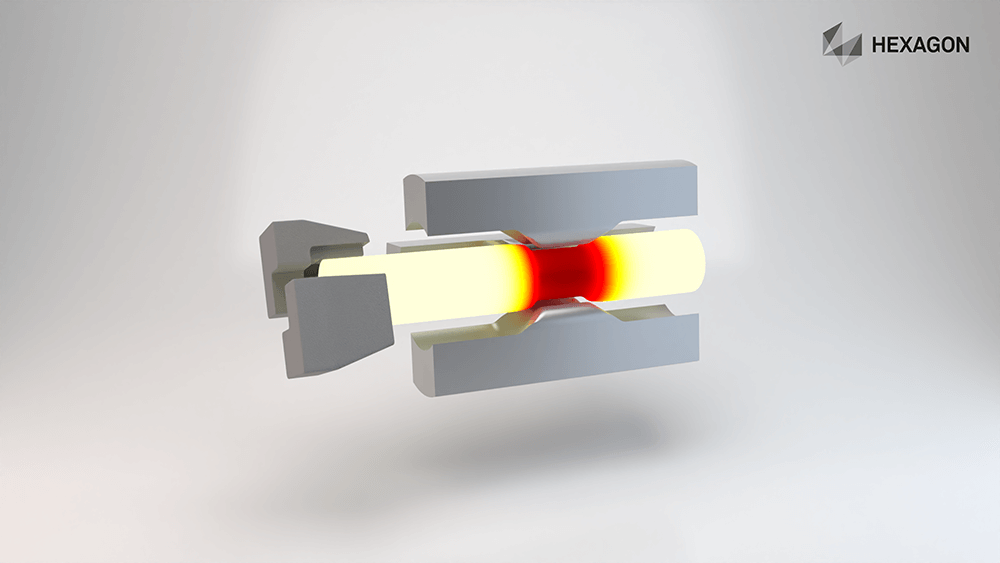

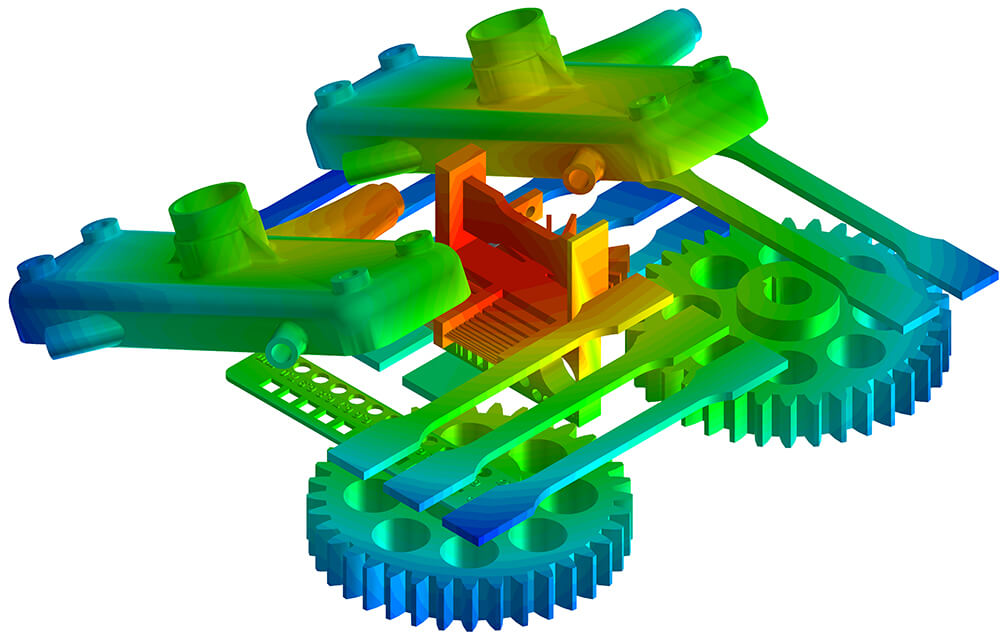

Be it forging, rolling, extrusion or other methods, bulk forming is an indispensable production technology that many products rely on. Given the influence of temperature, material flow and permanent deformation, our advanced simulation is necessary to effectively establish and control the process effectively.

Cold & Hot Forging

Enhance your cold and hot forging processes with our advanced simulation tools. Our software accurately models and simulates both techniques, enabling you to optimise manufacturing processes, predict defects, and improve tooling designs. Visualise material flow and temperature distribution for superior results.

