Hexagon’s solutions for the autonomous mobility ecosystem are solving one of the most promising and difficult technological challenges in history — the autonomous movement of people and goods.

While most think of “autonomous mobility” as something that will drive our cars, driverless technology applications extend to forklifts in factories, tractors on farms, military tanks, mining trucks, heavy construction machinery, marine research vessels and more. Even supply-chain logistics will be transformed by autonomous long-haul freight trucking, railways and marine shipping.

Hexagon's autonomous technologies underpin this ecosystem and are enabling the widespread deployment of autonomous mobility across a variety of industries and applications.

The 22 billion km test drive

With its promise of vast gains in efficiency and dramatic reductions in carbon emissions, it seems autonomous mobility can't come fast enough. Regulatory bodies identify safety as their number one priority before driverless vehicles become widely adopted.

For example, building a safe, driverless car requires the testing of millions of different scenarios and driving conditions. Imagine driving 500 cars at 100 km per hour, 24 hours a day, for 54 years. That’s the magnitude of the task developers face to produce the vehicles of the future.

If manufacturers can determine how to produce safe, autonomous vehicles at scale, the world will reap enormous benefits. For example, heavy construction, agriculture and mining will be safer and more productive. On the road, government agencies predict a 90% reduction in traffic deaths and up to five times more lane capacity, reducing travel time and traffic. The environment will benefit from more efficient mobility, with a 10% improvement in fuel economy and a 60% drop in CO2 emissions.

Hexagon is accelerating the transition to autonomous mobility through our R&D efforts, as well as our design, simulation and manufacturing technologies.

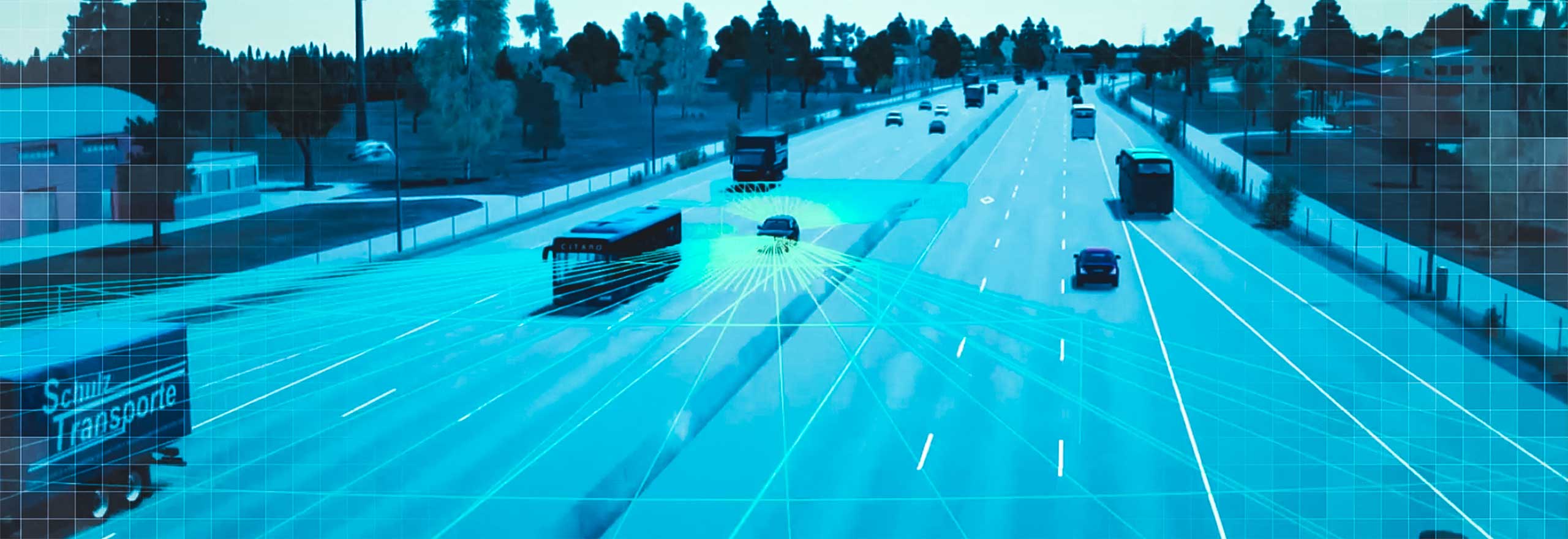

Virtual testing of autonomous mobility

Testing every possible scenario at a scale required to enable safe and successful autonomous mobility is not feasible in the physical world, but it is in a digital world. With our advanced simulation tools, assured positioning solutions, high-definition mapping and sensor fusion capabilities, Hexagon’s customers can virtually test millions of autonomous mobility applications across air, land and marine applications.

Capabilities

Hexagon’s autonomous technology solutions are critical to capturing, connecting and fusing the vast amounts of data required to deliver the world’s safest, most advanced autonomous mobility solutions for on- and off-road vehicles and equipment, marine vessels, drones, robots and more.

Enable autonomous mobility systems across a diverse set of vehicle platforms and industrial applications with autonomous mobility research and development platforms.

Create a seamless workflow between real-world and simulated environments with autonomous mobility testing, which accelerates, optimises, verifies and validates billions of test drive kilometres and real-world scenarios.

Scale quickly from prototype R&D and testing phases to production in a variety of emerging and fast-paced autonomous market segments.