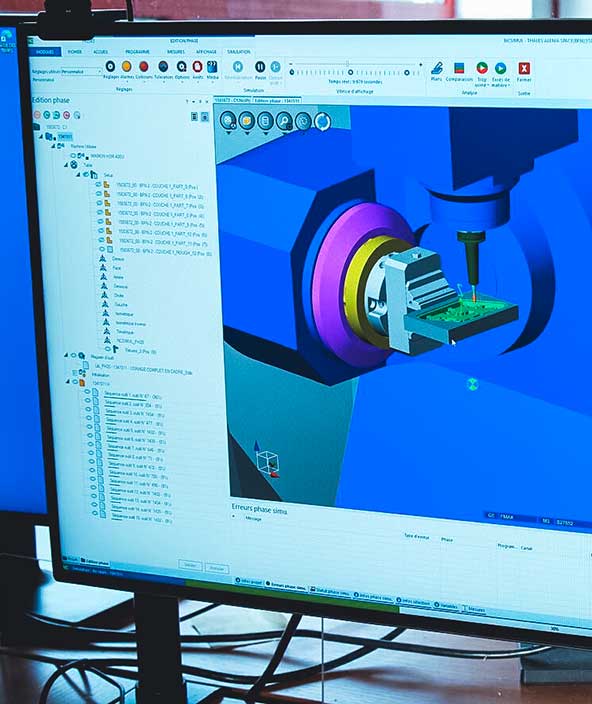

CNC simulation

Use the machine digital twin to test G-code and virtually validate production processes.

Simulate, validate and prove G-code to machine parts with confidence

Control the machining process from NC program to final part with NCSIMUL, the all-in-one CNC simulation software.

By virtually validating the real-life machining environment prior to production, Hexagon’s CNC simulation software helps manufacturers avoid errors, decrease setup times and switch CNC programs between machines to increase shop-floor productivity, reduce costs and move closer to right first time.

Overview

The production process is the most costly area of manufacturing when things go wrong. The efficiency and high throughput of modern machine tools means that simple things like tool wear, changes to environmental conditions or a small error in programming can add up to costly rework and scrap.

At the same time, the preparation and debugging of programs for CNC (computer numerical control) machine tools are tasks that offer tremendous scope for increased productivity. Manufacturers need to maximise machine uptime in order to remain profitable.

Hexagon’s CNC simulation solutions address these challenges using a machine digital twin to test and prove out G-code for CNC machines in a virtual environment. They allow manufacturers to validate CAD CAM programs prior to production to avoid costly collisions and mitigate against anomalies in machine tool behaviour. Proving programs via simulation also reserves machine time for manufacturing operations, minimising downtime for essential equipment.