NCSIMUL 2023.2

Several new enhancements have been made in the 2023.2 version of NCSIMUL. Here are some of the major highlights:

NCSIMUL Core Enhancements

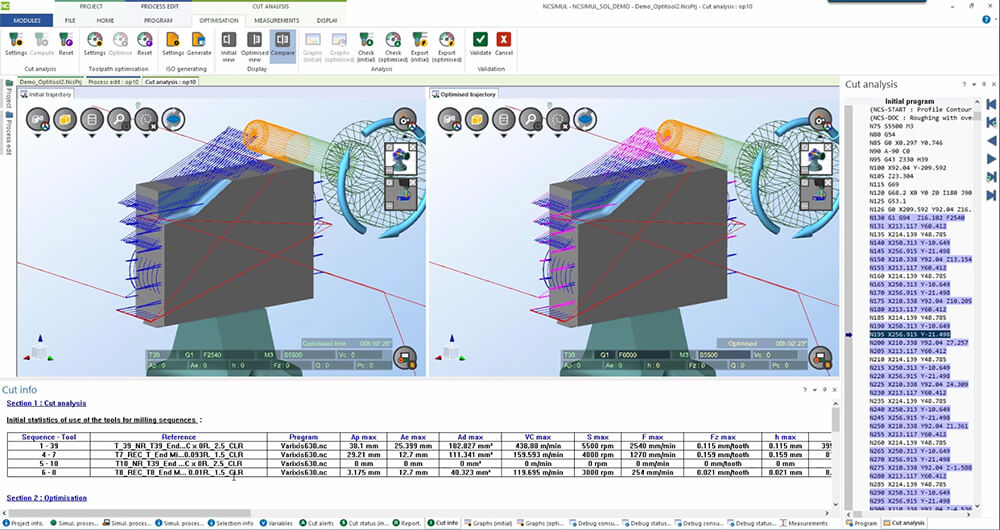

Air Cutting Optimization

The “Aircut” optimization is included in the basic license; the OPTITOOL module is only required to optimize cutting conditions. The “Aircut” optimization reduces cycle times by replacing approach and retract motions that do not remove material in rapid or G1 F max. The “Aircut” optimization is only available for milling and turning programs on single-channel machines.

Benefits:

- Win machining time in air cutting

- Safe optimization of the G-Code

- Easy to use optimization.

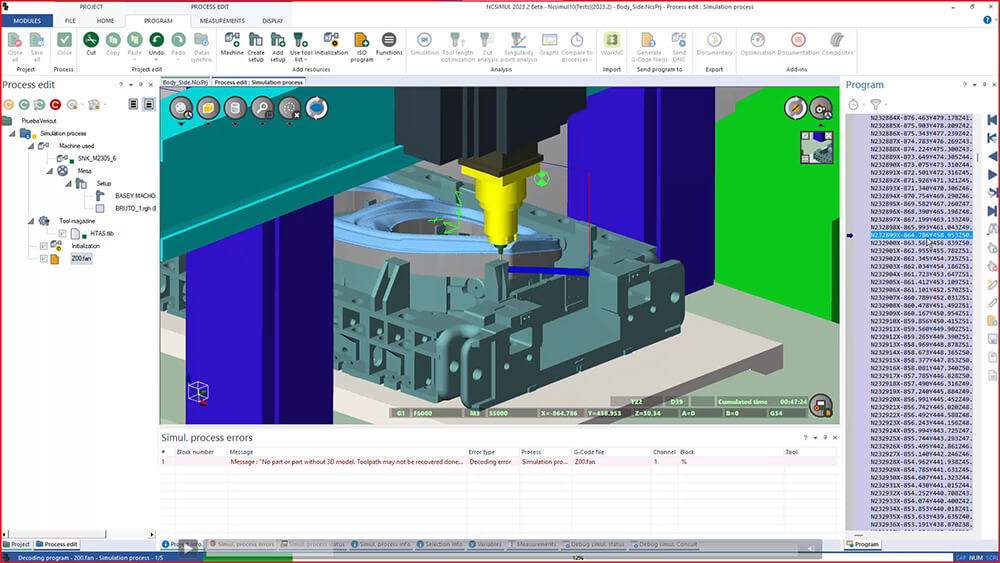

Continuous Decoding

NCSIMUL 2023.2 has a new way of decoding CNC programs. The “Edit while calculating” option prevents the NCSIMUL UI from being blocked when loading programs. The user interface stays accessible during NC decoding, ensuring uninterrupted workflow. Experience Quick display of the program and trajectories. Users can initiate resource editing, such as the tool library, fixture, machine, etc..

