Aircraft landing gear and systems

Design, production and inspection solutions for aircraft landing gear

Ensuring critical system safety and longevity for aircraft landing gear components and assemblies.

Ready to learn how Hexagon's capabilities can empower your business?

Aircraft landing gear is an essential system that enables safety from the gate to take-off to landing. Nose and main landing gear systems include powerful actuators, structural struts and beams, complex wheels and brake systems. These are all subjected to high load, stresses and harsh environmental conditions.

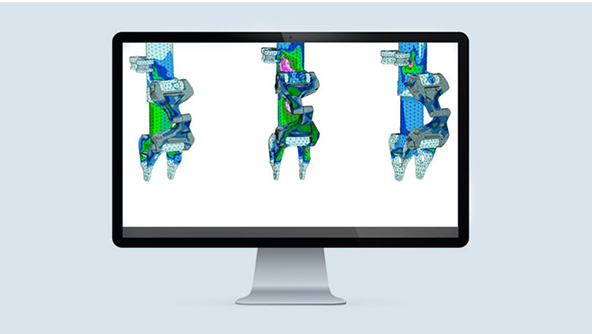

The landing gear mechanism requires complex multibody dynamics and high-load simulation on the structural parts and the wheels, tyres and brake components. Hexagon supports the needs of aircraft landing gear design with computer-aided engineering (CAE) software, including multibody dynamics and coupled simulation tools.

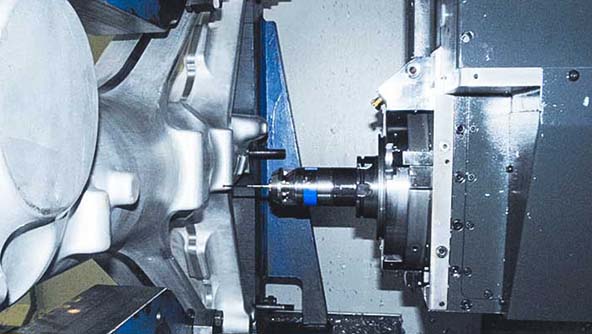

Hexagon’s production software can simulate aircraft landing gear production processes. It calculates the right amount of material to be machined and ensures tool paths are optimised. Our CAM software will generate and communicate optimised trajectories to machining centres.

When manufacturing a landing gear strut, beam, wheel or brake, these circular and cylindric parts need to be inspected both inside and out during production to ensure the materials are made correctly.

Our on-machine probing solutions support measurement of aircraft landing gear components during production. Analytics tools compile in-line metrology data to anticipate defects and make corrections during production. Hexagon’s automated non-contact metrology tools also enable process monitoring and inspection of landing gear components and assemblies near the production floor.

-

Data analytics

Structural Damage Recording and Analysis

Data analysis tools help automate and improve the crucial identification, recording and analysis of structural damage.

-

Production tools

Machine tool probing for landing gear

On-machine probing can position forged blanks and eliminate waste in the production of landing gear struts and beams.

-

Simulation and analysis

Landing gear fatigue analysis

Analysing and accurately predicting how landing gear will fatigue is a key safety concern for aerospace designers.

-

Reverse engineering

Reverse engineering of components

Using 3D scanning to reverse engineer parts makes it easier to repair, maintain and overhaul aircraft with no CAD data.

Explore capabilities

-

Manufacturing

Design and engineering phase

With Hexagon’s innovations in manufacturing technology, users can digitally simulate and optimise product design and engineering to ensure component manufacturability, production productivity and output quality.

Production phase

Maintain a digital thread through production, optimise machine tools, measure environmental variances and prevent downtime with predictive data analyses.

Inspection phase

Automate and digitalise quality measurement with our world-leading metrology hardware and software, creating a bridge between the real and digital worlds.

Digital transformation

Deploy Hexagon’s sensor software systems to transform siloed and disconnected processes into an integrated, data-driven manufacturing ecosystem that captures and creates value across the product lifecycle, enabling new business models and automating workflows to become increasingly autonomous, efficient and sustainable.