WORKPLAN for smarter manufacturing

A precision sheet-metal fabricator and machine shop

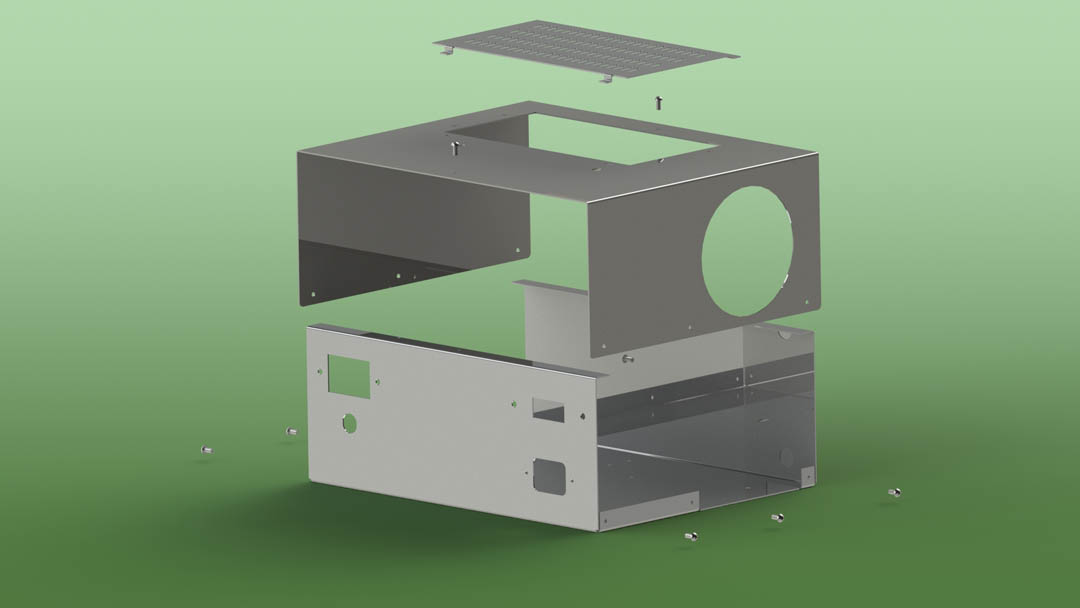

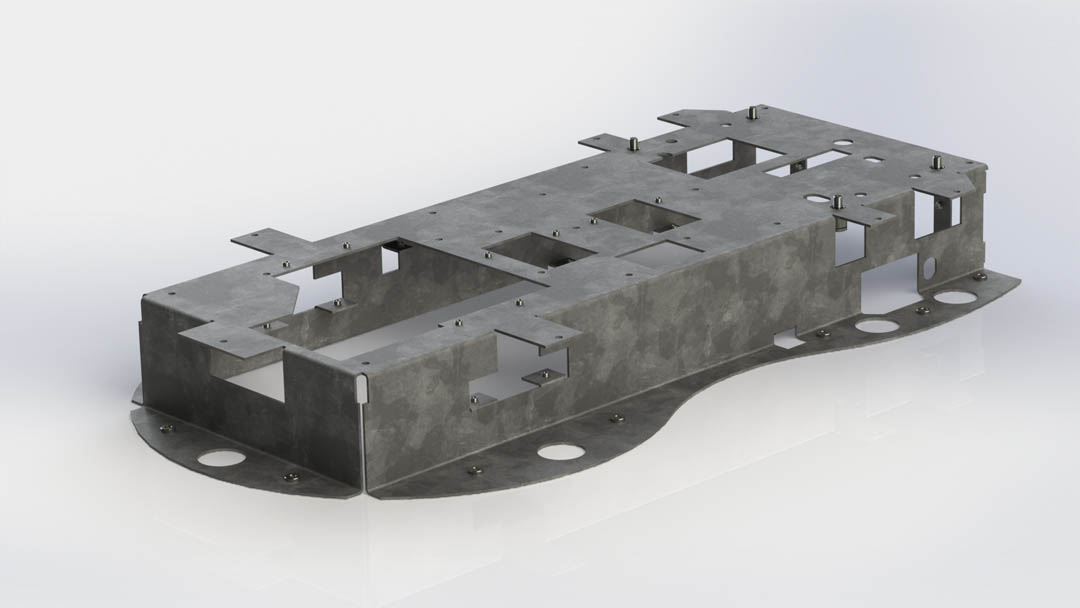

As a job shop that specializes in both precision sheet metal and machining, Hi-Tech Fabricators delivers added value to customers by offering a range of high-quality services under one roof.

“You’re never going to be a one-stop shop for everyone, but machining and sheet-metal coincide quite a bit, so we try to be that one-stop shop for customers who need both,” said Michael Bailey of Hi-Tech Fabricators, based in Milford, New Hampshire.

Opened by Bailey’s parents in 1983, the company has made a point of diversifying and performs a significant amount of work for the aerospace, automotive, defense, and medical industries. Jobs run the gamut from prototype to production and, while the shop doesn’t offer extensive design services, it does help customers refine designs for manufacturability.

“We make anything from simple mounting equipment all the way up to complicated components for robotics,” Bailey said. “Our work is heavily sheet-metal based and driven, with about 80 percent devoted to sheet metal and the rest added on.”

After 37 years in business, the company is adept at fine-tuning processes to gain efficiency.

Within the past year, Hi-Tech Fabricators implemented the WORKPLAN MES solution to pave the way for smarter, more efficient manufacturing — eliminating redundancy and mountains of paperwork in the process.

