Electric vehicle drivetrains

Ensuring effective power transmission at high torque through manufacturing solutions designed for the requirements of electric vehicle drivetrain systems

Contact us

Compared to the development process for traditional combustion engine vehicles, eMobility is driving substantial change in the way manufacturers approach drivetrain design. Where previously 6-speed manual or 8-speed automatic transmissions were standard in the automotive world, state-of the-art electric vehicles use different kinds of automatic transmissions such as 2-stage spur gear drives, integrated stepped planetary gear drives or continuously variable transmissions (CVT) – also known as shiftless transmission – to operate at optimum efficiency.

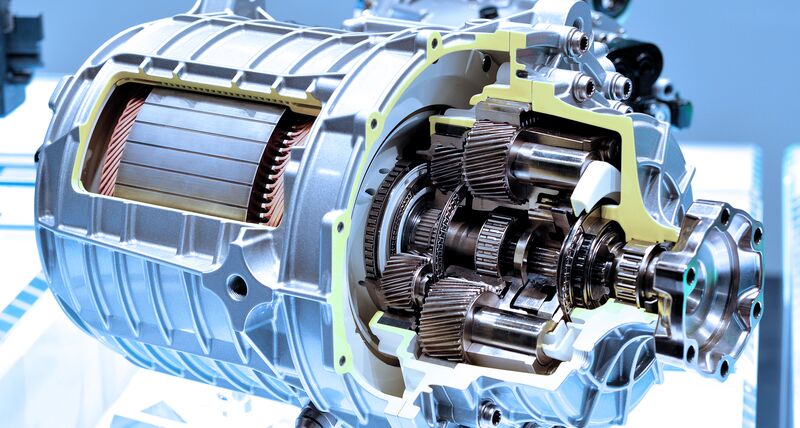

Often, electric motors, power electronics and drivetrains share a single housing, reducing the overall number of components in the powertrain and lowering the overall weight of the system. In battery electric vehicles (BEVs), this integrated unit may directly power a combined electric axle drive. In hybrid vehicles, various transmission configurations are possible depending on how the manufacturer intends the electric motor and combustion engine to interact with each other.

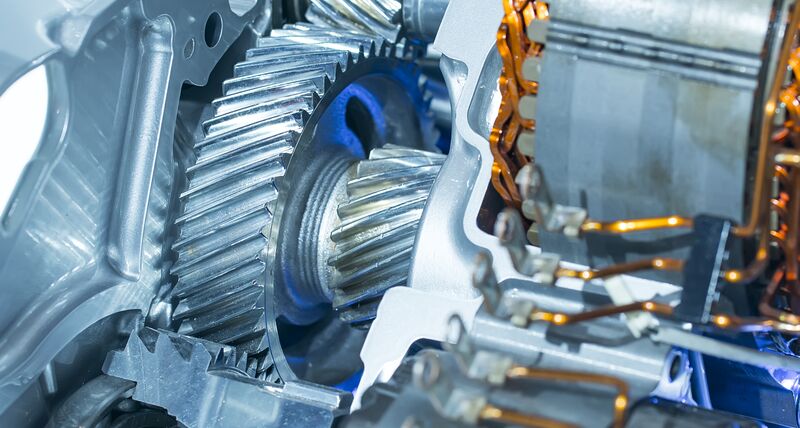

While many operating principles for electric vehicle drivetrains differ from their counterparts in combustion engine vehicles, on the component level there are actually many similarities in the design and manufacturing processes required. Key components like straight gears, helical gears and housings are common to both types of drivetrain. The main challenges in specialising such components for electric vehicle drivetrains are to deal with the higher torque and speed of rotations that can be realised with electric motors. The tolerances involved in the precision manufacturing of transmission components like straight and helical gears or planetary gear drive systems are typically tighter for electric vehicle components. The surface finish of gears also gains new importance as the noise emission of the drivetrain is critical in electric vehicles due to the silent electric motor.

Hexagon has considerable experience in the development of powertrain components in both the automotive and aerospace sectors and is well placed to support manufacturers throughout the development of electric vehicle drivetrains. Our simulation solutions enable manufacturers to optimise gear and bearing design, model durability, simulate lubrication efficiency and assess noise emissions before vehicles go into development. Our production software solutions both validate production processes and ensure precision manufacturer of tight tolerance transmission parts, while our ultra-high accuracy measurement systems are specified for inspection and quality assurance of critical parts like gears, shafts and casings.

Often, electric motors, power electronics and drivetrains share a single housing, reducing the overall number of components in the powertrain and lowering the overall weight of the system. In battery electric vehicles (BEVs), this integrated unit may directly power a combined electric axle drive. In hybrid vehicles, various transmission configurations are possible depending on how the manufacturer intends the electric motor and combustion engine to interact with each other.

While many operating principles for electric vehicle drivetrains differ from their counterparts in combustion engine vehicles, on the component level there are actually many similarities in the design and manufacturing processes required. Key components like straight gears, helical gears and housings are common to both types of drivetrain. The main challenges in specialising such components for electric vehicle drivetrains are to deal with the higher torque and speed of rotations that can be realised with electric motors. The tolerances involved in the precision manufacturing of transmission components like straight and helical gears or planetary gear drive systems are typically tighter for electric vehicle components. The surface finish of gears also gains new importance as the noise emission of the drivetrain is critical in electric vehicles due to the silent electric motor.

Hexagon has considerable experience in the development of powertrain components in both the automotive and aerospace sectors and is well placed to support manufacturers throughout the development of electric vehicle drivetrains. Our simulation solutions enable manufacturers to optimise gear and bearing design, model durability, simulate lubrication efficiency and assess noise emissions before vehicles go into development. Our production software solutions both validate production processes and ensure precision manufacturer of tight tolerance transmission parts, while our ultra-high accuracy measurement systems are specified for inspection and quality assurance of critical parts like gears, shafts and casings.

-

Dimensional inspection

-

Simulation and analysis