WORKNC Robot Machining

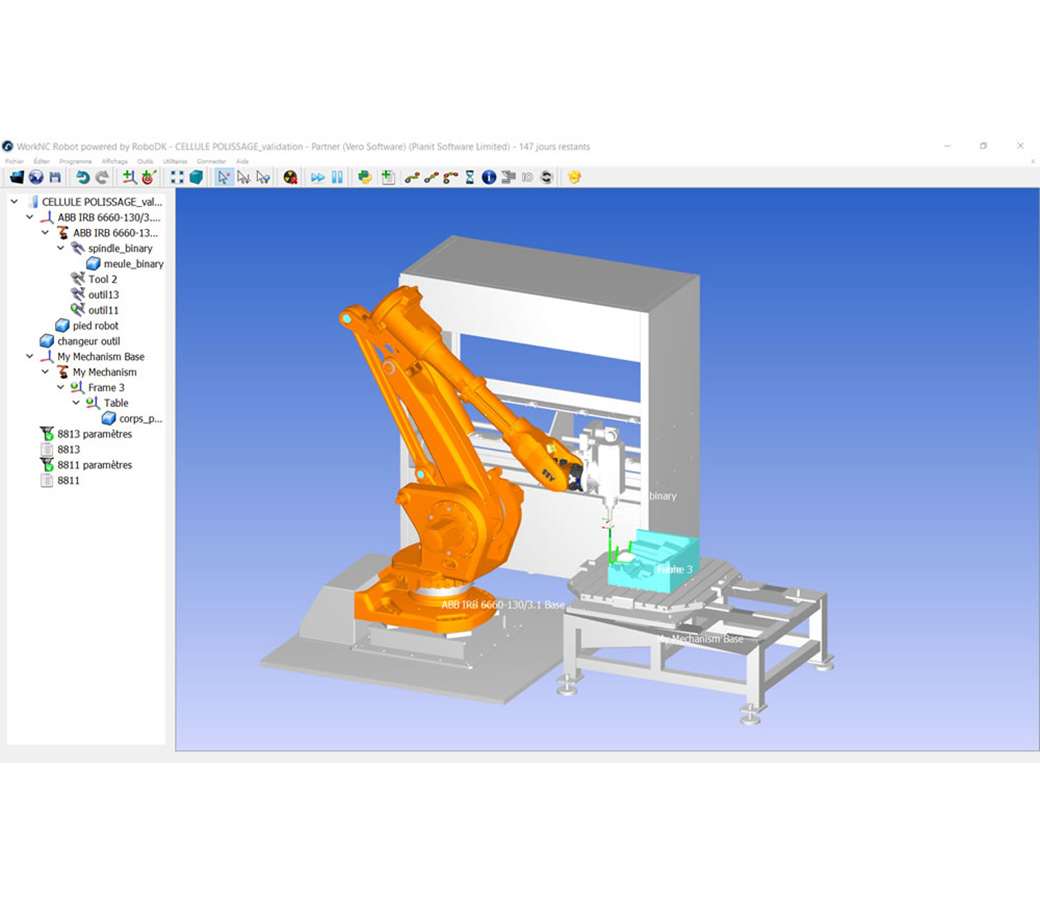

WORKNC integrates the WORKNC Robot module for toolpath simulation and editing enabling the control of all types of robots. WORKNC Robot uses the full range of WORKNC toolpaths for machining operations, edge hardening, welding and polishing.

Easy, rapid and precise programming for robotic applications

WORKNC Robot allows you to simulate and edit tool paths for a wide range of robots.

Ready to learn more?

Product capabilities

Features at a glance:

- Integrated module

- Management of all cell elements

- Collision detection and management

- Singularity detection and management

- Complementary robot position

- Customised postprocessor for all applications

- Pre-positioning of the robot at first point

- Pre-defined head orientation

- Supplementary linear or rotational axis management.

Easy to use

WORKNC Robot’s graphic user interface offers easy, rapid and precise programming resulting in the generation of complex toolpaths for all types of materials and machines. This simple programming process allows manufacturers to realize the full potential of their robots.

All WORKNC strategies (3, 3+2 or simultaneous 5 axis) can be employed to fulfill all the various manufacturing jobs such as milling, part cutting, etc., with the equipment available in the shop floor.

WORKNC Robot replaces the point to point learning cycle for part trimming.

Specific requirements

Today, in addition to milling applications, WORKNC offers solutions in other fields.

Stamping tool edge hardening controlled by WORKNC allows this process, often done manually, to be automated and pilot laser heads mounted on NC milling machines or robots.

WORKNC Robot generates trajectories on complex geometric forms (STL meshes or Nurbs surfaces) which can be personalised for laser or torch welding.

‘Complex’ robot movements require a precise CAD model of the robot cell in order to detect eventual collisions between different elements, such as the robot, the tool changer magazine, the table or other supports, supplementary axes and safety barriers.

Trajectory optimisation - Singularity

Trajectories can provoke singularity problems in robot wrists and arms. WORKNC Robot can automatically detect potential singularity conditions in trajectories and warn operators so that they can take the appropriate action.

Simulation inside the Robot application allows robot movements to be optimised. The module offers robot configurations or complementary positions to ensure optimised trajectories.

High trajectory precision guarantees top quality finished products.

Different cell processes or configurations

Tool-mounted robots

A tool-mounted robot cell configuration allows the machining or the application of various processes on very large parts and heavy parts.

This process offers the possibility of changing tools or machining equipment on the robot thanks to the use of tool changer magazine. Several tools can be simultaneously positioned on the robot head.

Part-mounted robots

This type of solution is proposed for serial production purposes on smaller parts limited by robot capacities.

This process allows automated cells to be controlled from loading blanks onto a conveyor belt to complete machining and placing the part back on the conveyor belt.

WORKNC Robot can pilot any type of robot from 4 to 7 axes as well as supplementary axes, such as rotating tables, rail-mounted robots, gantries with 3 linear axes, etc.

WORKNC Robot offers a library with 250+ existing machines, from over 22 supplied.

Types of robots

WORKNC Robot can be adapted for all brands of robots.

The WORKNC Robot postprocessor, configurable according to production facilities, creates programs which pilots all types of robots considering all possible parameters thanks to a specific simulator dedicated to each controller:

STAUBLI (VAL3, Version 6 and 7)

ABB

FANUC

YASKAWA_Motoman

KUKA