Additive manufacturing technologies

Industrialise additive manufacturing (AM) for scalable, repeatable and reliable AM operations.

Ready to learn more?

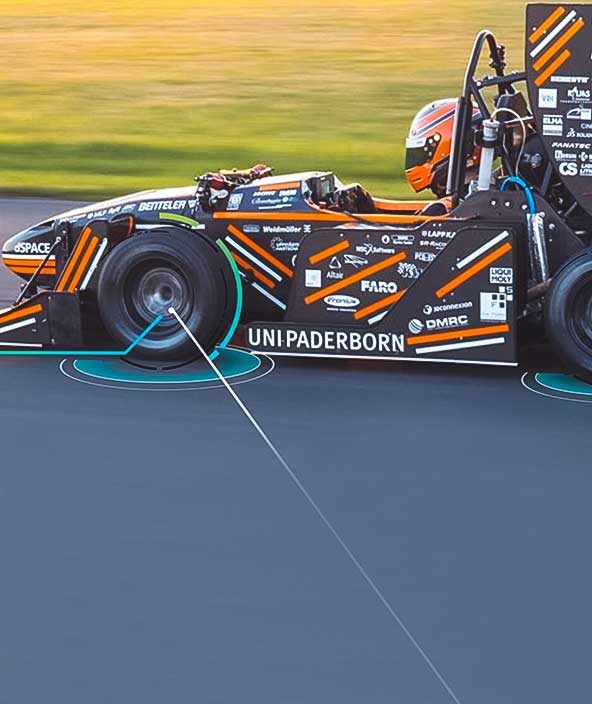

Additive manufacturing (AM), or 3D printing, is leaving the niche of prototyping and standing at the edge of industrialisation. Hexagon’s AM solutions enable manufacturers to scale and optimise their end-to-end AM process from design and material selection to production and quality assurance.

