MSC Apex Generative Design

최고의 적층 제조를 위한 스마트 제너레이티브 디자인

Ready to learn more?

Innovative technology for innovative designs

MSC Apex Generative Design's innovative approach has been proven in practice

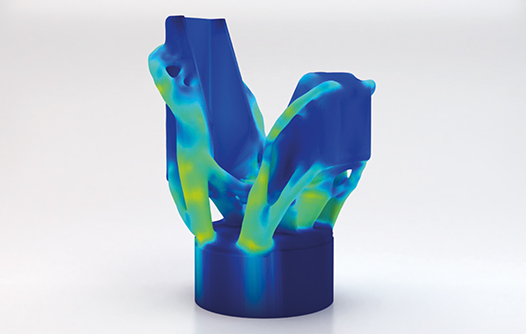

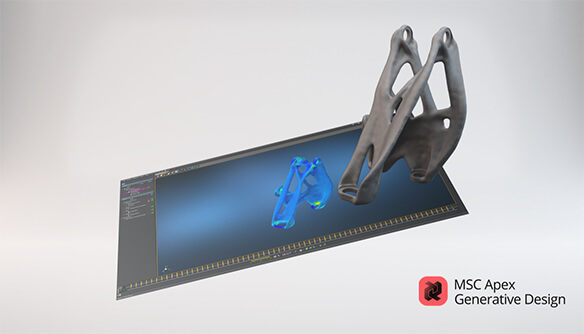

It is based on Finite Element Analysis but, unlike traditional methods, does not use a density field, rather utilizes a very fine mesh with well-defined elements. This enables the algorithm to directly evaluate the occurring stresses, as well as reliably derive distinct geometries that are truly unimaginable by human mind.

Design for Additive Manufacturing (DfAM) without Expert Knowledge

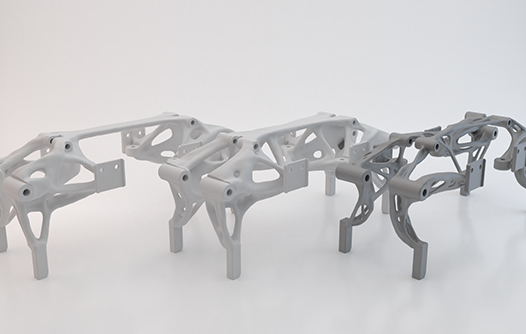

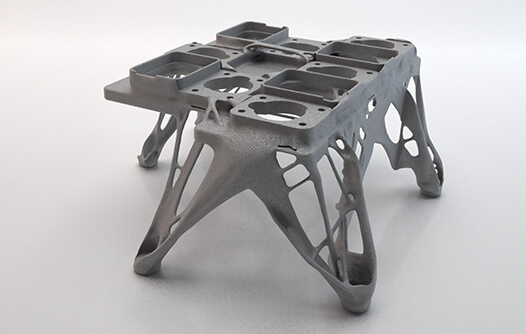

MSC Apex Generative Design is designed specifically to generate the detailed and highly complex structures that only additive processes can manufacture. The optimised designs exhibit perfect transitions between structure elements such as struts and shells as well as they contain usually self-supporting structures that ensure the results can be sent straight to print.

MSC Apex Generative Design at a glance

- Simplicity - No expert knowledge required for conducting optimisations through a high user-focused software design.

- Automated Design - Almost automatically generate multiple smoothed design candidates that all satisfy the design criteria while minimizing the weight.

- Import and Validation - Import existing geometries or mesh, find optimized design candidates, and perform design validation - all inside a single CAE environment.

- Direct Output - Export geometry that can be directly manufactured and used immediately without manual re-work.

- One Process - Import the resulting geometries in Simufact Additive or Digimat AM to achieve cost-efficient first-time-right result for every part.

