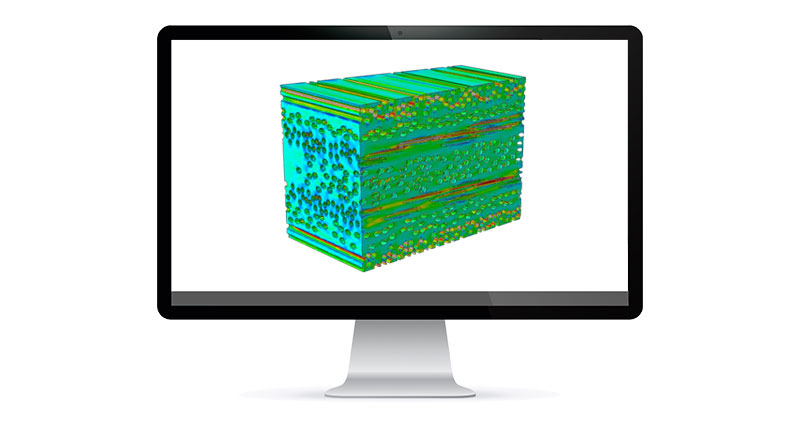

Carbon fibre ply simulation for aerospace parts

Analysing the properties of carbon fibre reinforced polymer (cfrp) parts to understand impact on mechanical performance

Contact us

Carbon fibre reinforced polymer (CFRP) parts play an important role in reducing the structural weight of an aircraft. They are manufactured using automated fibre placement (AFP) machines, which enable aerospace companies to produce CFRP parts such as tail cones or wing skin panels relatively quickly.

When producing large aircraft structural parts, defects can arise during the AFP manufacturing process. These may affect the mechanical properties of the final CFRP composite part. When placing composite strips on a double curved surface, for example, robots might have to cut tows and restart, resulting in misalignment and gaps in the finished material.

Given the structural importance of CFRP parts in aircraft today, aerospace manufacturers need to be able to analyse and understand the impact of any defects that arise. Hexagon’s computer-aided engineering (CAE) software enables manufacturers to do that by pulling data directly from the AFP control software to conduct a structural analysis of the composite using a micromechanical model. This helps manufacturers to ensure quality by automatically simulating and assessing the final part’s mechanical properties and performance.