Forging a digital thread

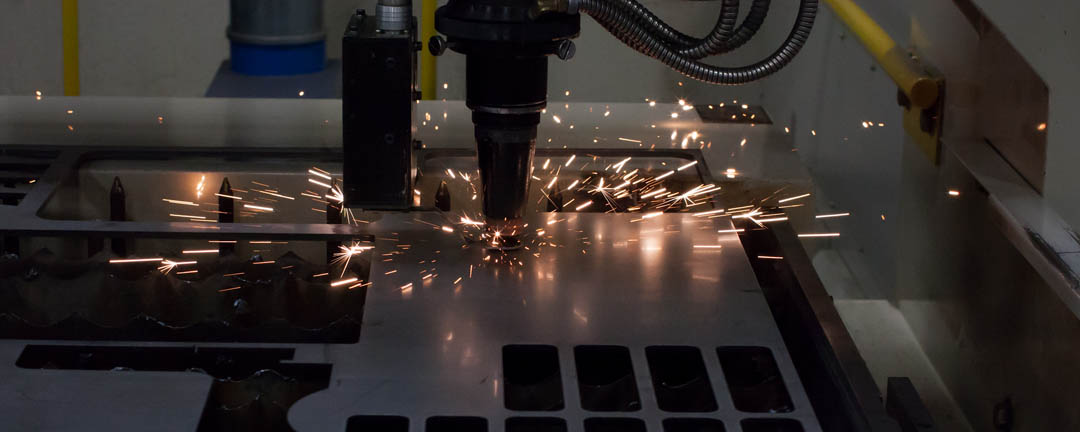

In 2018, Hi-Tech Fabricators purchased an IPG laser cutter equipped with a basic license of the RADAN solution for sheet-metal fabrication.

“RADAN has a lot of automation tools that help us as far as speeding up the programming process, so instead of doing a lot of programming manually, it allows for a lot of it to be automated,” Bailey said.

Once Bailey and his team had taken a “good, hard look” at their new software, the company ultimately adopted RADAN for the programming of all of its machinery — including the IPG laser cutter, a Mitsubishi laser cutter, and two Amada punch presses.

“We wanted to switch all of the machinery to the same software and decided at the same time that we were going to look for an ERP system,” Bailey said. “We had tried a couple of packages that didn’t work out, and then we learned about WORKPLAN. I went with Hexagon because it’s developing smart-shop technology, where everything is tied together.”

One of the best ways for manufacturers to gain efficiency is to improve how well they’re utilizing the data that they already have. While smart manufacturing and Industry 4.0 are familiar buzzwords, what they really boil down to is the ability to collect data in real-time and put that information to good use.

At Hi-Tech Fabricators, WORKPLAN is being implemented to streamline workflow by providing a centralized database for vital information, a hub for inventory management, and a tool for tracking parts in real time as they move through the shop.

“We’re using it for estimating, scheduling, ordering materials, and job organization,” Bailey said. “Before the software, I had a dozen different locations for things,like files, non-disclosure agreements, and programs scattered about on my server; now, all of that is on one place and I don’t have to spend time looking for any of it.”

Simplified inventory management

Various software packages were used by Hi-Tech Fabricators over the years and, at one point, the company used five different independent systems to manage jobs and business data.

“Before WORKPLAN, I’d order raw material that would, for example, have an updated price since the last time I ordered it, and someone would have to manually manage that change on a spreadsheet.

“Now I purchase that raw material through WORKPLAN and the price gets automatically updated in the system. I’m trying to eliminate steps in the process and streamline everything, which saves us time and reduces opportunities to make errors.”

Far more than a conduit for ordering supplies, the software makes it easy to see at a glance what’s been ordered, but is not yet in stock, and how much material has already been dedicated to any particular job.

Icons within the system’s interface change color based upon the status of materials required for a job, which makes missing elements easy to spot. The system lists supplies automatically reserved from stock, as well as the associated cost and supplier. Likewise, it lists missing materials and makes it easy to order from a list of suppliers kept within the system.

As each person who uses the system can create and log into their own WORKPLAN account, the software also makes it easy to identify who did what, and when.

From quote to production

When a potential customer requests a quote, Hi-Tech Fabricators uses a combination of its computer-aided-design (CAD) software and RADAN to generate a job quote in WORKPLAN — which accounts for the raw materials, time, and equipment information needed to generate an estimate.

“What we have is a manual process, but it’s a lot more streamlined than it was,” Bailey said. “We create a quote in WORKPLAN, which automates the process of e-mailing that quote to the customer. If they decide to order, the quotation gets turned into a sales order, the raw materials are ordered or pulled from inventory, and the job is put into a schedule.”

Moreover, if the job requires outsourcing, purchase orders can be generated in WORKPLAN, which will prompt users to follow the steps necessary to lay the foundation for the job.

“All of the drawings and other job information are printed and sent to the shop floor, and WORKPLAN tracks the jobs each step along the way. I can look at the system to see how many processes are left before I can send it out for an outside process or ship it. Tracking slips and delivery notes are also generated in the software.”

With support from the WORKPLAN team, Hi-Tech Fabricators is further fine-tuning its process by establishing a direct link between RADAN and WORKPLAN.

“We’re light-years ahead of where we were two years ago because of the organizational tools that WORKPLAN offers, and the pinnacle will be connecting the software with RADAN,” Bailey said, adding that he’s received top-notch support from the WORKPLAN team.

About the company

Name: Hi-Tech Fabricators

Business: Precision sheet-metal fabricator and machine shop

Web: www.hitechfabricators.com

Key benefits achieved

- Ability to access a range of vital information from a single interface

- Greater ease in ordering and managing inventory

- Increased ability to efficiently track jobs through the shop