Benefits:

- No more wasted time

- Users can start working with the software very quickly

- Suitable for large program

NCSIMUL Simulation Enhancements

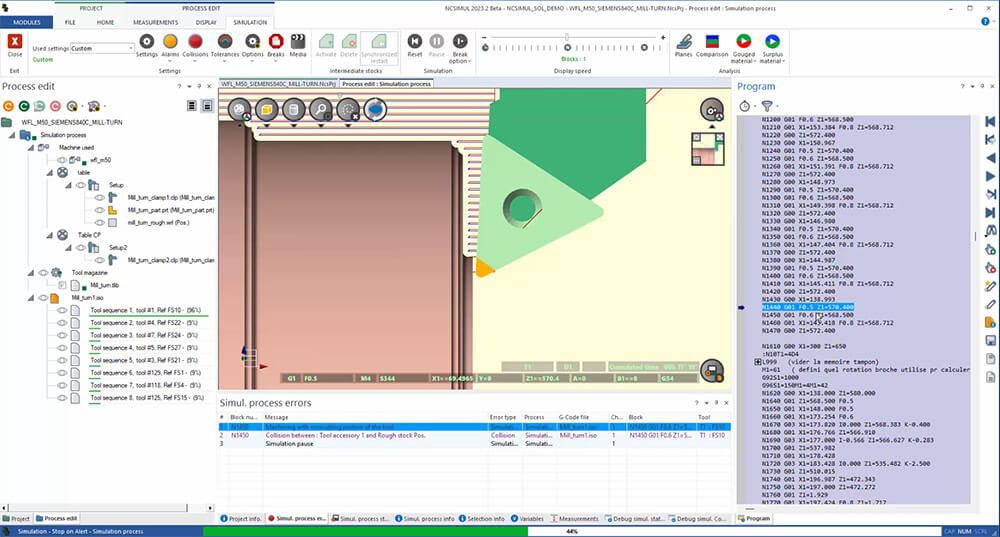

Heavy load on turning insert

Ability to split between cutting and non-cutting edges on turning inserts

BENEFITS

- More realistic simulation with turning inserts

- Control cutter load on the cutting edges

- Control collision on noncutting edges

Collision risk

- New alarm status and clear distinction between collision and collision proximity/risk.

- Benefits better and direct assessment of the collision risk

Maximum Cut Width

- Cut analysis capability is offered in standard simulation.

- New alarm directly in simulation and detects if cut width exceeds a certain threshold.

NCSIMUL User Experience

- Direct button to split 3D view - In one click, direct display the machine view and the tool view

- Validate/Cancel Review - Available directly in the ribbon for the main commands

- New process with previous stock - Direct access in project edition

CAM Interfaces

NCSIMUL 2023.2 supports the following new CAM versions :

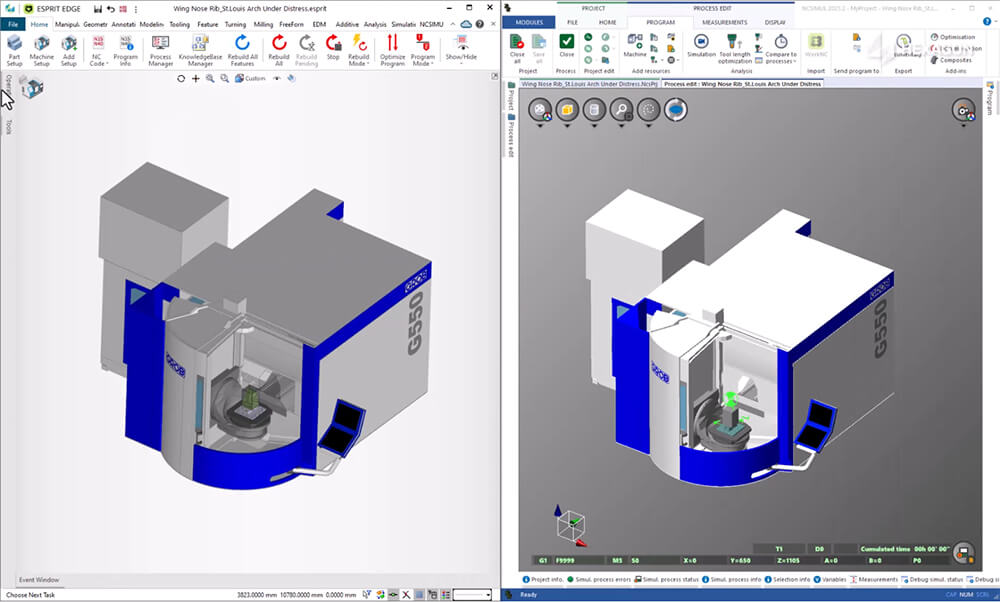

- ESPRIT EDGE 2023.1

- ESPRIT 2023

- EDGECAM 2023.1

- NX 2212

- NX 2306

- CATIA V5-6R2023 ( R33)

- MASTERCAM 2024

- POWERMILL 2024

- GIBBSCAM 2023

- CREO 10

- WORKNC

Digital Twin Preparation

- Millplus - panel simplification (working plane, sub-program, probing cycle…)

- New Panel for WFL machine

- New controller - Fanuc DN Solution (Doosan)

- New cycles on Okuma (grooving, roughing…)

Videos:

- Kinematic definition shared with NCSIMUL

- Automatic setup selection (stock, part, fixture)

- New support of probing tool and circle segment

- Ability to run ESPRIT PP and generate G-Code

- NCSIMUL interface window is not holding ESPRIT anymore

NCSIMUL 2023.2 has a new way of decoding CNC programs. The “Edit while calculating” option prevents the NCSIMUL UI from being blocked when loading programs.

- No more wasted time

- Users can start working with the software very quickly

- Suitable for large program

For users of ESPRIT EDGE CAM software, it is now possible to assemble an NCSIMUL machine using the kinematics defined in Esprit (kinematics file in GDML format). No need to convert kinematics as in previous versions (GDML import in NCMOTION), a single definition for both software packages facilitates updating.

When creating a new machine, if ESPRIT EDGE is installed on the PC (with an active license), NCSIMUL offers to use the kinematics of an ESPRIT machine.