Fette Measures Tablet Press Components Automatically with Leitz PMM-F

Fette Compacting GmbH, Schwarzenbek, Germany

Wide, flat countryside, gigantic wind turbines, bright redbrick houses – so characteristic of the far north of Germany. To industry experts however, the region is also associated with the manufacture of tablet presses. Fette, based in Schwarzenbek, Schleswig-Holstein, has years of experience as a master of this art. Fette tablet presses are used worldwide in the pharmaceutical and related industries. The company inspects tablet press components – such as turrets, for example – on a Leitz PMM-F. The result is increased productivity.

Tabletting technology revolves around compacting – the manufacture of products like tablets, tabs, catalysts or battery ring cores produced by pressing granulate. The components of the tabletting machines have to be manufactured to high accuracies so that tablet pressing can be as precise as possible. The aim is to minimise the number of defective tablets and use the exact dose of what is often an expensive powdered raw material. A more accurately manufactured machine will also be subject to less downtime.

Right from the start: flexibility and accuracy are paramount

Impressing above all with its high accuracy in combination with the flexible QUINDOS software package, a Leitz PMM had been part of the measurement team’s tool kit from 1988 to 2003. Rising production quantities meant that the previous process had to be improved with the help of a universal measuring solution that would satisfy the demands for economy as well as the technical requirements. The primary objective was that the machine should be designed to allow Fette to use it all day to perform special measurements, programmed measuring processes and final inspections. During the second and third shifts, the machine should be capable of carrying out serial measurements automatically, without an operator. The new CMM should also be able to accept components up to a maximum size of 1800 x 1800 x 500 mm.

Everything under control with QUINDOS: PMM-F, automatic feeder and shuttle system

A Leitz PMM-F 30.20.10 proved to be the solution that could fulfil all the wishes. “The PMM-F exactly matches our requirements: It offers a high scanning speed, accuracy, considerably higher productivity and is extremely versatile. In addition, it is equipped with an active vibration damping system, which compensates for the dynamic effects of the workplace environment on the measured component,” says Mangnus Schumacher, Mechanical Engineering Quality Assurance Manager at Fette.

He explains further: “Together with Hexagon Metrology, we designed the PMM-F for automatic processing to increase productivity. We achieved this by combining the system with an automatic pallet system. The question was how we could design the system to be practical for the user. As an absolute QUINDOS fan, it was important to me that our employees would only have to learn one system and no additional control and handling systems. Therefore we chose to use QUINDOS as our primary system. QUINDOS controls all the components: The CMM and the automatic pallet system.”

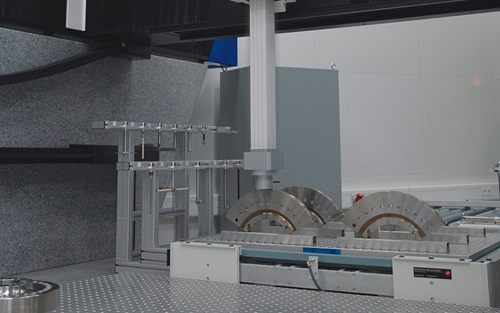

Prismatic components of tablet presses – such as turrets, which have to precisely guide the upper and lower punches, as well as cams and shafts – are measured by the employees on the Leitz PMM-F. Components are brought into the measuring room throughout the day. The metrology technicians compose the list of measurement tasks and load the pallets with the components. The pallets then disappear in the shuttle system. This modern “paternoster” has space for up to 20 pallets. In the evening at the touch of a button, the system feeds the parts to the CMM fully automatically and the machine measures the components during the night. The temperature of the parts is measured. This ensures the results are reliable. The system automatically measures the temperature of the first and one further part on each prepared pallet. After the measuring process is complete, the components are transported back to the shuttle and the report on the results is made available for the next day.

The recipe for success behind the PMM-F: parameterisation and climatisation

Faced with the rapid rise in the number of measuring tasks, the team had to consider in programming the system how to keep the amount of work involved in measuring as low as possible. “The programming was designed to allow us to use parameters in our measurements. Many of Hexagon’s competitors had a hard time coming up with the programmes as we had envisaged them. Some struggled to achieve the required measurement accuracy for the volumes involved. We are speaking here, for example, of turrets with diameters of a metre and 110 drilled holes. None of these holes may deviate by more than 12 micrometres from its theoretical position. This is one of the grounds for housing the whole system in a climatised room. All this is very important to us for a number of reasons: We can be a factor of 10 times more accurate and achieve watertight measurement results, the machine receives better care and requires hardly any maintenance, while, in addition, the components remain clean,” says Anja Lattki, who manages the measuring room where the PMM-F is installed.

The larger tablet press segments are therefore processed during the night almost as if by the help of a ghostly hand, while the PMM-F performs special measurements in daylight conditions. The perfect combination for maximum productivity, thanks to the flexible total solution from Hexagon.

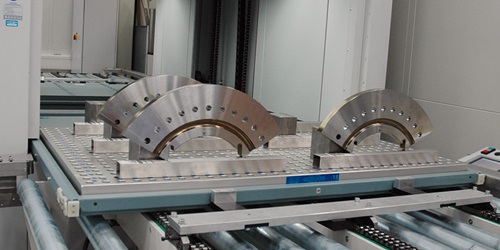

The metrology technicians place the components on mounts. The components are automatically measured during the second and third shifts.

The components are stored on pallets in the 6.90 metre high spacesaving shuttle system.

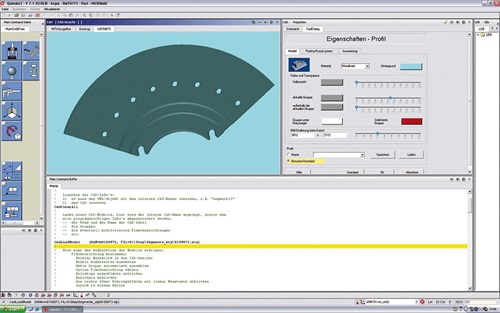

Easy to operate QUINDOS user-interface.

The measurements are taken later and fully automatically o Easy to operate QUINDOS user-interface. n the PMM-F.