Incremental Forming

Our advanced software offers precise modelling and simulation capabilities for incremental forming processes, enabling you to optimise your manufacturing operations. Visualise and analyse material flow, tooling interaction, and deformation throughout the incremental forming process. By virtually fine-tuning process parameters and evaluating tool designs, you can enhance efficiency, predict potential defects, and achieve superior quality in your formed components.

Heat Treatment

Transform your heat treatment processes with our powerful modelling and simulation capabilities, enabling you to optimise thermal processes and predict material behaviour. Visualise temperature distribution and residual stresses during heat treatment. With our solution, you can fine-tune process parameters, optimise cycle times, and ensure the desired material properties and microstructures are achieved.

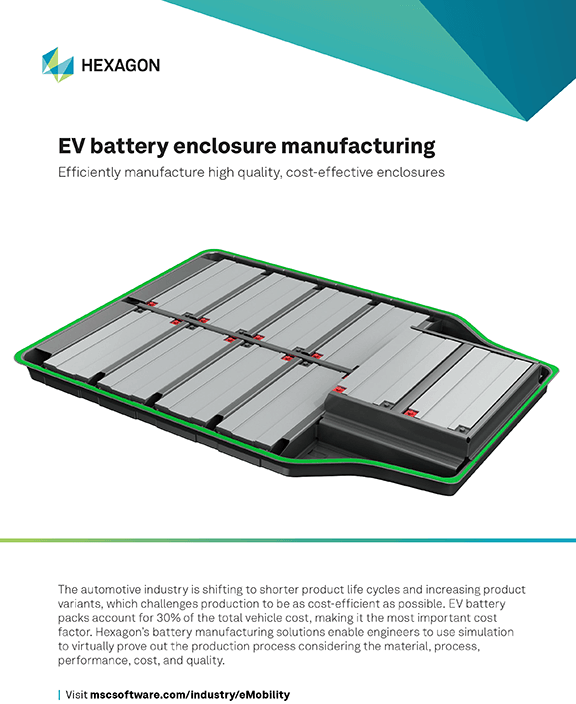

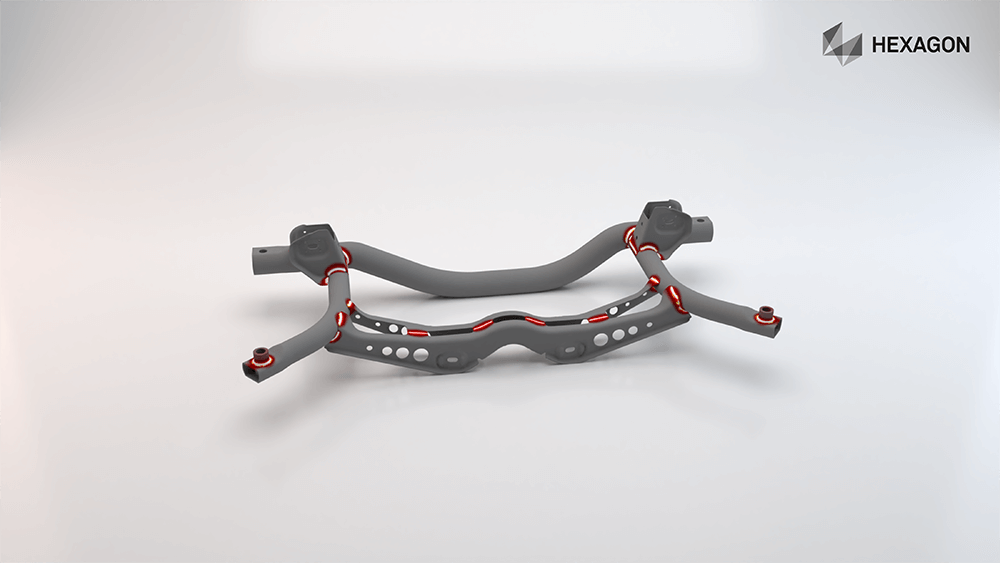

Joining parts is a fundamental aspect of manufacturing, and a reliable and stable process is key for achieving high-quality parts. Simulation plays a vital role in optimising this process, leading to improved quality, cost reduction, and the maintenance of a robust assembly process.

Arc Welding

Optimise your welding processes with our advanced welding simulation tool. Our software accurately replicates the melting and fusion of metal parts, allowing you to assess weld bead formation, residual stresses, and distortion. The solution facilitates refining welding parameters, identifying defects, and ensuring structural integrity before fabrication. Reduce the need for physical try-outs, save time and costs while maintaining quality.

Spot Welding

Experience the power of spot welding simulation with our advanced software. Replicate localised heating and pressure, evaluate weld quality, and optimise processes. Fine-tune parameters, assess defects, and enhance spot weld design. Drive efficiency and excellence in your manufacturing process with our trusted solutions.

