Airframe assembly

Manufacturing intelligence for airframers

Using data to help airframers achieve best-fit aircraft assembly and reduce production cycle times.

Ready to learn how Hexagon's capabilities can empower your business?

-

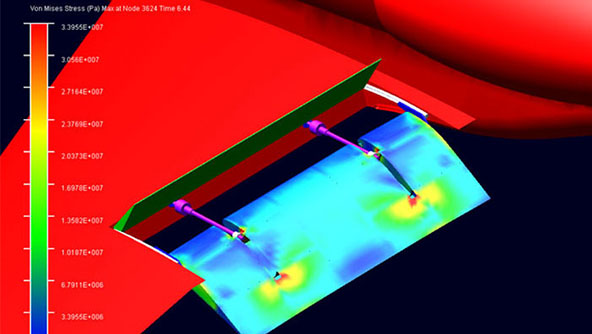

Simulation and Analysis

Virtual Testing of Aircraft Movables

Test and measure the performance of an aircraft's movable parts more quickly and cost-effectively with simulation software. -

Data Analytics

Structural Damage Recording and Analysis

Data analysis tools automate and improve the crucial identification, recording and analysis of aircraft structural damage. -

Dimensional Inspection

Frames and Stringers Measurement

Optimising the measurement of aircraft frames and stringers on the shop floor increases productivity and ensures accuracy. -

Metrology-Assisted Assembly

Control Surfaces Inclination Measurement

Accurate inclination measurement is required to calibrate and check the function of aircraft flight control surfaces. -

Production Tools

Probing for Aero-Structure Rib Machining

Precise alignment, automated measurement and on-the-machine tooling results in faster milling of aero-structure ribs. -

Reverse Engineering

Reverse Engineering of Aero Components

Using 3D scanning to reverse engineer parts makes it easier to repair, maintain and overhaul aircraft with no CAD data.

Explore capabilities

-

Manufacturing

Design and engineering phase

With Hexagon’s innovations in manufacturing technology, users can digitally simulate and optimise product design and engineering to ensure component manufacturability, production productivity and output quality.

Production phase

Maintain a digital thread through production, optimise machine tools, measure environmental variances and prevent downtime with predictive data analyses.

Digital transformation

Deploy Hexagon’s sensor software systems to transform siloed and disconnected processes into an integrated, data-driven manufacturing ecosystem that captures and creates value across the product lifecycle, enabling new business models and automating workflows to become increasingly autonomous, efficient and sustainable.