Case study: Lightweight bracket

Case study: Optimised wheel carrier

Case study: Stiff motor mount

Learn more about MSC Apex Generative Design

Collaterals

Brochure

MSC Apex Generative Design

Infographic

Generative Design and Metal 3D printing

Flyer

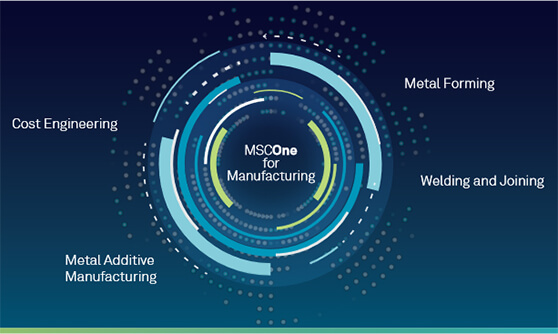

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

On-Demand Webinars

Webinar

Spice your engineering workflow with generative design

Webinar

How Apex Generative Design eases your engineering life

Training Series

Boost your engineering productivity

-

"With the ease of use and optimization speed, we see MSC Apex Generative Design as a game changer for EDAG. We can now generate even more lightweight designs in a fraction of time. This efficiency really pushes our product development."Lucas EpperleinEDAGCase Study: Satellite Bracket

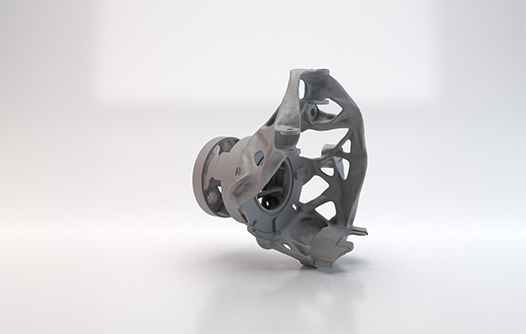

Lightweight construction is particularly important in satellite design because every extra kilogram generates high costs for transportation into space. If weight can be saved, the valuable payload of the launch vehicle or satellite can be used for further applications and added value can be created.

This was exactly the aim of the project between the space company Tesat-Spacecom GmbH & Co. KG, the machine manufacturer Trumpf and MSC Software / Simufact Generative Design specialists. The pictured mountings of drives for regulating microwave filters are to be used in the German communications satellite Heinrich Hertz, which is to test the space capability of new communications technologies. For this application, the weight of the mount needed to be reduced.

MSC Apex Generative Design was used to achieve this.

Lightweight Design on a new Level

A new, highly complex design was created by applying generative design, which enables maximum lightweight construction and is perfectly adapted and designed to the operational requirements. The result for the TESAT mount is impressive: 55% weight saving for a component designed for space technology. Instead of 164 grams, the mounting weighs only 75 grams. In addition, the innovative, stress-oriented optimization has further increased the stiffness of the component. The homogeneous stress distribution generated by MSC Apex Generative Design enables excellent stiffness and robustness with maximum weight reduction at the same time.

A perfect fit: Generative Design and 3D printing

"Today, additive manufacturing enables us to produce digitally generated and optimized geometries cost-efficiently. This offers enormous potential for lightweight construction, especially in space technology, but also in many other areas. In the future, generative design will play a key role in the uncomplicated and efficient use of this potential," commented Dr. Thomas Reiher, Director Generative Design at Simufact Engineering.

This new type of complex geometry can now only be produced with additive manufacturing. Trumpf took on this task with the TruPrint 3000 3D printer. The Heinrich Hertz satellite mission is carried out by DLR Space Management on behalf of the Federal Ministry of Economics and Energy and with the participation of the Federal Ministry of Defense.

-

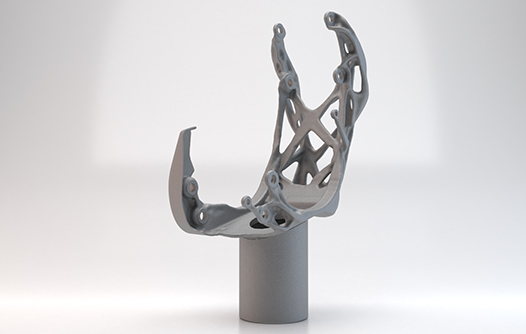

Case Study: Formula Student: Superior Design of a Wheel Carrier for maximum Performance

Every year a team of young students from the UPBracing Team develops a FormulaStudent racing car to compete in international competitions. Two factors are essential for a successful racing car: light weight and strong components. In addition to the races in which drivers and racing cars prove their performance, there is also an extra rating for the lightweight construction of the racing car. Due to its fourfold use, the wheel carrier is ideal for saving weight while meeting high load-bearing requirements.

