Mould and die design and manufacturing

Ensure quality in tooling, mould and die with CAD CAM for mould and die design and manufacturing.

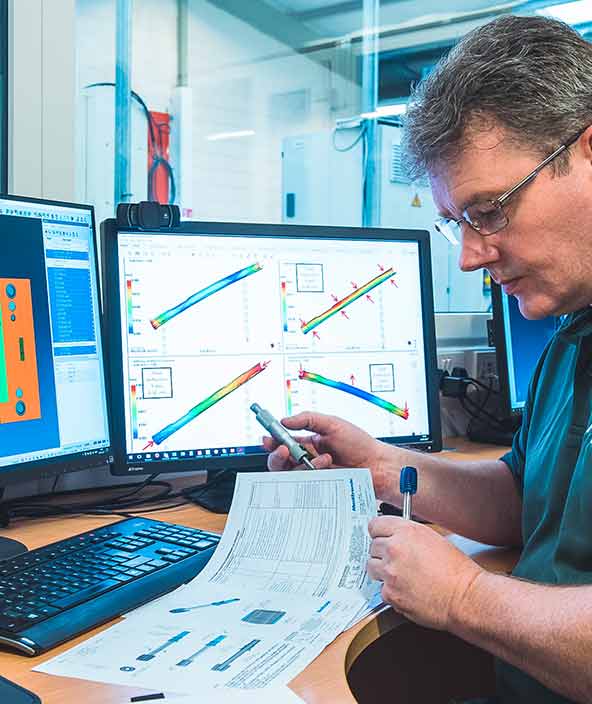

Bringing accuracy to mould and die design and manufacturing

Put data to work to improve accuracy in mould and die design for better quality production.

To be competitive in the tooling, mould and die industry, quality and efficiency are key. Hexagon’s solutions streamline the mould and die development process from design to manufacturing, ensuring accurate manufacturing for both tooling and end products.

Overview

Mould and die is a highly efficient way to manufacture parts in plastics, metal and a number of other materials. Whether using a mould or a die, accurate design and production of the tooling is essential to ensure the quality of the final part. Toolmakers, die makers and mould-makers in every industry therefore rely on specialist mould and die design and manufacturing solutions to ensure efficient production.

Hexagon’s CAD CAM portfolio features dedicated solutions for the 3D design of plastic injection moulds and progressive dies, plastic injection moulding flow simulation, sheet metal stamping, surface and solid modelling and multi-axis machining. They enable mould and die manufacturers to better control every stage of the process, reducing rework and costly production errors and ensuring delivery of projects on time and budget.