Mechanical Joining

Our advanced software accurately models and simulates various mechanical joining techniques such as riveting, bolting, and clinching. By virtually replicating the joining process, our tool enables you to reduce efforts, predict joining characteristics, and evaluate the overall performance of your mechanical connections.

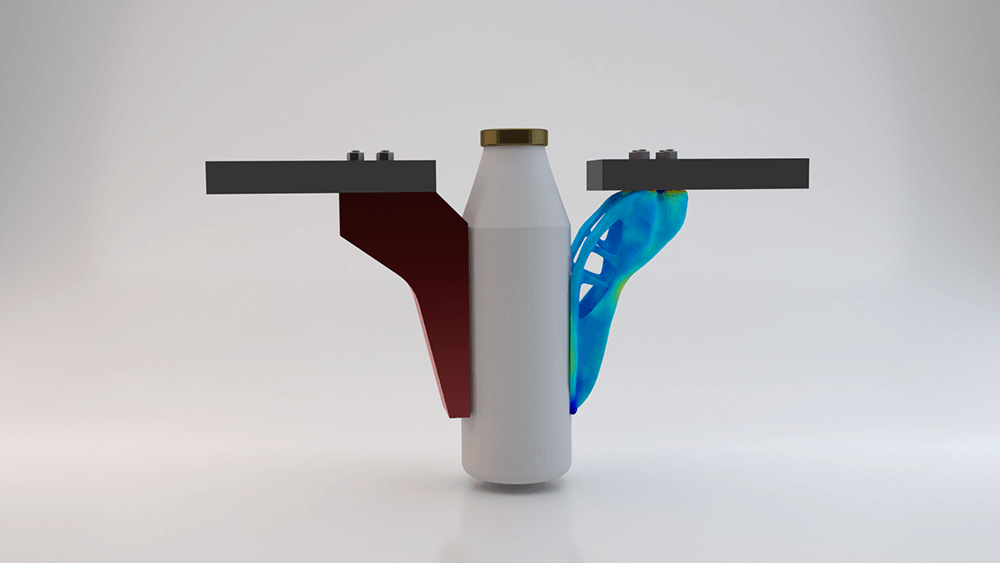

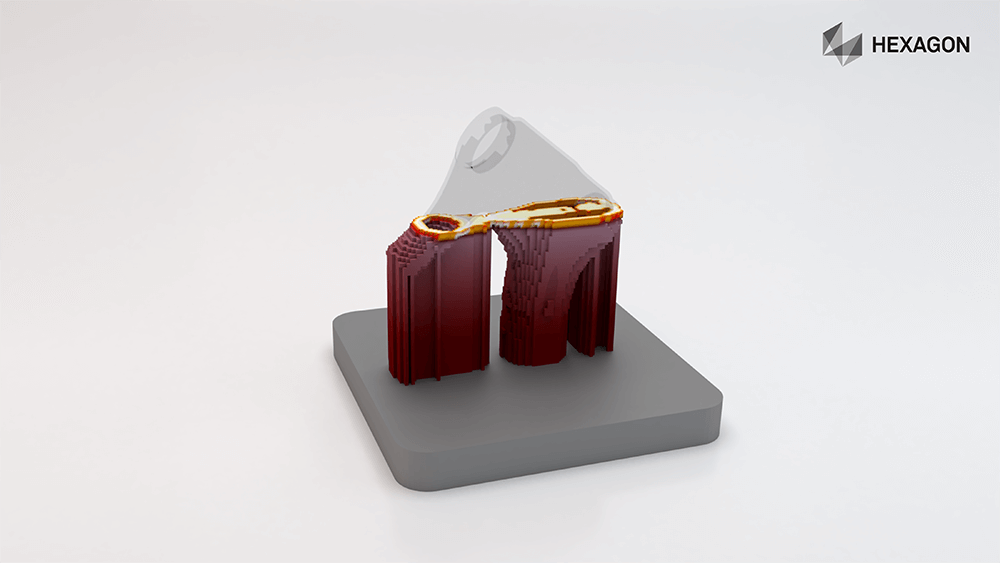

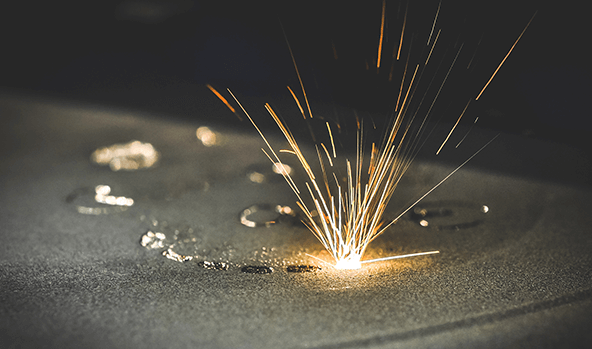

Use our state-of-the-art AM simulation software to evaluate part geometry and processing strategies, in order to predict and mitigate risk of failures and dimensional non-conformance. Perform geometry compensation so that parts distort into tolerance during the AM process. We help the AM industry overcome the AM obstacles and achieve first-time-right printing.