Industrialising AM

-

AM end-to-end

-

Design for AM

-

Materials for AM

-

Quality in AM

-

Manufacturing

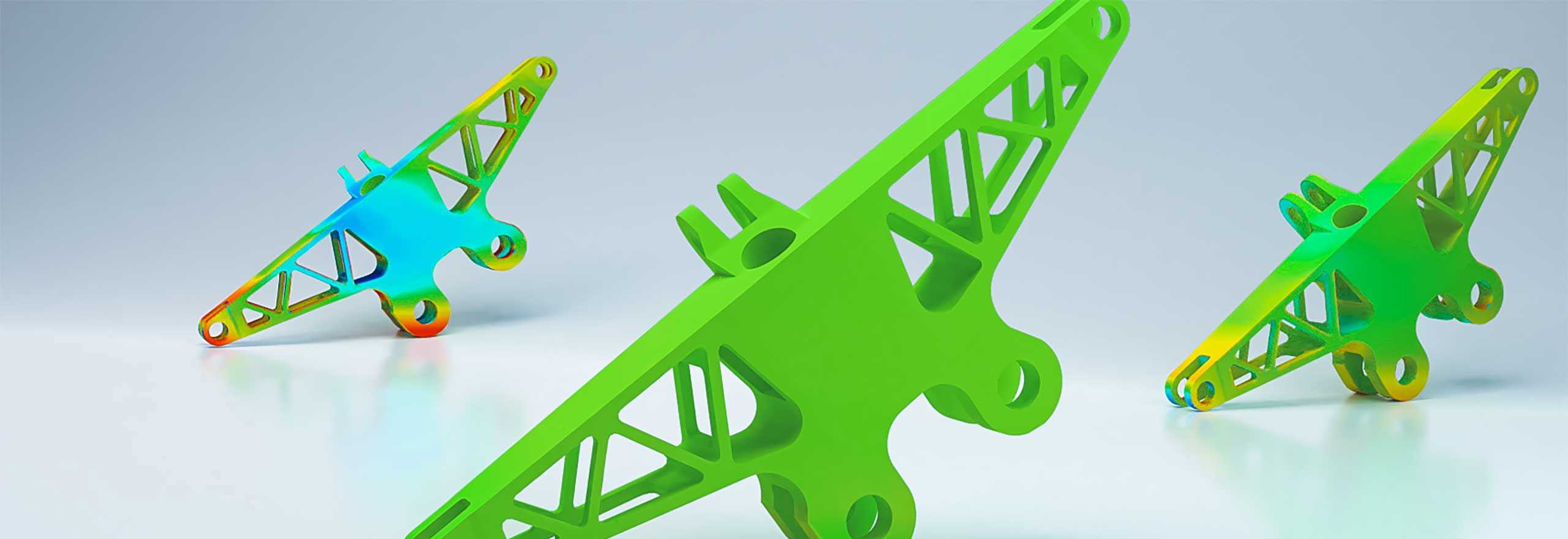

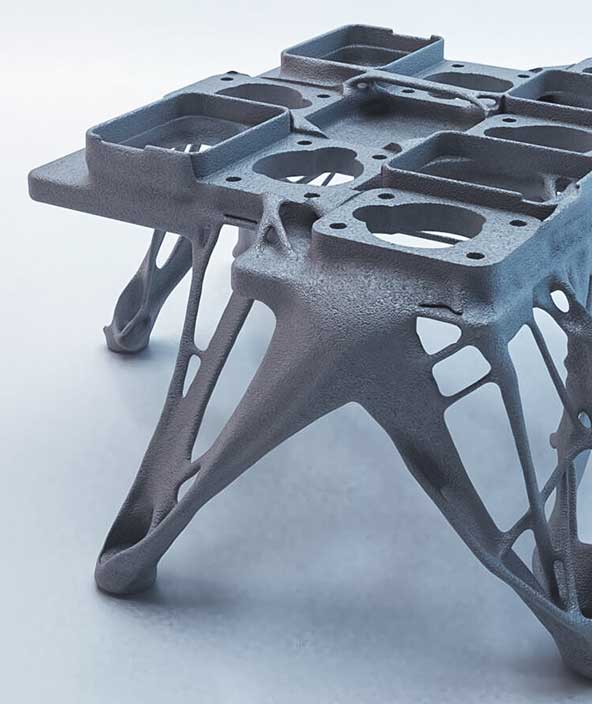

Additive manufacturing (AM), or 3D printing, creates 3D components by adding layers of material based on a digital model. Compared to subtractive manufacturing techniques that produce a final product by cutting material away from a block, additive manufacturing technologies have the potential to reduce waste and support lightweighting. AM provides enormous design freedom, allowing engineers to explore more freeform, organic designs and identify the optimal approach.

Although established in applications such as prototyping, additive manufacturing has proved challenging to scale up and realise its considerable potential in volume applications. Hexagon’s solutions are helping to industrialise AM by enabling end-to-end process digitalisation as well as providing dedicated tools to cover:

- Design for additive manufacturing (DfAM)

- Material development and selection for additive manufacturing

- Additive manufacturing operations

- Quality assurance for additive manufacturing

Design for additive manufacturing solutions

Design for additive manufacturing (DfAM) is gaining more and more importance with the transition of 3D printing from prototyping to end-use part production.

Due to the huge design freedom additive manufacturing technologies provide, industry is shifting to not only use AM as a flexible prototyping technology for classic designs, but also to leverage AM potential with completely new designs.

While the classic and quite restrictive design for manufacturing (DfM) approach is focused on manufacturable designs, the DfAM concept comprises both specific production guidelines and geometric freedom. As traditional design methods and tools do not provide both, modern DfAM tools are required.

