Powering the future of aviation with ROTATOR pitch control mechanism

by Xiaobing Hu, Applied Solutions, Hexagon’s Manufacturing Intelligence division

Engineering Reality 2023 volume 2 edition

Empowering Makers for an autonomous sustainable future

Open-rotor aircraft engines aim to achieve the performance advantages of a turbofan with the fuel economy of a turboprop. They operate on the same principal as a turbofan, but the bypass duct is omitted, allowing for significantly higher bypass ratios without incurring the weight and drag penalty associated with a large duct. Open-rotor engines offer significant CO 2 reductions, adopting this type of engine could save 180 million tonnes per year.

Open-rotor engines require accurate fan blade pitch control via an actuation system. This area of control requires the greatest attention to realise potential fuel savings. Current hydraulic systems transfer fluid to the rotating actuator components to control the blade pitch, requiring high-maintenance dynamic seals with the potential for leakages. The consortium has developed a fault-tolerant electro-mechanical PCM, eliminating the need for hydraulics and utilising an ultra-high torque density magnetically geared “pseudo-direct-drive” (PDD) motor, lightweight high-frequency transformer and highly optimised and lightweight actuator system.

The partner companies and areas of responsibility within the ROTATOR consortium are:

Rotator Consortium Members

Safran Customer

Hexagon Actuator mechanical system design

Magnomatics Psuedo direct drive (PDD) motor concept design

Advanced Electromagnetics Permanent magnet direct drive motor concept design

The University of Sheffield Electric drive system sizing

The University of Sheffield Lightweighting opportunities and assessments

Hexagon’s contribution has been the development of the concept and detailed prototype designs for the mechanical elements of the PCM and development of a multi-physics simulation for use in a digital twin. Hexagon’s Romax software was used extensively to design and validate the bearings within the PDD. Hexagon’s Adams software was used to validate the complete electro-mechanical performance and develop the digital twin.

A full-size PCM is being built with the components and sub-assemblies being tested at representative speeds and temperatures. The coordinated research activities from four experienced partners from industry and academia will take the technology from TRL1/2 to TRL4/5.

The high-level objective of the “More Electric Aircraft” is to replace existing hydraulic systems, which present maintenance and servicing challenges with electrical systems as far as possible with respect to weight, size, and tolerance of faults, the goal being to completely remove hydraulic systems from future aircraft.

The major areas of focus for ROTATOR have been lightweighting, reliability, rotating power transfer, and fault tolerance.

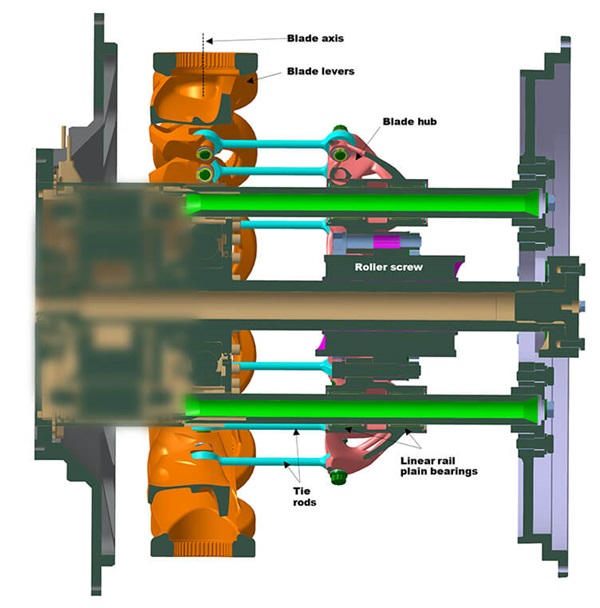

The drawing below identifies the main parts within the actuator mechanism, which Hexagon was responsible for or, as in the case of the blade hub and blade lever, were heavily involved in their design.

In response to a control demand for a change in propellor pitch angle, the PDD rotates the rotor shaft, resulting in linear motion of the roller screw. The blade hub is attached to the roller screw and moves linearly on its rails, pushing the tie rods, which rotate the 14-blade levers and cause the propellor blades to rotate to the desired position.

