Multisensor metrology comes of age

Advances in capability and software make multisensor mainstream

Contact us

If you were to ask a typical user in the industry what “Multisensor Metrology” means, you are likely to get a variety of answers. An unscientific survey at a recent metrology training class proves the point. When asked to explain what Multisensor Metrology is, the student’s answers included “multiple ways to probe a part” “using part temperature sensors” “a machine that has multiple uses” and “different mechanisms inside the probe”. The reality that the term is not intuitively understood points to the fact that this area of metrology deserves some explanation.

Historically, when manufacturers talked about multisensor measurement, this strongly implied a vision type machine that had one or more additional sensors, such as the Brown& Sharpe Optiv series which feature a touch probe or a laser point probe. Thus, multisensor could be as simple as combining vision and touch probing on a single machine, a capability that has been around for many years. However, in recent years the exploding variety of probing technologies has pushed this description to encompass many different kinds of measurement devices, from traditional CMMs to vision machines—as long as they contained more than one type of sensor.

The reality of multisensor metrology today is best described as hardware and software capability and inspection technique, and not a specific type of metrology platform. This makes Hexagon Manufacturing Intelligence, with our wide selection of high-precision brands and experienced staff, particularly adept at configuring a multisensor solution to countless numbers of applications. Also, as we will explore in this article, various types of convergence means multisensor technology has made different types of metrology platforms more similar (and more capable) than ever.

Ask us how multisensor technology can benefit your business

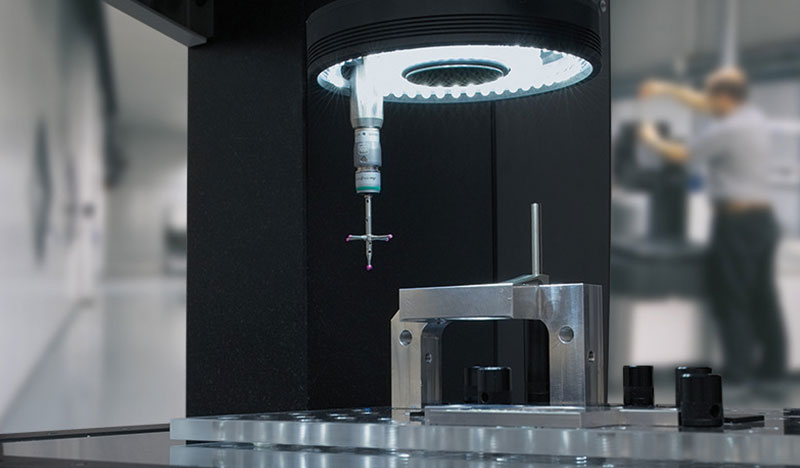

As mentioned previously, traditional vision based measurement platforms have incorporated multiple types of sensors for years. You might call them the original multisensor platforms. Some high-end systems, like the Brown & Sharpe Optiv, are literally bristling with four or more different types of sensors, from vision to touch and various types of contact and non-contact scanning probes.

Recently with the advent of interchangeable non-contact probes for traditional CMMs, you will regularly find CMMs of all sizes and configurations from small bridges such as the Brown and Sharpe Classic to the largest gantries such as the DEA Lambda sporting touch, analog scanning, laser line and even video probes on the same system.

Various multisensor probes

The Optiv's multisensor platform that includes (left to right) touchprobe, camera and white light sensor.

In many cases, similar or identical sensors are available on both platforms. Basic sensor types that may appear on either type of platform include:

- Vision: A camera based sensor that measures using the pixels in the camera image.

- Touch Trigger: A sensor that returns a single measurement point by touching the part

- Analog Scanning: A sensor that moves a tip over the surface of the part and returns a dense line of measurement points.

- Laser Point: A non-contact sensor that returns single points of data via a laser beam.

- Laser Line: A non-contact sensor that sweeps a laser line over the part to return many points of data.

- White Light: A non-contact sensor that uses a focused white light (light of all wavelengths) to return a highly precise measurement point of a fine surface.

It might seem obvious that if your system has multiple types of sensors that you ought to be able to use them in a single inspection program—leveraging the relative advantages of each type of sensor on a complicated part. However, this has not always been the case, either because the software could not support a multiple sensor setup, or the hardware could not, requiring multiple controllers on the same machine.

It is also generally the case that each type of platform still has its “optimal” uses. The Optiv series is much better than a CMM for smaller parts where the majority of features are two-dimensional whereas the Brown & Sharpe Global CMM series is better for parts that are on the larger side and have three dimensional features on multiple faces. However, with the advent of multiple sensors, it is becoming more common that the capabilities of the two types of platforms are becoming more and more similar. Since this is the case, smart users are learning to leverage the benefits of both platforms and in some instances, even use both platforms in combination on the same parts.

