Mine Scheduling and Optimising

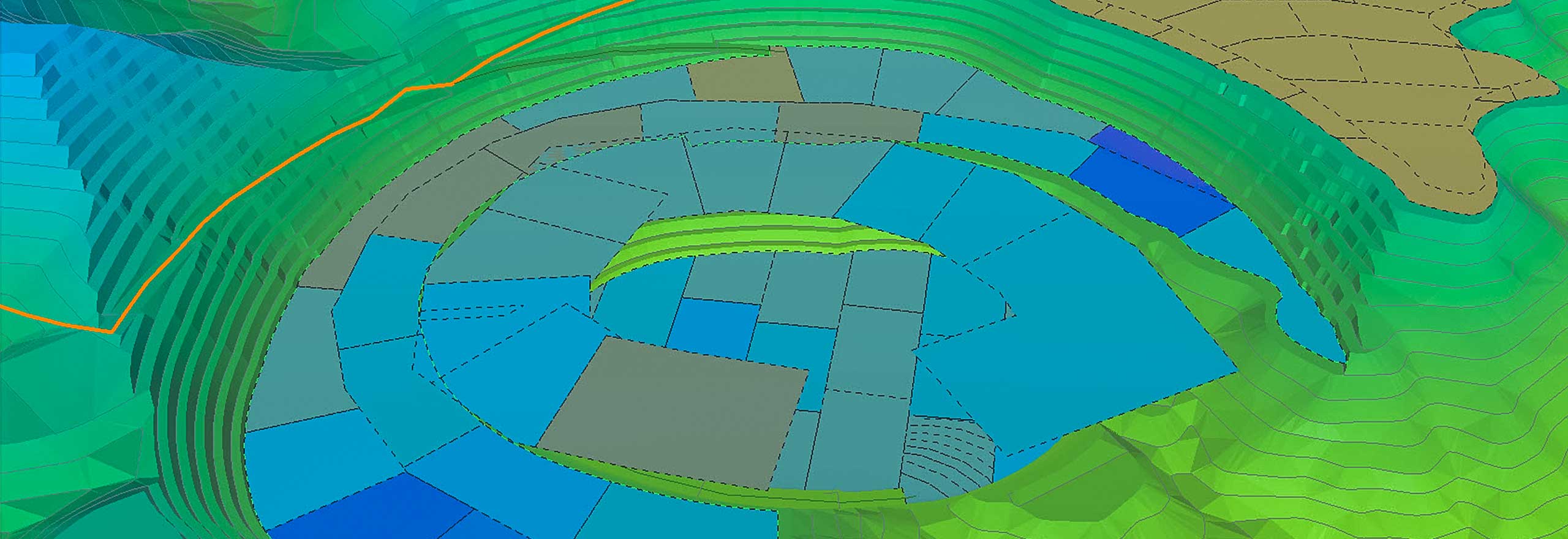

Create mine plans with scheduling scenarios integrated to the block model, haulage and blast design.

Generating the best possible mine plan requires a holistic approach. Monitoring its execution is integral to ensuring an operation stays on track and that business objectives are achieved. Hexagon solutions help to align mine planning with mine operations so mines can realise maximum project value.

Overview

Taking a holistic approach

The mining industry reports hundreds of billions of dollars in revenue every year. Most of this value is forecasted ahead of time and reported in the life-of-mine and budget plans.

Mine planners regularly evaluate and update several mine plans simultaneously. Traditionally, long, medium and short-range plans have been prepared piecemeal by multiple departments, teams and software.

This approach can be difficult without the right software tools focused on open pit design and with no integration to the block model. Manual and spreadsheet calculations are time-consuming, prone to error and inefficient. Scheduling decisions might be based on inaccurate data.

Hexagon software enables a holistic approach, which empowers planning engineers to integrate mine plans across multiple planning horizons. This can improve efficiency at your mine, helping you to make informed decisions by applying timely and accurate data to minimise the variance between plan and execution.

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.