Romax was used to analyse the many rolling element bearings within the PDD and assess their suitability under various static operating conditions. The analysis accounts for operating temperatures, fault conditions, assembly conditions, and mounting conditions. Romax modelling was later expanded to include modal analysis of the system, static loads on the linear rails for component selection, stiffness analysis of the front mount, and validation values for the digital twin.

During the concept development phase, a methodology was developed by Hexagon to calculate the failure rate of roller/ball screw units. This allowed large numbers of pre-existing components (whole component catalogues) to be scanned, assessed, and plotted. This was used to understand trends, make comparisons, and appropriately size ball/roller screws in the concepts. Having considered the merits of both ball and roller screw devices, due to the much greater power density, it was decided to proceed with a roller screw to the next stage of development. During this stage, special attention was given to the design of end stops to prevent damage to other system components should there be loss of PDD control.

Figure 1. Electro-mechanical pitch control mechanism (PCM) actuator components.

In addition to other responsibilities, Hexagon was responsible for specifying all bought parts within the mechanical elements of the actuator mechanism, including fasteners and circlips, etc., involving detailed consultation with specialist suppliers for the design of the linear rail plain bearings, tie rod spherical bearings and PDD rolling element bearings. This also included providing extensive input on the design of components identified as having potential for lightweighting, either by use of lightweight titanium or composite materials, which included loads, package space envelopes, and hard point/interface information.

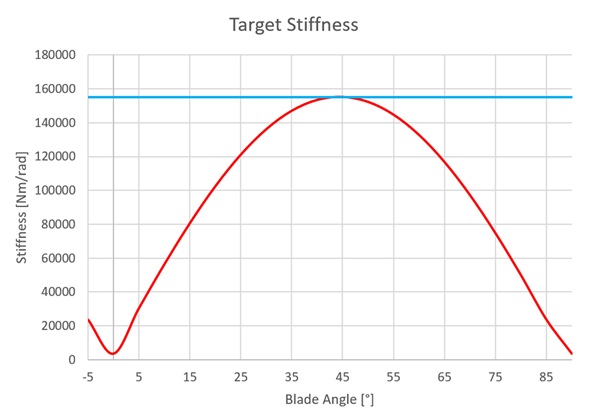

Because of the complex nature of the PCM actuator, the target system stiffness requirement varies depending on the load being applied to the propellor blades. This, in turn, depends on their pitch angle, as shown below. A target system stiffness of 60Nm/rad for each 1Nm of blade actuation capability had been specified. The combined system stiffness was, therefore, set to meet the requirement at the 45⁰ blade angle, where the load is highest.

Frictional losses have been calculated at all component dynamic interfaces. Of these losses, the thrust bearing was found to contribute more than 75% to total system torque losses at 45⁰ blade angle. The below section view through the PCM is shown at this maximum blade load angle position.

Figure 2. PCM actuator system target stiffness.

Figure 3. Section through PCM at maximum blade load position.

A further requirement specified by Safran is that the system should fail safe to the feather position, which is the propellor blade position where no forward or reverse thrust is generated, under all failure mode conditions. Several concepts were developed with a design utilising a localised clamping mechanism considered to be feasible.

A model of the systems in Adams was created to be used as a platform for further technical applications throughout the life of the ROTATOR system. The intent is that the model forms the basis for a Digital Twin, intended to inform the actuator system’s in-service operational and maintenance decisions. In this respect, the Digital Twin aims to supersede the traditional methods used in Reliability Centred Maintenance, which typically use simple, statistical models to schedule maintenance, thereby ignoring the system’s physics and actual operation in real life.

This project advances this important technology critical for the success of new high-efficiency open-rotor engines. Through Hexagon’s contributions, the ROTATOR project achieved a stiffer, lighter, and fault-tolerant PCM design, which will result in greater system efficiency in operation.

Currently, prototype parts and the test bench are being manufactured, with testing planned to begin in Q3 of 2023. The consortium is funded by Clean Sky 2 programme from the EU Horizon 2020 Joint Technology Initiative, which aims to develop and mature breakthrough clean technologies for air transport.

This project has received funding from the Clean Sky 2 Joint Undertaking (JU) under grant agreement No. 886986. The JU receives support from the European Union’s Horizon 2020 research and innovation programme and the Clean Sky 2 JU members other than the Union.

Disclaimer

This Document reflects only the author’s view and that the JU is not responsible for any use that may be made of the information it contains.