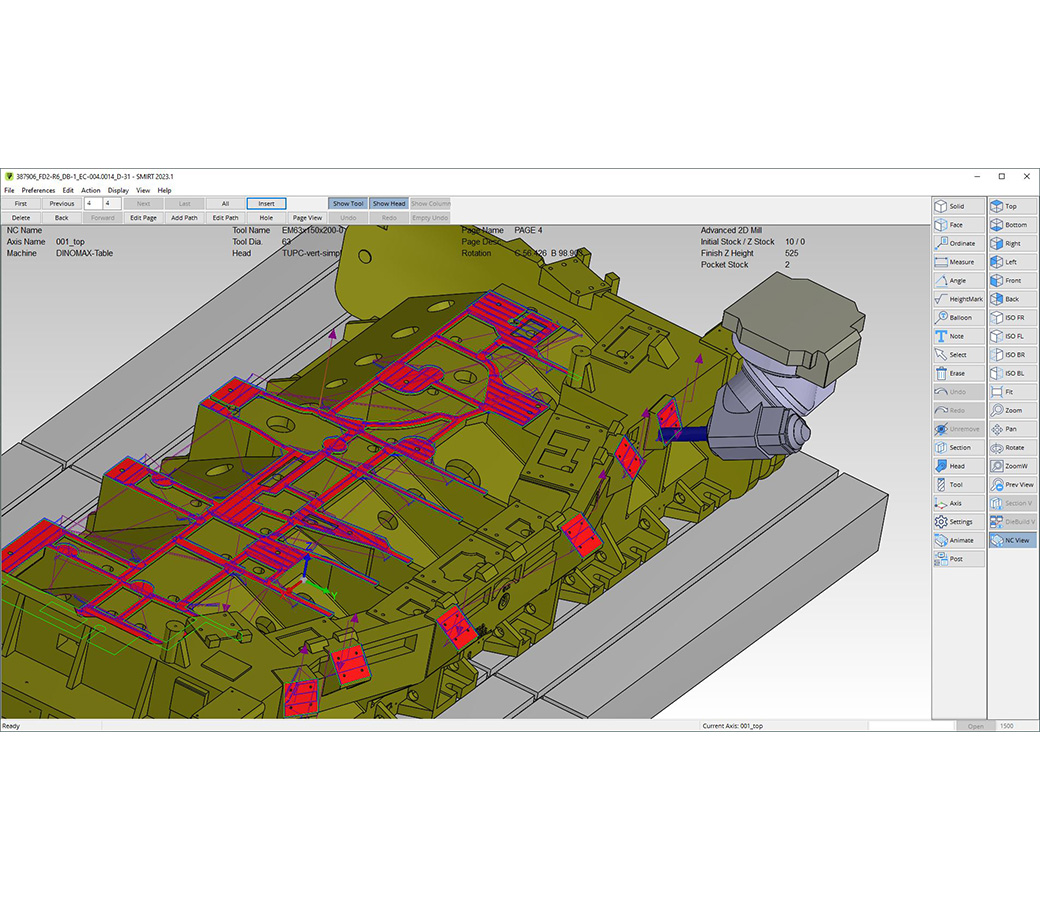

SMIRT NC

Advanced CAM for efficiently machining castings and other die components and mechanical parts

No CAD preparation

With SMIRT NC, you can create toolpaths directly on the solid geometry with no CAD preparation. Perfect for shop-floor environment, fast and safe.

Product capabilities

Features at a glance:

- No CAD preparation

- Shop-floor friendly workflow and user environment

- Integrated with all the other SMIRT modules

- CAM instructions from Process plan.

- Full management of 3+2 axis head positioning

- Real-time collision check with tool, tool-holder, head and machine column

- Smart retract options for enhanced safety and efficiency

- Unique DRAG & DROP technique for planar milling, with efficient management of vertical walls

- New simple, fast and efficient automated paths for planar faces

- Profile milling methods (templates) to capture and utilize best in practice machining techniques

- Various options to complete / edit toolpaths

- Automatic hole drilling based on pre-defined drilling sequences

- Powerful 3D profile milling with several available strategies

- Industry proven efficiency gain.

One solution

SMIRT Nc is fully integrated with the other SMIRT modules. This means that while programming tool-paths, the operator has full access to the entire assembly design and to all the dimensioning, sectioning, annotation, and stock-list navigation functionalities of SMIRT.

In addition, if the manufacturing planning has been defined in SMIRT DieBuild, the detailed process information is available to drive the machining steps, as well as all other shop-floor operations.

One file

Just open the SMIRT main assembly file and do your job. Toolpaths are saved and maintained automatically by SMIRT, and operators don’t need to handle file system allocation of their jobs.

Integrated with WORKNC

SMIRT NC can create all types of toolpaths with the exception of those for 3D shaped surfaces. Operators can create and browse WORKNC workzones directly from SMIRT and will find them listed within the single SMIRT file.

User friendly

Easy to use and learn, designed to be used by all operators, not only by CAD experts.

Visual

Everything operators do in SMIRT is visually realistic: what you see on the screen is what you get in real world.Easy set-up

Select the parts to be machined from the complete assembly file, set the axis as the machine axis or mount components on plates, chose the machine and the head and go to programming. Local machining axis, limit curves and any other CAD preparation are not required.

Effortless 3+2 axis

Once set-up is defined, head orientation and machining plane are automatically computed by just picking the geometrical entity to be machined.

Efficient milling of planar faces and pockets

Select faces to be machined, assign initial, final and lateral stock and apply a strategy: toolpaths are created with very few user inputs.

The legacy Drag&Drop technique is still available, as it’s the fastest method in some cases and allows machining with the same freedom of machine direct controls.

Complete set of milling functions for vertical walls and 3D profiles

The rich collection of strategies to machine extruded surfaces include step down, constant Z passes, plunge milling, follow curve (even 3D) and others, offers a range of options to efficiently create toolpaths with great final quality.

Safe and exceptionally fast

All toolpaths are real-time checked for collisions with the part/s being machined, tool, tool-holder, head and machine column. This 100% collision check, along with smart retract strategies, ensures a high safety level.

At the same time, the workflow from selecting parts to be machined to post-processing the toolpaths is extremely fast.

Unrivaled user friendliness

SMIRT NC’s ease of use minimizes training time for shop-floor operators.

Easy set-up and effortless 3+2 axis

Access to programming is the same as for milling paths. Easy, fast, free from CAD preparation and with no special activity required to handle holes with different directions: just select holes and automatically create paths.

Based on Drilling Methods

User-defined drilling methods are used to automatically compute necessary toolpaths while consistently using best in practice techniques.

Automatic hole feature recognition for exceptionally fast workflow

Drilling methods are automatically assigned to the holes selected for a drilling session. Drilling path computation is performed in a matter of seconds.

Great safety level

Paths for holes that can’t be machined with a given tool in the sequence are not computed, and such holes are highlighted; the operator can easily choose the actions to fix the problem.

In addition, if the drilling path for a hole is not computed, the paths that follow in the drilling sequence can’t be post processed, for a greater level of safety.

Smart retract strategies ensure safe transitions between holes while offering high efficiency.

Unrivaled user friendliness

Select the holes to be drilled and press the mouse button to create drilling paths: in most cases, that’s all the operator is required to do.