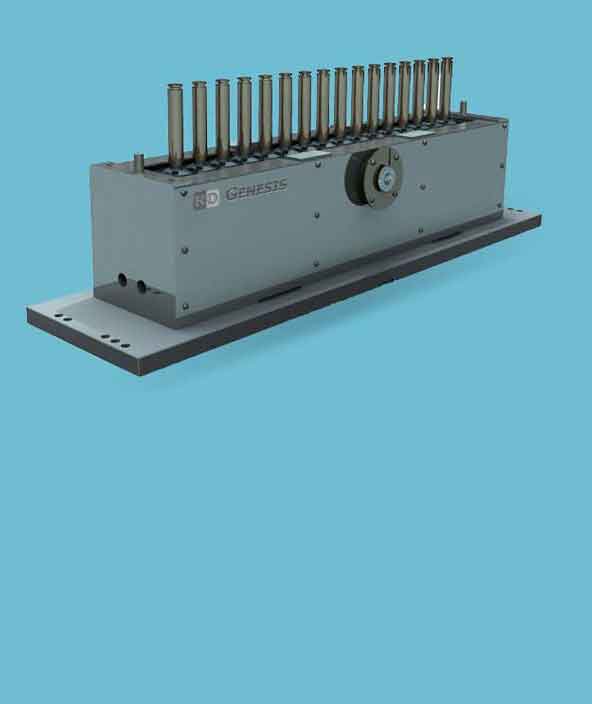

Industrial mould

Accurately design and test industrial moulds

Reliable and efficient industrial moulds start and end with digital systems.

Ready to learn how Hexagon's capabilities can empower your business?

Industrial moulds are a vital tool in part production for a range of materials. As products and materials grow more complex, moulds must follow. To be competitive in the tooling, mould and die industry, quality and efficiency are key. Hexagon’s industrial mould solutions streamline the mould and die development process from design to manufacturing, ensuring accurate manufacturing for both tooling and end products.

Explore capabilities

-

Industrial facilities

-

Infrastructure

-

Manufacturing

Operate and maintain phase

Leverage data from the planning, design and build phases to create an operational twin that connects people, processes and events throughout the entire industrial facility lifecycle.

Construct phase

Maintain a data-driven approach to orchestrate the entire construction phase, creating a 3D model of productivity and efficiency — with higher quality, fewer reworks and less waste — while layering 4D cost and 5D BIM scheduling data throughout the project.

Design and engineering phase

With Hexagon’s innovations in manufacturing technology, users can digitally simulate and optimise product design and engineering to ensure component manufacturability, production productivity and output quality.

Production phase

Maintain a digital thread through production, optimise machine tools, measure environmental variances and prevent downtime with predictive data analyses.

Inspection phase

Automate and digitalise quality measurement with our world-leading metrology hardware and software, creating a bridge between the real and digital worlds.

Digital transformation

Deploy Hexagon’s sensor software systems to transform siloed and disconnected processes into an integrated, data-driven manufacturing ecosystem that captures and creates value across the product lifecycle, enabling new business models and automating workflows to become increasingly autonomous, efficient and sustainable.