Conventional design for milling, due to the very complex shape the parts weighs 515g but produces 15.5kg aluminum waste

Optimized lightweight design in only 8 hours

Smart Generative Design for tailored 3D Printing Structures

In previous years, the teams had tried to design light weight wheel carriers with complex milling designs. The wheel carrier in 2012 with a traditional, already complex, milling design weighed 515g. It was milled from a 16 kg block of material thus producing 15.5 kg of aluminum waste. For the 2018 season, MSC Apex Generative Design technology was applied to create an optimal lightweight design. Design and non-design areas were defined in the model design and the complex load cases were added. The mesh was then automatically generated and optimized. The algorithm generated the finished smoothed result on a workstation with the high-end NVIDIA Tesla P100 graphic card in 6 hours (which would take approximately 14 hours with a solid workstation GPU NVIDIA QUADRO P5000). The result was single wheel carrier of with a weigh of 266g - a reduction of 48% compared to the 2012 equivalent. There was also no significant waste of material because the part was produced by additive manufacturing. This contributed considerably to the overall weight reduction of the race car and gained a lot of attention and a very good rating within the design report, a special category in the overall competition.

-

Case Study: Driving Lightweight to the Maximum: Redesign of an Aerospace Bracket

A popular example for testing the optimization quality of different algorithms is the "GE Jet Engine Bracket". This bracket of an aircraft turbine was published on the GrabCAD website by General Electric in 2013 as a design challenge for additive manufacturing. The challenge was to redesign the very simple component design using any method, and to develop a component that was as light as possible while taking the given boundary conditions into account. The Challenge attracted a great deal of attention and is still frequently used today to demonstrate the strengths of new algorithms.

Three different designs for the Jet Engine Bracket Optimization by MSC Apex Generative Design created in very short timeChoosing the most promising Design from various Variants

The same component with the same loads was calculated by MSC Apex Generative Design, with the results shown above. They were each calculated on a CAD workstation with two Nvidia P5000 graphics cards in less than an hour. The result reaches from an optimally-shaped, thin, multi-curved shell with thin additional struts for the transmission of the highest loads to a strut only design. Especially the shell design is very stable, particularly light and easy to produce with additive processes because hardly any support structure is required. It can only be achieved with a particularly high calculation resolution as MSC Apex Generative Design is capable of calculating while still being super fast. The automated generative design from MSC Apex Generative Design shown here is even lighter and has lower stress than other solutions. A weight of only about 140g could be achieved with a maximum stress of 680 MPa (target stress 700MPa). -

Case Studies

- Northrop Grumman Mission Systems

- Satellite technology: Lightweight construction...

- Race sports: Catch the highest performance...

- Marshall Aerospace and Defence Group

- DOCAN Co.

- Embraer develops aircraft parts & assemblies 3x faster

- Enabling reliable aircraft structures...

- Design validation for efficient Additive Manufacturing

- Generating competitive 3D printing designs...

- Engineering ingenuity driven by Generative Design

- Generative design helps e-Bike manufacturer

- Framework Construction: Static simulation...

- TLG Aerospace, LLC: MSC Apex helps...

- Boiler Structure: Static Simulation...

- Joby Aviation

- DEMA SpA: MSC Apex reduces time to analyze...

- Haver & Boecker Niagara

- Simusolve Australia: Vehicle assembly in 100 hours?

- Optimizing semiconductor production hardware

- Tyvak engineers use MSC Apex to reduce satellite...

- Honda Motor Company

- Kú Cycle

- Accelerate product development of complex hood hinges

- Lightweight additive technology for increased efficiency in packing industry

- Easy handling of difficult tasks..

-

Collateral

-

e-bookDesign for AM

-

White paperThe 7 habits of highly effective generative design

-

White paperHow to enhance product development efficiency

-

Application reportLoads simulation for aircraft structure

-

Application reportAircraft acoustic simulation analysis

-

Application reportAero engine multibody dynamics simulation

-

Application reportAero engine blade thermo-structural design

-

Application reportHard Landing Stress Simulation

-

Application reportLanding gear fatigue life prediction analysis

-

BrochureAdditive manufacturing 2020

-

BrochureDesign & engineering simulation solutions

-

BrochureMSC Apex Generative Design

-

-

On-Demand Webinars

-

WebinarIntroduction to MSC Apex Python Scripting & Utilities

-

WebinarMSC Apex Generative Design 2020 Release Webinar

-

WebinarMSC Apex Generative Design 2020 FP1 Release Webinar

-

WebinarHow Generative Design eases your daily engineering life

-

WebinarHxGN Virtual Manufacturing Suite Introduction

-

WebinarPredicting fatigue lifetimes

-

WebinarPowering your engineering workflow

-