Effect of fibre waviness defect on composite coupons

by Bram Noordman, R&D Engineer, Netherlands Aerospace Centre, Emilie Storms, Product Marketing Manager, Hexagon’s Manufacturing Intelligence division

Engineering Reality 2023 volume 2 edition

Empowering Makers for an autonomous sustainable future

Royal Netherlands Aerospace Centre (NLR) has been a centre of innovation expertise for more than a century. The company works to achieve sustainable, safe, efficient and effective aerospace operations.

NLR is unique in aerospace innovation because it has state-of-the-art physical testing facilities that allow it to conduct in-house research on aircraft like airplanes, helicopters and unmanned aerial vehicles (UAVs). The company’s services cover the entire development chain from analysis and research & development to qualification and certification.

From its main offices in Amsterdam and Marknesse, plus two satellite offices, NLR helps to create a safe and sustainable society. It works with partners on numerous programmes in both civil aviation and defence, including work on complex composite structures for commercial aircraft.

As part of the company’s continuous engagement in innovative and practical solutions, NLR recently conducted a national funded project called “Circular aerospace: product innovation in the aerospace industry” focusing amongst others on virtual testing to support and accelerate qualification and certification of materials and components to reduce the required number of physical tests, costs, and risks.

Simulation minimises risks of defects, reduces time and costs

Manufacturing aircraft components can generate defects — such as fibre waviness — that can arise due to factors like uneven curing pressure, resin shrinkage and ply buckling prior to curing. Unlike in-plane fibre waviness, out-of-plane fibre waviness implies some undulation of the fibres through the thickness of the composite coupon. Because testing at the coupon level is the basis of NLR’s building block approach, employees must perform numerous screening tests to select the appropriate composite material candidate and determine the composite ply and laminate strength and stiffness for different environmental conditions before continuing up the pyramid.

The number of tests, however, further increases in the presence of defects in composite components, to evaluate the effect of these defects on the composite response at coupon level and further up the test pyramid. To reduce the number of required coupon tests, NLR collaborated with Hexagon, relying on its simulation to accurately predict the strength and stiffness of as-manufactured composite coupons while considering manufacturing defects. The simulation approach also helps to reduce the time and costs wasted on otherwise scrapped components.

Experimental measurements and non-destructive inspection of fibre waviness

NLR team members analysed an existing plate with suspected fibre waviness at two areas caused by pressing a material into the plate. “To examine the fibre waviness, NLR performed ultrasonic C-scans of the plate at a frequency of 5 MHz,” states R&D engineer Bram Noordman. “In the two areas of fibre waviness inspection, our technicians used a higher frequency (10 MHz) and studied additional cross-sectional B-scans”.

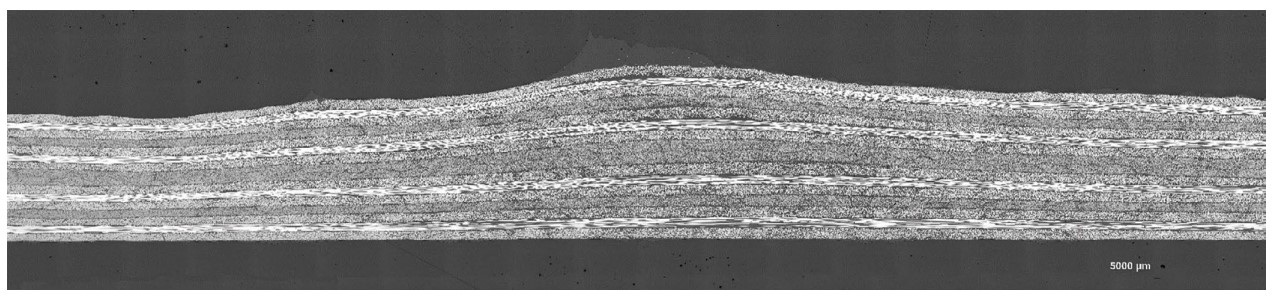

Figure 1. Light microscope image used for out-of-plane fibre waviness inspection.