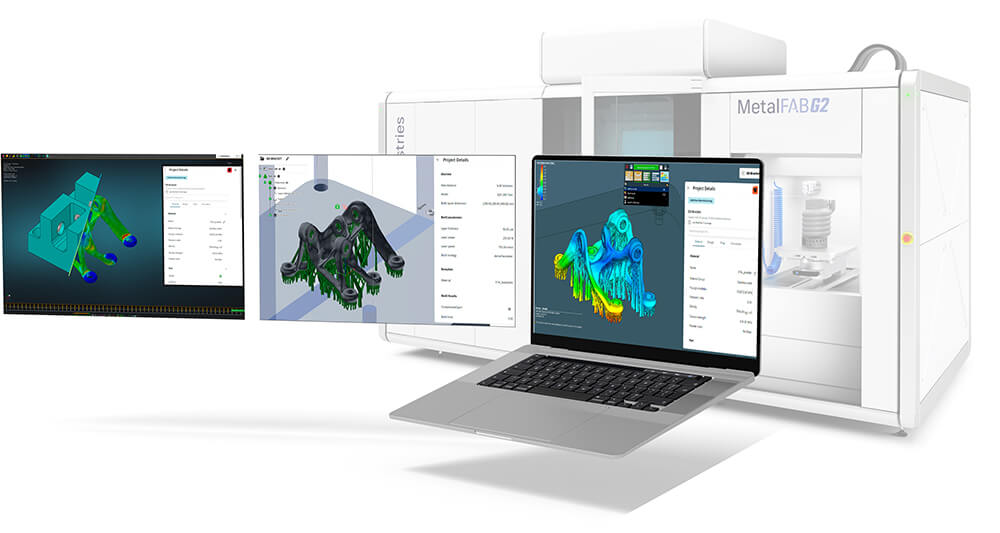

Hexagon’s DfAM capabilities include:

- Generative design

- CAE validation

- Build simulation including post-processing and optimisation

- Build preparation

Materials for additive manufacturing solutions

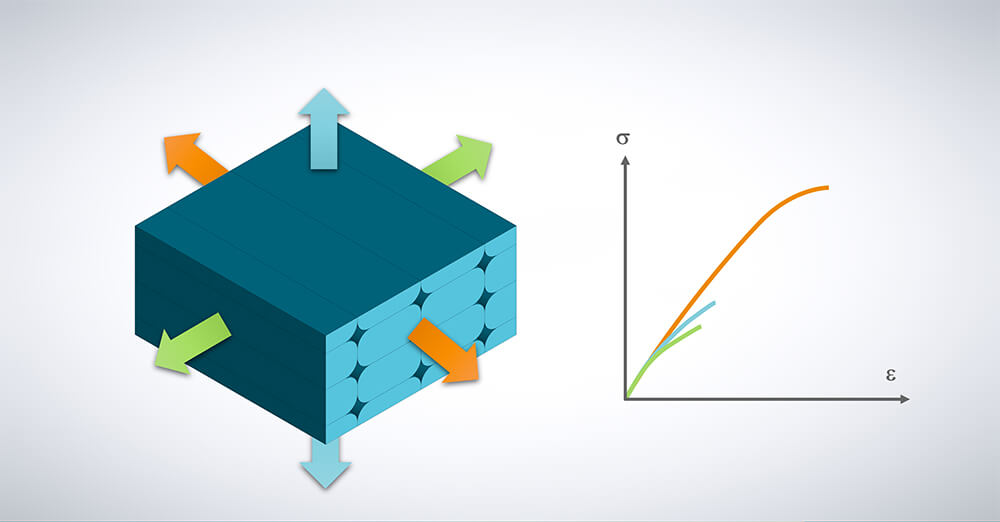

Materials play a crucial role in all manufacturing processes, and additive manufacturing is no exception. Material selection and the need for appropriate materials, is critical. It affects all subsequent processes in the AM value chain – from design to production and post-processing, and of course cost factors of the manufacturing process itself, which finally determine the cost per part.

Materials requirements for AM include the ability to produce the feedstock in a form amendable to the specific AM process, suitable processing of the material by AM, ability to be sufficiently post-processed to enhance geometry and properties, and manifestation of necessary performance characteristics in service.

