Metrology-assisted manufacturing

Bring metrology-grade accuracy to industrial automation for more efficient manufacturing processes.

Putting accuracy at the heart of production

See how laser tracker automation gives robots repeatability with accuracy to drive manufacturing productivity.

Ready to learn more?

The ability to intelligently automate production operations is a key promise of smart manufacturing. Hexagon’s metrology-assisted manufacturing solutions use measured data to provide real-time feedback for applications, including robot guidance and machine tool correction.

Smarter industrial equipment

-

Overview

-

Robot guidance

-

Tool correction

Data-driven manufacturing

Manufacturing is moving towards smarter, more autonomous operations from design through production and into service life. Emerging technologies such as AI and machine learning are enhancing the application potential of established technologies, and industrial automation systems are no exception.

Metrology data is a powerful and largely untapped resource for employing greater automation in smart manufacturing environments. From improving the accuracy of industrial robots to correcting machine tool paths to account for tool wear, metrology-assisted manufacturing has a huge range of productivity-enhancing applications on the modern shop floor.

Accurate robot positioning for manufacturing

Industrial robots have been a staple of manufacturing for decades, completing a vast variety of common factory activities from part delivery, palletisation and picking to welding, painting and labelling. Robots are also frequently deployed in assembly operations, where they offer better throughput and productivity.

However, the application potential for robots in manufacturing can be limited by their accuracy. While robots are highly repeatable, their positioning accuracy is sometimes not high enough for more intricate manufacturing operations.

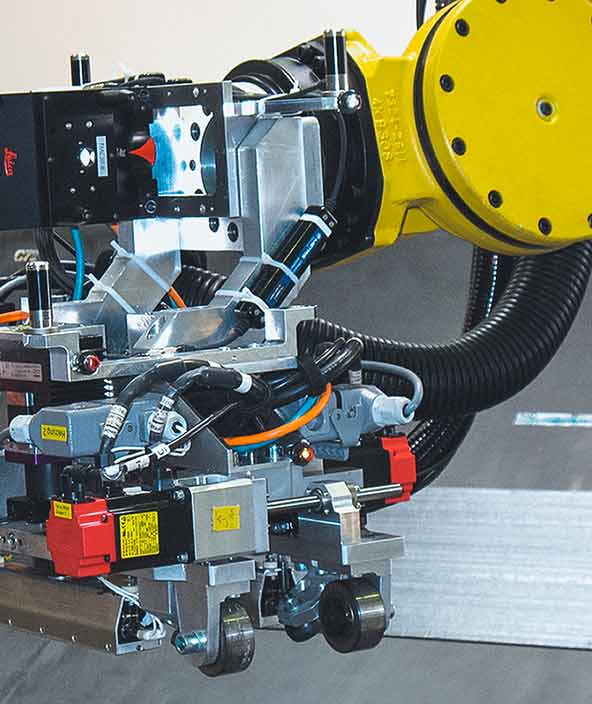

Hexagon’s metrology-grade laser trackers with machine control sensors have the ability to guide industrial robots to a precise position, enabling robots to complete high-precision tasks that open up new fields of application potential. This metrology-assisted manufacturing approach is increasingly common in the automotive and aerospace industries, and robot guidance is beginning to gain traction in other fields as well.

Intelligent correction of machining toolpaths

The ability to leverage existing data to improve outcomes is one of the major benefits of smart manufacturing. Most manufacturers are already capturing some combination of dimensional data and process control information as part of their quality assurance process. Putting this data to work and giving real-time feedback to production allows faster correction and compensation against process variables, automatically correcting the process to minimise scrap and move closer to first-time-right manufacturing.

Hexagon's intelligent machine control solutions use statistical insight from the inspection data of parts coming off a machine tool to automatically adjust machining toolpaths. This enables manufacturers to counter the effects of machine tool variances caused by environmental conditions or tool wear for increasingly autonomous production processes.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.