COSTOPTIMIZER Professional

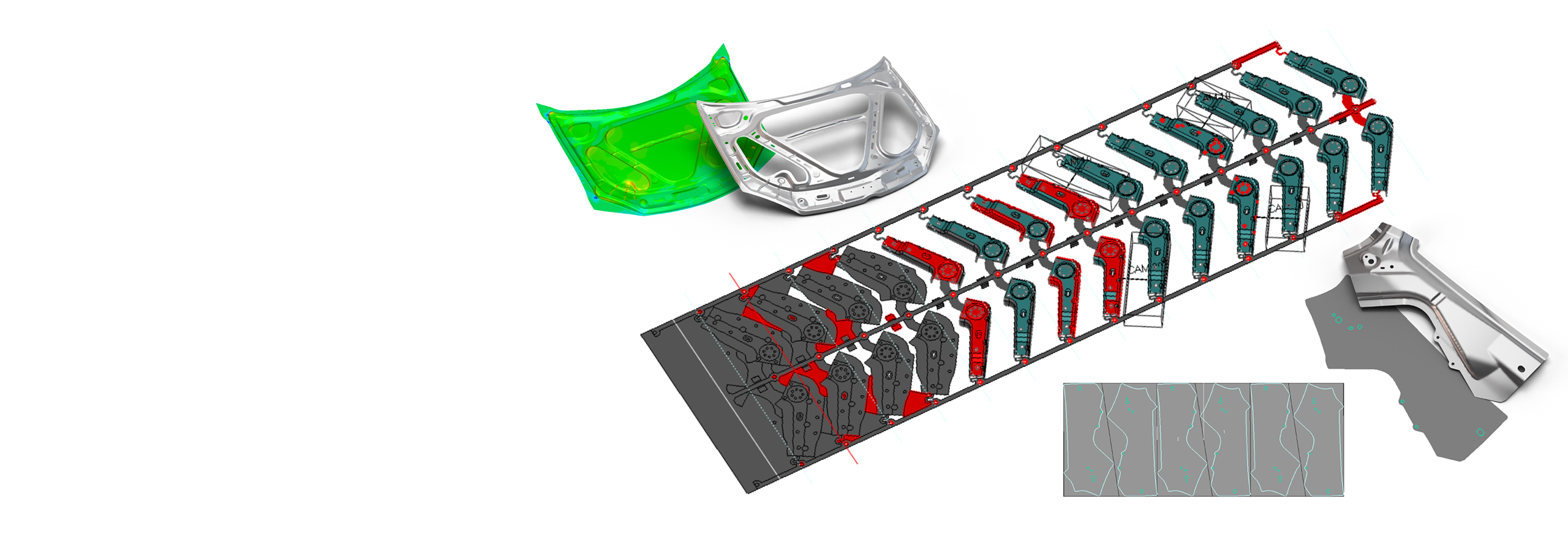

Cost engineering, material utilization, and process planning for progressive and line dies

Sheet metal costing and early feasibility

A solution for sheet metal costing and forming to optimise sheet metal components' design, feasibility, and cost.

Ready to get started?

Cost engineering software solution for sheet metal components

COSTOPTIMIZER range of products

Our COSTOPTIMIZER range of products includes COSTOPTIMIZER, COSTOPTIMIZER Advanced, and COSTOPTIMIZER Professional. Each product allows for exactly the right solution for your costing requirements.Your benefits with the COSTOPTIMIZER range of products

- Establishes target cost for piece price and tooling with a detailed process plan for quoting

- Cost engineers gain self-assurance in quoting and estimating sheet metal components through a consistent and repeatable method for estimating tooling costs with detailed reports that connect to any system.

- A scientific physics-based approach to process planning validated by OEMs and Tier 1 suppliers worldwide.

- Improves quote accuracy to better position your company.

- Suggests product design changes that impact material utilisation.

- Evaluate part manufacturability concerns.

- Generates images to detail die actions in each operation

- Calculates press requirements such as tonnage, bed size, shut height, energy, and selects appropriate press

- Promotes confidence and trust with your customers/suppliers.

-

Articles

-

Case studies

-

Case studyCar seat manufacturer cuts costs and improves quality

-

Case studyStreamlining tool costing and process planning

-

Case studyAdient, Michigan, USA

-

Case studyBoehm Pressed Steel

-

-

Collateral