Hexagon’s materials for AM capabilities include:

- Materials selection

- Materials development

- Part performance

- Integrated computational materials engineering (ICME)

- Material lifecycle management

Quality for additive manufacturing solutions

With the move to adopt additive manufacturing for larger-scale production, consistent and repeatable final part quality has become a basic requirement. The rules of quality need to be applied in the same way as for production parts made by more traditional methods. There are as many or even more areas of focus where technology needs to be applied to ensure quality standards are met.

Hexagon’s quality assurance for AM capabilities include:

- Optical scanning

- Laser scanning

- In-line monitoring

- Roughness measurement

- In-situ / in-process monitoring

- In-line and near-line inspection

- Reverse engineering as a near-line inspection process

Additive manufacturing operations solutions

To enable scaled-up production, the digital thread typically connects with manufacturing executions systems (MES) to manage the production process from order intake to part and process documentation.

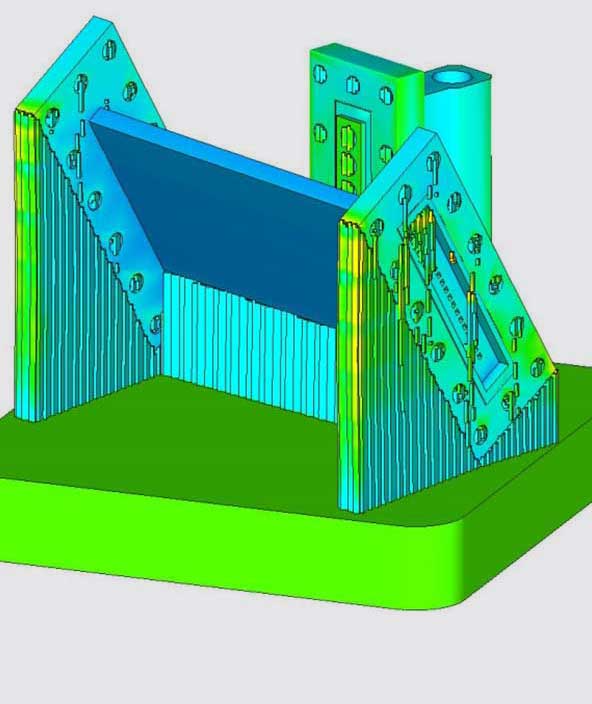

In AM, printed parts always need some post-processing and finishing, such as baseplate cutting, support removal, heat treatment, shot-peening and/or machining. A special focus must be put on the workflow after 3D printing which is – as of today – still characterised by manual non-automated work steps. Post-processing becomes the focal point for speeding up the complete end-to-end process through better connected solutions and higher-grade automation, reducing the cost factor.

Hexagon’s digital additive manufacturing operations solutions help support:

- Production management (MES)