Generative Design

Experience our highly automated geometry optimisation design solution for creating designs perfectly adapted to additive manufacturing. Quickly generate lightweight, manufacturing-ready designs to reduce weight, production runtime and material consumption.

Metal Additive Manufacturing

Be it Laser Powder Bed Fusion (LPBF), Metal Binder Jetting (MBJ) or Direct Energy Deposition (DED), our software solution is designed to predict and compensate for distortion, compute residual stress and analyse temperature distribution throughout the printing process. It extends to include heat treatment, cutting, hot isostatic pressing (HIP) and machining processes. For MBJ it can predict changes during the sintering process and compensating for shrinking. For DED our solution can analyse the coupled thermal-mechanical response within the process and investigate phase transformations during cooling. Overall, it empowers users to industrialise this advanced technology.

Polymer Additive Manufacturing

We offer a dedicated solution for plastics and composite materials to overcome manufacturing issues through warpage compensation. Additionally, sensitivity analyses allow to assess the effect of process parameters on the prediction of warpage, residual stresses, temperature fields, crystallinity evolutions, layer adhesion, porosity and many more to optimise the productivity and the quality of the printed parts.

Forming process can cause very high residual stresses, which are released during the machining process and lead to plastic deformations. A manufacturing process chain simulation that does not consider the forming history and the machining process can lead to significant form deviation.

Machining

Our machining module provides users with subtractive manufacturing simulation, allowing them to simulate the effects of subtractive manufacturing processes such as milling and drilling on the part geometry and the residual stresses. It offers the prediction of the final shape of the component after the machining process.

Our generative design technology enables the free-flowing optimisation of ideas and feasible design possibilities through an almost fully automated optimisation process. It generates lightweight and manufacturing-ready results that save precious resources while ensuring high part performance.

Support Structure Reduction for AM

Designing for additive manufacturing involves minimising the number for support structures. Our generative design technology can optimise components by adapting the geometry to reduce the requirement for support structures. This results in cost reduction and enhanced component quality.

Virtual Manufacturing Products

-

Module

ModuleAn enterprise costing and feasibility solution for sheet metal components.

-

×Human-Assisted autonomyTemplate-based batch analysis.

-

-

Product

ProductSpecial weld structure software for virtual tests and process design for the optimisation of assemblies

-

×Human-Assisted autonomyAutomated application of physics equations for welding process

-

-

Product

ProductSpecialised forming simulation software for virtual testing and process design for component optimisation.

-

×Human-Assisted autonomyAutomated application of physics equations for sheet metal / bulk forming

-

-

Product

ProductSimulation software for process design and virtual testing and optimisation of metal-based additive manufacturing.

-

×Human-Assisted autonomyNC Program generation automated

-

-

Product

ProductMSC Apex Generative Design is an intelligent generative design solution ideal for design for additive manufacturing.

-

×Human-Assisted autonomyAutomated topology optimization and generative design for additive manufactuing

-

-

Product

ProductFTI FASTIncremental provides a detailed solution for validating tooling designs and process parameters prior to cutting dies.

-

×Human-Assisted autonomyAutomated application of physics equations of sheet metal forming and blank development

-

-

Product

ProductFASTFORM® Advanced enables sheet metal part and process feasibility, blank shape determination and spring back prediction.

-

×Human-Assisted autonomyAutomated application of physics equations for blank development and sheet metal forming

-

-

Product

ProductCATSTAMP® provides forming simulation, blank prediction and cost optimisation tools for sheet metal stampings.

-

×Human-Assisted autonomyAutomated application of physics equations for blank development and sheet metal forming

-

-

Product

ProductCOSTOPTIMIZER® Professional is a software that establishes target costs for sheet metal components and tooling.

-

×Human-Assisted autonomyAutomates the method planning and tooling costs for operations for progressive and transfer dies

-

-

Product

ProductEvaluate and optimize the manufacturing process virtually to get to the right fit and function faster in reality.

-

×Human-Assisted autonomyAutomate modeling tasks to reduce time to results

-

-

Product

ProductEliminate the need for part-specific check fixtures

-

×Human-Assisted autonomyAutomate modeling tasks to reduce time to results

-