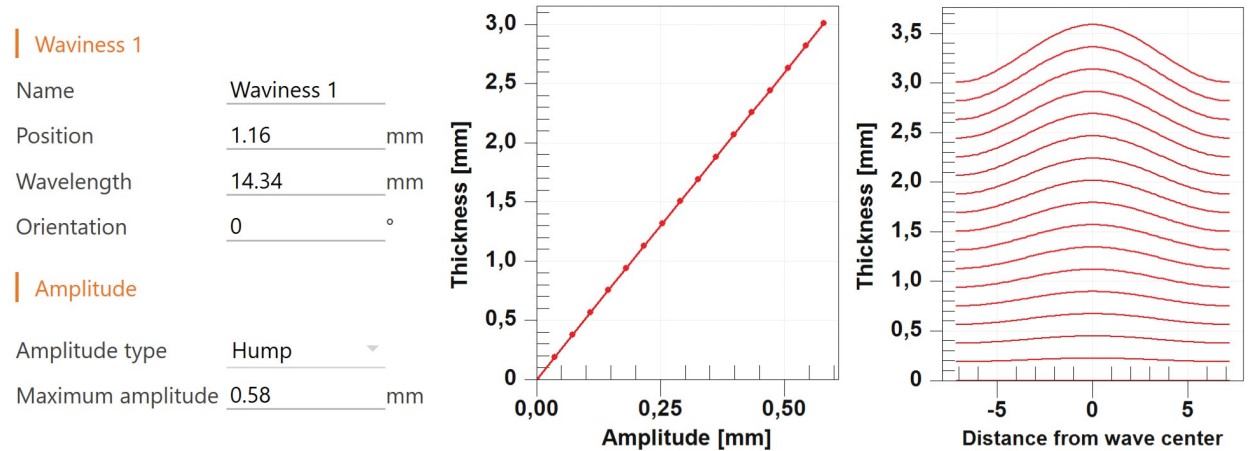

Figure 2. Definition of the out-of-plane fibre waviness in Digimat-VA.

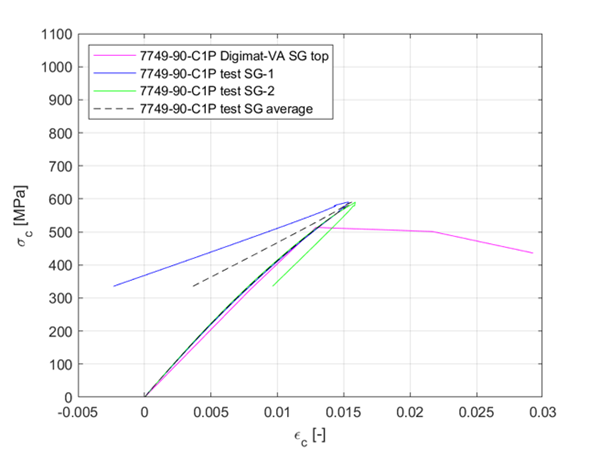

Figure 3. Comparison of the physical (black: average of 2 back-to-back strain gauges) and virtual (pink) results of the UNC test of the coupon without outof-plane fibre waviness.

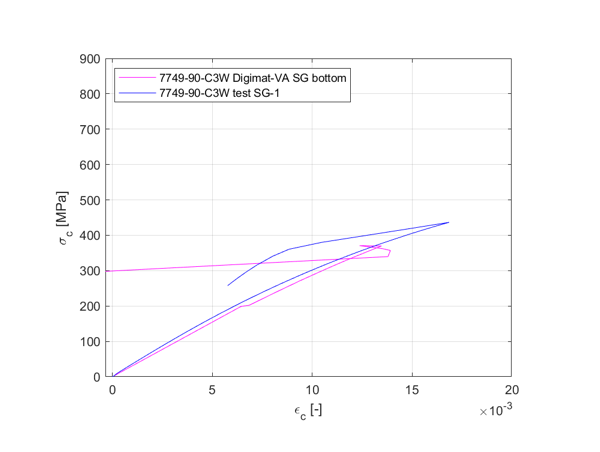

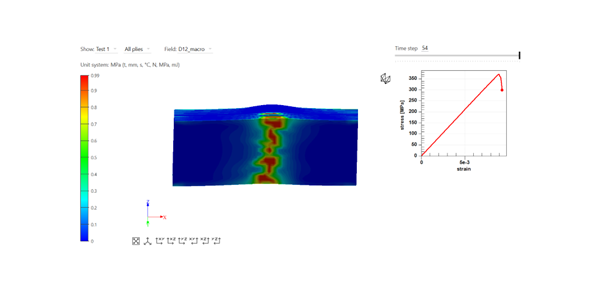

Figure 4. Comparison of the physical (blue) and virtual (pink) results of the UNC test of the coupon with out-of-plane fibre waviness.