- CAD/CAM for AM parts

- Hybrid manufacturing

- Post-processing automation

Explore

$ProductName

$SustainabilityImpactLabel

$SustainabilityCTABandHeadingLabel

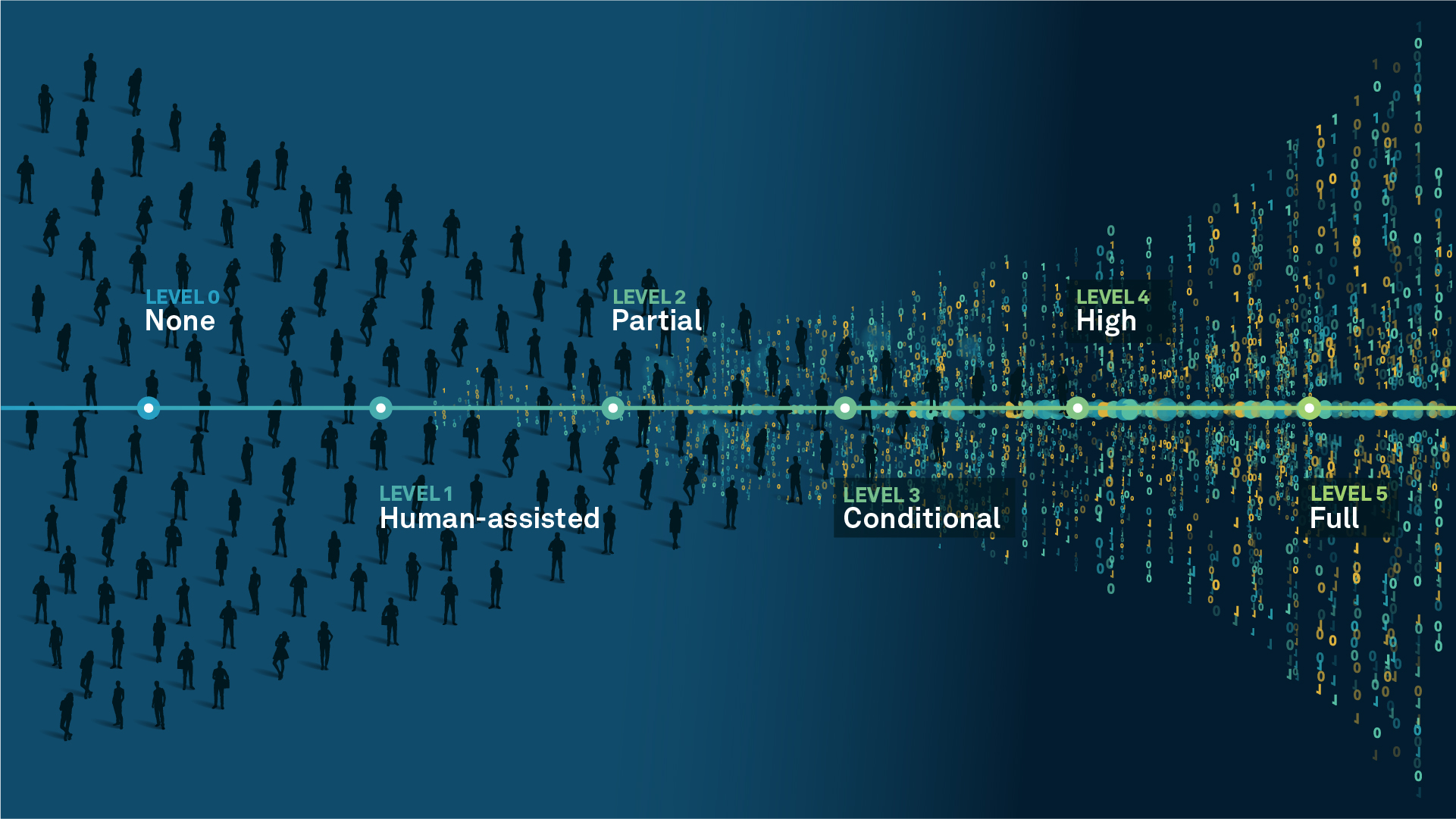

We’re climbing the automation curve

Our transition to Intelligent automation is accelerating. Ultimately, our innovations will give rise to new technologies and applications - many of which we’ve yet to imagine. Today, every Hexagon solution is mapped and tagged according to its level of automation, so customers can clearly track our progress towards the freedom of autonomy.

Human-driven

All tasks completed by human labour; no data is leveraged across the operation.

Human-assisted

Labour is primarily conducted by a human workforce. Some functions have been automated to simplify control.

Partial automation

Some tasks are automated for short periods of time, accompanied by occasional human intervention.

Conditional automation

Human workforce is used for intervention as autonomous operations begin to increase productivity.

Highly autonomous

Autonomous systems complete required tasks within specific bounds, unleashing data and building smart digital realities.

Full autonomy

A smart digital reality™ enables autonomous systems to complete all tasks without human intervention.

Land

Products that make an environmental impact in forest monitoring, material reusability, farming or water usage.

Air

Products that make an environmental impact in renewable energy, noise pollution elimination and e-mobility.

Water

Products that make an environmental impact in saving our oceans, reducing pollution and increasing access to clean water.