Composite materials in aerospace

The use of CFRP materials in aircraft manufacturing is taking off.

Contact us

Aerospace is one of the key sectors that has been driving the growth in use of composite materials in recent years, with large manufacturers attracted by the potential for significant reductions in fuel usage and carbon dioxide emissions.

Leading manufacturer Airbus has been a forerunner when it comes to adding composites to their range of aircraft. Some 70 percent of the materials used to make every Airbus A220 are advanced materials, with 46 percent being composite materials and 24 percent aluminium-lithium.

The design of Airbus’ long-haul A350 XWB aircraft places even more trust in composites; it’s 53 percent carbon-composite construction results in a 25 reduction in operating costs, fuel burn and CO2 emissions.

Economy and sustainability aren’t the only areas in which composites have delivered benefits to Airbus and their customers. The carbon composites used in the Airbus A350 XWB also enable a more spacious fuselage design as well as the highest possible air quality, with optimised cabin altitude and humidity levels for improved passenger comfort.

Elsewhere in Airbus’ aircraft line-up is the A400M, whose wings are primarily constructed from a carbon-fibre reinforced plastic, and whose eight-bladed Ratier-Figeac scimitar propellers are made from a woven carbon-fibre material.

And Airbus isn’t the only aerospace manufacturer enjoying success with composite materials. Since increasing the level of composites used in their aircraft, Bombardier claims to have achieved a 15 percent reduction in seat-mile cost, a 20 percent drop in fuel burn and a significant CO2 emissions advantage.

Composites are even set for orbit, with leading space industry innovator SpaceX having designed and constructed the world’s largest carbon-fibre composite fuel tank for their Big Falcon Rocket (BFR) interplanetary spaceship.

Source: Airbus

Leading manufacturer Airbus has been a forerunner when it comes to adding composites to their range of aircraft. Some 70 percent of the materials used to make every Airbus A220 are advanced materials, with 46 percent being composite materials and 24 percent aluminium-lithium.

The design of Airbus’ long-haul A350 XWB aircraft places even more trust in composites; it’s 53 percent carbon-composite construction results in a 25 reduction in operating costs, fuel burn and CO2 emissions.

Economy and sustainability aren’t the only areas in which composites have delivered benefits to Airbus and their customers. The carbon composites used in the Airbus A350 XWB also enable a more spacious fuselage design as well as the highest possible air quality, with optimised cabin altitude and humidity levels for improved passenger comfort.

Elsewhere in Airbus’ aircraft line-up is the A400M, whose wings are primarily constructed from a carbon-fibre reinforced plastic, and whose eight-bladed Ratier-Figeac scimitar propellers are made from a woven carbon-fibre material.

And Airbus isn’t the only aerospace manufacturer enjoying success with composite materials. Since increasing the level of composites used in their aircraft, Bombardier claims to have achieved a 15 percent reduction in seat-mile cost, a 20 percent drop in fuel burn and a significant CO2 emissions advantage.

Composites are even set for orbit, with leading space industry innovator SpaceX having designed and constructed the world’s largest carbon-fibre composite fuel tank for their Big Falcon Rocket (BFR) interplanetary spaceship.

Source: Airbus

Our solutions

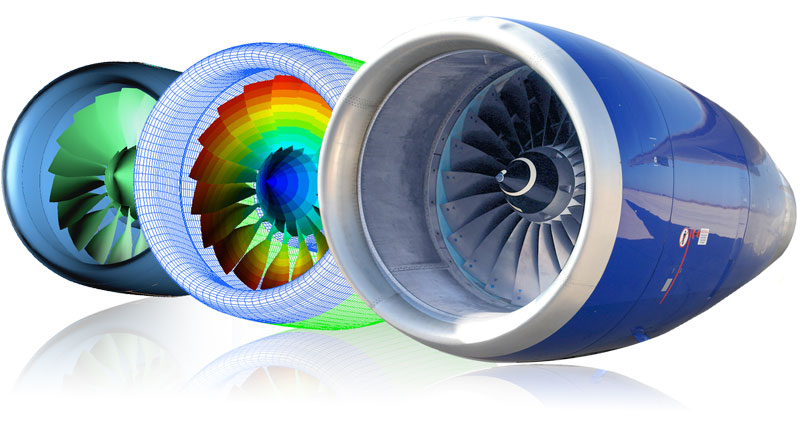

Explore Hexagon solutions for machine tool probing for aligning turbine wheels.

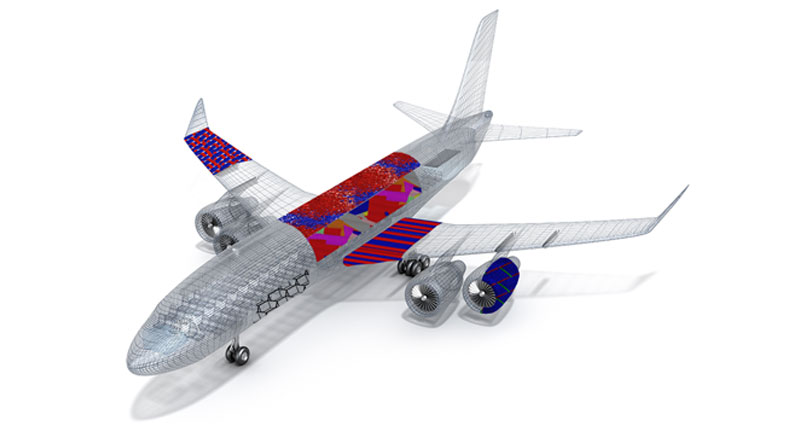

Materials lifecycle management for aerospace

Aircraft manufacturers can improve the use and traceability of materials, as well as product design, by capturing, managing and sharing data about materials from within integrated processes.

Composite aircraft component design

Simulation software can be used to reduce development cycles by virtually testing CFRP components for the aerospace industry.

Carbon fibre ply simulation for aerospace parts

The complexity and cost of creating CFRP aircraft components mean manufacturers benefit from analysing and simulating the impact of manufacturing defects on part performance.