Highest precision for the production of high-tech parts and modules

Gantry-style CMM technology comes together with the PC-DMIS metrology software platform to deliver excellent accuracy results and continue a long-standing history of cooperation

Contact us

DELTA SLANT gantry CMM at VDL ETG in Switzerland

VDL Enabling Technologies Group (ETG) Switzerland AG has been relying on Hexagon’s coordinate measuring machines and software for several years. As they continue to assert themselves successfully in the high-tech market, the business is investing sustainably in advanced products, which is why they have once again opted for a system from Hexagon – the DELTA SLANT.

The production site VDL ETG Switzerland AG, in Trübbach, belongs to the globally active VDL Group, with headquarters in Eindhoven, Netherlands. With a wide range of products, VDL ETG Switzerland AG has distinguished itself in various market segments and as a strong partner for different customers.

Initially, the focus of VDL ETG Switzerland AG was on contract manufacturing. Gradually the company has developed into a module supplier, supplying OEM companies that play a leading role in the development of high-tech manufacturing systems. These production systems are used in the semiconductor and vacuum industries for the manufacture of a wide range of products.

Initially, the focus of VDL ETG Switzerland AG was on contract manufacturing. Gradually the company has developed into a module supplier, supplying OEM companies that play a leading role in the development of high-tech manufacturing systems. These production systems are used in the semiconductor and vacuum industries for the manufacture of a wide range of products.The foundation of the company is the production of components and modules that are used for tomorrow’s technologies. Over the years it has specialised in vacuum soldering among other core competences, mainly for the analytical market and the semiconductor industry. Customer requirements are as diverse as the variety of parts, and the company’s existing expertise is combined with the necessary measuring equipment to meet customer component requirements. As a result, VDL ETG Switzerland AG can produce parts in different sizes and then also evaluate them to an accuracy of as little as 5 microns.

Further investment in Hexagon’s

technologies

A total of 8 Hexagon machines are in use at the VDL ETG Switzerland AG production facility in Trübbach. Some of them have been in operation for more than a decade and are functioning perfectly. The most recent investment was a DELTA SLANT model, which belongs to Hexagon’s series of gantry CMMs. Thanks to its excellent mechanical design, it is particularly suitable for the high-precision inspection of large-volume components.

A total of 8 Hexagon machines are in use at the VDL ETG Switzerland AG production facility in Trübbach. Some of them have been in operation for more than a decade and are functioning perfectly. The most recent investment was a DELTA SLANT model, which belongs to Hexagon’s series of gantry CMMs. Thanks to its excellent mechanical design, it is particularly suitable for the high-precision inspection of large-volume components. “The repeatability and accuracy to nominal value are impressive,” explains Silvio Steinbacher, long-standing Metrology Team Leader at VDL ETG Switzerland AG. “Our demanding parts can be completely measured.”

VDL ETG Switzerland AG purchase decision

The large production machines at the in-house production site meant that a larger measuring machine was also needed in order to continue to meet the high demands – customers expect accurate and high-quality results. The long-term cooperation with Hexagon and the available products, product design and software were decisive for the purchase of the DELTA SLANT CMM. By investing in several Hexagon machines, VDL ETG Switzerland AG benefits from more flexibility and efficiency. This means that product adaptations and individual customer requirements can be better accounted for. The Q-DAS and PC-DMIS software brings the advantage of being able to coordinate all needs, as well as providing valuable statistics that can be used to guarantee high quality standards.

The large production machines at the in-house production site meant that a larger measuring machine was also needed in order to continue to meet the high demands – customers expect accurate and high-quality results. The long-term cooperation with Hexagon and the available products, product design and software were decisive for the purchase of the DELTA SLANT CMM. By investing in several Hexagon machines, VDL ETG Switzerland AG benefits from more flexibility and efficiency. This means that product adaptations and individual customer requirements can be better accounted for. The Q-DAS and PC-DMIS software brings the advantage of being able to coordinate all needs, as well as providing valuable statistics that can be used to guarantee high quality standards. Successful commissioning in a challenging environment

The analysis phase of the purchase process was used to identify possible risks and work out solutions for a smooth commissioning, and the VDL ETG Switzerland AG and Hexagon teams were in close contact for several weeks. According to Silvio Steinbacher, it was important to have a contact person on site during the risk analysis in order to solve any problems directly.

The biggest challenge was the location of the new measuring room, which had to be built as close as possible to the existing measuring room and production area. With some adjustments to the standard concept, a solution could be found for the vibrations caused by production. Another difficulty was the height of the machine. The primary goal was to meet the expectations for very high measuring accuracy without having to take further measures such as lowering the floor or opening the roof. The high requirements were met, and Silvio Steinbacher was very satisfied with the result.

Another difficulty was the height of the machine. The primary goal was to meet the expectations for very high measuring accuracy without having to take further measures such as lowering the floor or opening the roof. The high requirements were met, and Silvio Steinbacher was very satisfied with the result.Thanks to the many years of experience of Hexagon’s experts, the standard specifications were even exceeded – thanks to the air conditioning of the room, stabilisation measures and other optimisations, the measured values are above the requirements guaranteed in the standard data sheet. The project was completely realised within one year.

Reliable quality software

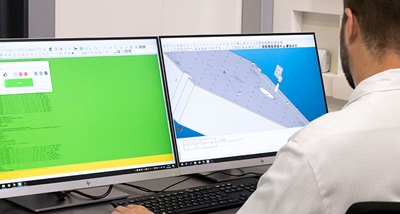

The decisive argument for further investment in Hexagon CMM technology was the PC-DMIS software. “Existing programs can be transferred to the machine practically1:1,” explains Steinbacher. “This is indeed the case – with the smallest technical adjustments, the existing system runs on the new machine. Our PC-DMIS-experienced staff can handle it without any problems and do not have to familiarise themselves with a complex new system. Our young employees in particular are very instressed by the versatility of this software.”

“The repeatability and accuracy to nominal are sensational. Our demanding parts can be measured completely.”

Silvio Steinbacher

Metrology Team Leader

VDL ETG Switzerland AG