Production machining

Empowering machine shops to achieve operational excellence in manufacturing discrete parts, tools, and components on CNC machines, spanning from prototype to production, across industries.

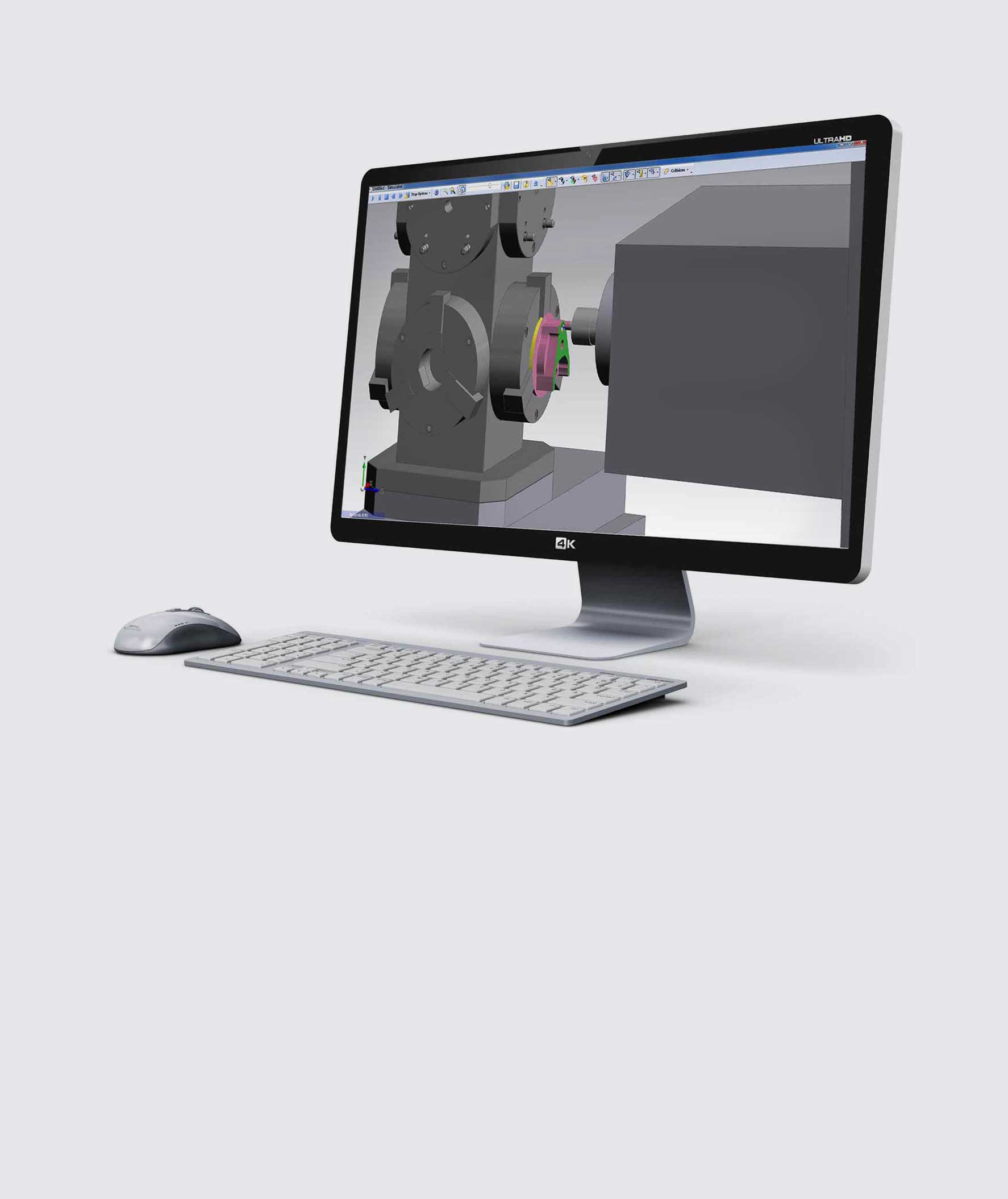

Powering productivity with software solutions

Elevating CNC workfiows for enhanced efficiency and quality assurance

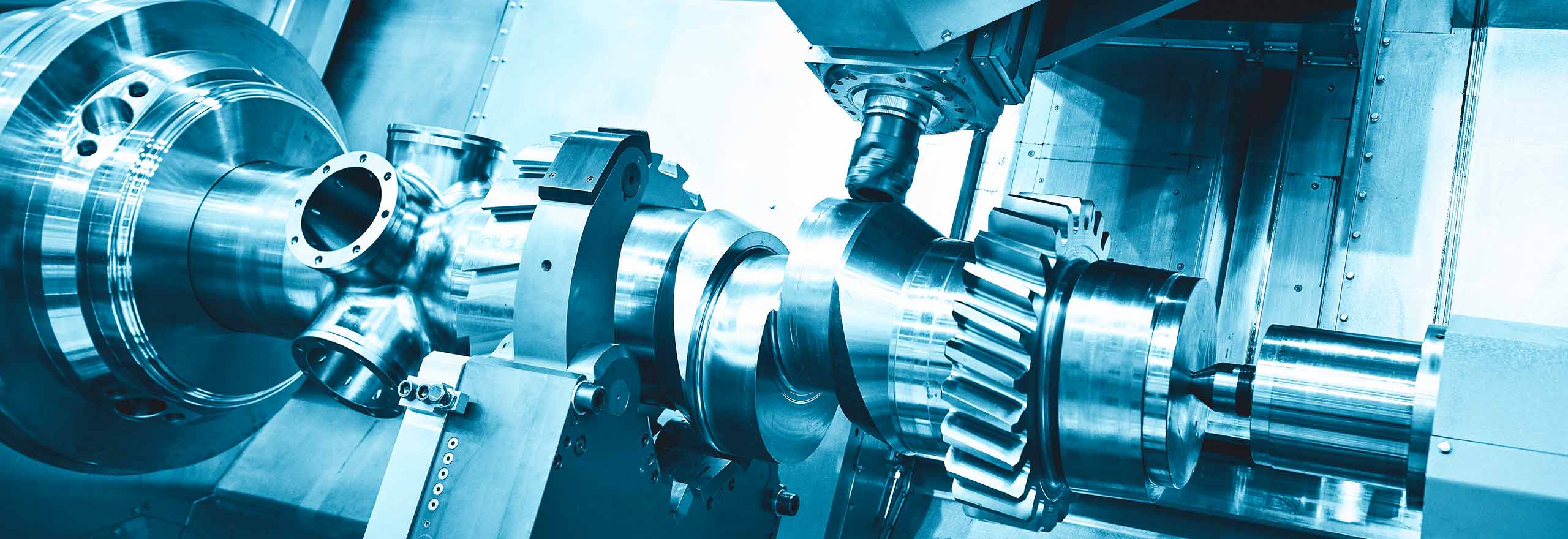

Production machining is the backbone of manufacturing, delivering machined metal parts in high volumes for use in all kinds of products. Hexagon’s CAD CAM solutions for production machining give manufacturers from job shops to OEMs confidence in their processes and ensure delivery of quality parts.

Overview

Production machining relies on volume manufacturing to be cost effective. The key to success in production machining is therefore to ensure maximum machine tool utilisation while minimising rework time and scrapped parts. Machine shops of all sizes need CAD CAM software that is easy to learn and use and provides reliable G-code for the variety of machined parts they are required to make.

Hexagon’s CAD CAM solutions for production machining address a wide range of CNC machining applications including milling, turning and mill-turn machining. Featuring intelligent workflows to assist users during programming, they help ensure optimised production strategies for a wide range of applications.

Designed to be scalable to the needs of the machining centre and compatible with a wide range of machine tool manufacturers, Hexagon’s production machining solutions help machine shops around the world deliver components on time, on budget and on specification.