Phasers set to stun

The Wand Company - United Kingdom

Contact us

Twenty-third century phaser meets twenty-first century laser as Hexagon Metrology measuring equipment helps inventive consumer electronics company blur the lines between science fiction and science fact.

In 2010, a small start-up company created a moment of magic on British television screens by showcasing their product on the popular BBC series Dragons’ Den. The programme invites budding entrepreneurs to pitch ideas to five potential investors, known as the ‘dragons’, to secure financial and strategic support for the development of their business. When The Wand Company entered the den, no-one was expecting what happened next.

The dragons – along with the audience at home – watched spellbound as company directors Richard Blakesley and Chris Barnardo demonstrated their unique product: a magic wand remote control with the ability to operate standard electronic devices with a few small movements.

Using a universal learning remote control chip, the device could be trained to give the illusion of a functioning magic wand. The novelty of the product certainly impressed the investors, with all five making offers to The Wand Company.

From fantasy to the future

Following their television appearance, The Wand Company experienced a surge of interest and with a successful product under their belts, the team went back to the drawing board in search of their next project. In 2012, the company launched a new remote control based on the ‘sonic screwdriver’ device featured in cult science fiction serial, Doctor Who. The appeal of this product hinged around the authentic appearance that proved a draw for sci-fi fans the world over, as Barnardo explains:

“For our first sonic screwdriver, the model used by the Eleventh Doctor, we simply used photographs and measurements that we found on the web to design the product. The response was positive – we had emails from customers asking if we could produce another sonic screwdriver, the one that the Tenth Doctor used. It struck us that the best way to make a really accurate replica might be to find the original prop used in the show and create a 3D scan of it – which is where metrology comes into the story.”

Engineering authenticity

The Tenth Doctor’s sonic screwdriver was launched in 2013, and its speedier development cycle convinced the team that 3D scanning was the most efficient way to develop new products with the accuracy their audience demanded. By scanning the original props, The Wand Company could create an accurately measured base for their product to be designed around using CAD modelling software.

In 2014, the team embarked upon their most sophisticated product design to date: the Star Trekphaser remote control. It was while travelling to California to inspect an original prop from the classic 1960s Star Trek series that Barnardo and Blakesley first came across Hexagon Metrology’s non-contact laser scanning equipment.

Permission to scan

Using unique and often valuable original props as models presented its own set of metrology challenges, as the team discovered during the visit. As Blakesley explains, “When you are working with original props, they can be very fragile – you really don’t want to be messing about with them. Non-contact scanning is a must, and if we can avoid using reference markers or surface treatments, we are much more likely to gain access to the genuine props.”

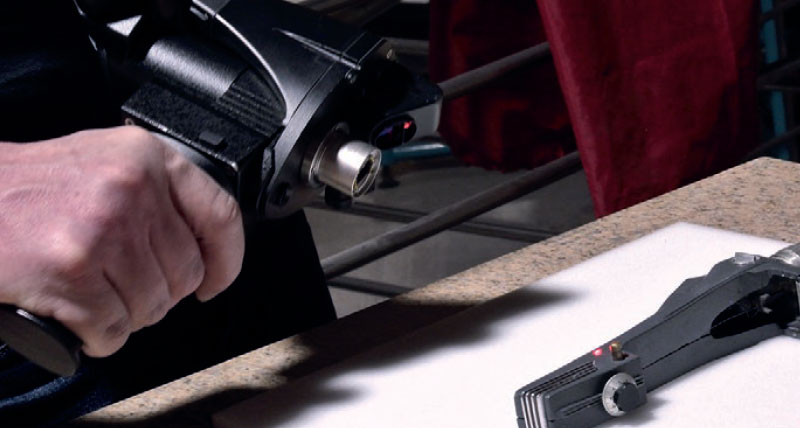

During the course of their work in the USA, The Wand Company team had two contrasting experiences with non-contact scanning technology. On one occasion, they used a structured light scanner to take measurements, while for the phaser they arranged to meet the prop’s owner at a studio that had a Hexagon Metrology ROMER Absolute Arm with integrated laser scanner.

For Blakesley, a major difference immediately springs to mind: “Where the structured light scanner required us to powder the prop to get any kind of quality data, the ROMER Absolute Arm enabled us to capture all the detail without treating the surfaces at all. It was also much faster than the structured light scanner, and I’d say it provided better data too.”

“Using the ROMER Absolute Arm was much more of a hassle-free process,” Barnardo agrees. “And really, when you are handling near-priceless props, dusting them is not something you want to do.”

Transportable information

While the ROMER Absolute Arm with integrated scanner’s high point acquisition rate made scanning the prop a quick and easy process, so too was the export of this point-cloud data to the CAD modelling software – thanks to its straightforward multiplatform compatibility. As well as the benefit of accurate dimensional information, this process also allowed The Wand Company to make corrections for any imperfections or damage on the prop during the design stage, before passing the product design to a manufacturer in China for production. The result is an idealised version of the original, which lives up to fans’ expectations, and Blakesley believes that he has found the right technology to support the company’s future endeavours.

“We were really impressed with the quality of the scan data and the speed of the scanning process, both of which were superior to the structured light scanner. Given the choice, we’d certainly be looking to use the Hexagon Metrology laser scanner again.”