Figure 5. Comparison of the physical (left) and virtual (right) damage pattern of the UNC coupon with out-of-plane fibre waviness.

With the help of non-destructive plate inspection, NLR selected twenty locations where unnotched compression (UNC) coupons were cut from the composite plate — with and without fibre waviness, at 0° and 90° with respect to the reference layup direction. The layup consisted of 16 unidirectional plies with the stacking sequence of [45/90/- 45/0]2s. Employees physically tested the UNC coupons in compression according to test standard ASTM D6641 in an Instron 5989 test machine to determine the laminate compressive strength and modulus at room temperature dry condition. The team based the coupons’ dimensions on averaged thickness, length and width measurements with a digital caliper.

Additionally, NLR used spare samples to measure composite density and fibre volume fraction according to the ASTM D792 and ASTM D3171 standards. The team also used specimens for light microscope research to determine waviness parameters, like wavelength and amplitude, as seen in Figure 1.

Digimat-VA provides comparison and validation with virtual predictions

Developed by Hexagon, Digimat-VA empowers engineers to virtually screen, select, and compute the virtual allowables of composite materials — its workflow mirrors any physical testing campaign. It starts with the definition of the test matrix, which consists of the number of materials, layups, coupon tests, and environmental conditions that need to be tested. Rather than being tested experimentally, the team virtually evaluates the test matrix with the corresponding simulations. The simulation requires the definition of the Digimat material and finite element models. Finally, the team analyses simulation results and extracts composite coupon strength and stiffness.

Digimat-VA has suitable materials and tests databases that add to the ease of the project definition. In the scope of this study, the Digimat model of the AS4/8552-UD material is already characterised and available in the Digimat-VA material database. NLR selected the unnotched compression test from the available tests database, and the corresponding FEA model was created according to the ASTM D6641 standard.

Among the different defects that employees can assign to the virtual test, it is possible to define a waviness defect by its position, wavelength, and orientation. The waviness amplitude can be described in five different ways, of which a gradually increasing amplitude through the thickness is used in the current study. Figure 2 represents the waviness definition, where the material orientation of the elements in the wavy area is adjusted to follow the ply undulation. In areas where the fibre waviness leads to a varying thickness of a given ply, the fibre volume fraction is locally adjusted with locally additional resin for the same amount of fibres.

In addition to evaluating the compressive strength and stiffness, it is possible to perform local post-processing in Digimat-VA. Figure 5 shows the shear damage pattern

visualisation of the coupon with fibre waviness — and illustrates that it corresponds quite well to the physical failure location. Digimat-VA makes it possible for technicians

to analyse different types of damage in each ply through the thickness of the laminate at the chosen analysis time step.

Building on strength and stiffness simulation success with improved accuracy

The findings of NLR’s physical and virtual coupon tests show that the compressive strength and stiffness of composite coupons with fibre waviness are much lower than those without fibre waviness. Digimat-VA accurately predicts the composite coupons’ compressive strength and stiffness both with and without fibre waviness. Going forward, this means that NLR employees will only need to perform minimal physical tests for validation.

“Looking ahead, says R&D engineer Bram Noordman, NLR may opt for additional sensitivity studies and use the advanced progressive failure model to further investigate if the correlation of the strength and stiffness predictions can be improved. The organisation may also increase the accuracy of its coupon waviness parameters —such as the wavelength and amplitude by employing industrial CT-scans”.

“Digimat-VA accurately predicts the composite coupons’ compressive strength and stiffness both with and without fibre waviness. Going forward, this means that NLR employees will only need to perform minimal physical tests for validation.”