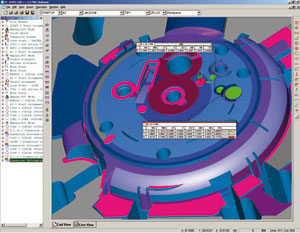

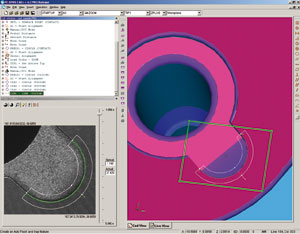

Since the majority of manufactured parts these days are designed in CAD, most inspection software like PC-DMIS is CAD integrated. The greatest advantage to CAD integration is the ease of programming, with the simplicity of point-and-click addition of features to inspect. Some software, such as PC-DMIS Vision, even allows you to click and drag to add whole groups of features at once—this is a huge time-saver on 2D parts typical for vision systems. Ironically, the rest of the world of 2D vision based inspection has been late to incorporate CAD into its software, and as a result software that has its roots in CMMs have the edge in CAD integration and utility.

CAD software

A multisensor system should have similar abilities to PC-DMIS Vision to allow programming of all the sensors from the CAD model in the same programming environment. Having to switch between different software packages to use different sensors defeats the purpose of multisensor inspection. The capability to program directly from CAD is also essential to be able to develop part programs offline. Not having to program on the machine allows it to stay productive inspecting parts, instead of acting as a programming aid. Offline programming capability allows the simulation of an inspection routine, so you can get an idea of what will happen before the part is ever placed on the machine.

A multisensor system should have similar abilities to PC-DMIS Vision to allow programming of all the sensors from the CAD model in the same programming environment. Having to switch between different software packages to use different sensors defeats the purpose of multisensor inspection. The capability to program directly from CAD is also essential to be able to develop part programs offline. Not having to program on the machine allows it to stay productive inspecting parts, instead of acting as a programming aid. Offline programming capability allows the simulation of an inspection routine, so you can get an idea of what will happen before the part is ever placed on the machine.

PC-DMIS makes it possible to use the same measurement software package for both a CMM and a vision system. This has advantages beyond the most obvious benefit of a shorter learning curve and more flexibility in the programming staff. With the PC-DMIS suite of software packages, it is possible to develop part programs offline from CAD and then use the same part program on either a vision platform or a CMM platform. Taking this idea one step further, it’s possible to design a part program that is split into two segments, with inspection starting on one type of machine and then moving the part to another—with a common inspection report as the result.

One example of a hybrid application might be turbine blades that are inspected on a traditional CMM for speed, accuracy and access to the geometric features, and then moved to a vision based machine to visually inspect the cooling holes. With PC-DMIS, these functions can be programmed offline with the same software from the same CAD model, even though the inspection functions will be performed on different physical platforms with different types of sensors.

One example of a hybrid application might be turbine blades that are inspected on a traditional CMM for speed, accuracy and access to the geometric features, and then moved to a vision based machine to visually inspect the cooling holes. With PC-DMIS, these functions can be programmed offline with the same software from the same CAD model, even though the inspection functions will be performed on different physical platforms with different types of sensors.

Since one can use multiple sensors in a single inspection routine, the choice of sensor combinations and technique can be driven by the application requirements. The best example of this is simply matching the data density required with the sensor, so taking low density data (such as touch probe) in areas where simple geometry is sufficient, and using a higher density collector (such as laser scanning) where knowledge of form is necessary, such as on a complex contour.

However, sometimes managing the tradeoffs between multiple sensor types and the desired application can take a surprising turn, as in this real-world example:

A manufacturer wishes to scan the contours of a surface with high density data (100 thousand points), at a very high accuracy (15 microns), very quickly (ten seconds). 100% inspection was desired.

Inspecting circuit boards

A vision-based system inspects a circuit board. Here’s the tradeoff:Laser Scanning: Density: Yes, Speed: Yes, Accuracy: No

Analog Scanning: Density: Yes, Accuracy: Yes, Speed: No

A multisensor machine can carry both types of sensors, but neither the individual sensors nor combining the two sensors in a single program will accomplish the goal. What’s the solution? In this case, the answer was a multisensor CMM with a large physical table, where many parts could be set up on easy load pallets, using a laser sensor as a process capability Go/No-Go gage to monitor process variability.

This allows many parts to be scanned quickly, even though the overall accuracy was not optimal. When feedback from the system indicates variability outside specified limits, the CMM automatically switches to the slower, but more accurate analog scanning probe to perform a high-precision inspection for further analysis.

In this case the combination of table size (the ability to set up hundreds of parts at once), multiple sensors, and the ability to programmatically vary the inspection process allows a multiple sensor device to be used in a novel way.