Radio signals for reliable precision of large parts

Bomacon B. V. - Netherlands

Contact us

Contract manufacturing for large parts and components raises many problems and requires high flexibility. Lot sizes range from only 1 piece up to 20 pieces and only rarely up to 50 or 100 pieces. The workpiece dimensions vary greatly, as do the shapes and the cutting requirements.

Whatever is needed – whether it is just finishing external surfaces and holes, complete machining, internal or external machining, whether round or square – anything can be asked for. In addition, there is generally great time pressure to be dealt with.

Therefore, a company that specializes in this direction must reserve a sufficient number of various kinds of large processing machines in various sizes. To ensure a quick response time, it is necessary to be equipped with a wide range of tools, not least in order to be able to process any material.

Finally, there is the question of quality assurance and of measuring in production, since there usually is a lack of time and money to produce gauges or measuring devices. But how can measurements be made at long distances on the machine and possibly even of the inside fit of workpieces?

The company Bomacon of Weert, the Netherlands, near the German border, has specialized in such tasks and has experienced a steadily increasing demand for contract manufacturing of large parts of all kinds, but also with increasing quality requirements. The reason for this is the fact that the manufacturers of such large components themselves often do relatively little machining and thus cannot really utilize to capacity their large machines that have mostly required large financial investments. Which in turn means poor cost effectiveness. This does not apply to a specialized supplier such as Bomacon. Bomacon usually receives its orders from different customers and is thus able to utilize its large machines to a higher capacity. Due to its specialization, it is often able to offer significantly better cutting jobs in less time and with higher quality.

Finally, there is the question of quality assurance and of measuring in production, since there usually is a lack of time and money to produce gauges or measuring devices. But how can measurements be made at long distances on the machine and possibly even of the inside fit of workpieces?

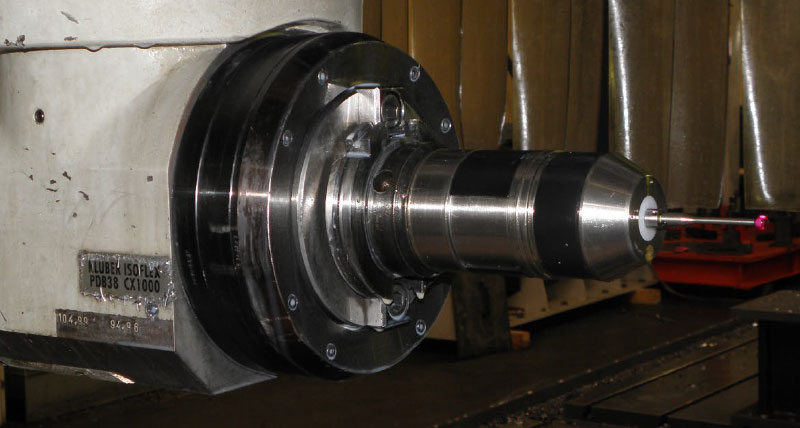

The company Bomacon of Weert, the Netherlands, near the German border, has specialized in such tasks and has experienced a steadily increasing demand for contract manufacturing of large parts of all kinds, but also with increasing quality requirements. The reason for this is the fact that the manufacturers of such large components themselves often do relatively little machining and thus cannot really utilize to capacity their large machines that have mostly required large financial investments. Which in turn means poor cost effectiveness. This does not apply to a specialized supplier such as Bomacon. Bomacon usually receives its orders from different customers and is thus able to utilize its large machines to a higher capacity. Due to its specialization, it is often able to offer significantly better cutting jobs in less time and with higher quality.Bomacon has a machinery consisting of large machining centres, which include among others two Unisign machines of the Univers and Uniport types as well as one MTE. With this machinery, workpieces having dimensions of up to 8 m x 2.5 m x 2 m can be machined. These machines are equipped with probes by m&h which transmit their signals by radio to the control. These signals are transmitted in a protected industrial radio bandwidth around 433 MHz, which is the basis for a secure and interference-free transmission. The m&h probes have a strong transmitting power, enabling transmission over long distances and also from the inside of workpieces. The m&h receivers also check all of their 64 freely adjustable channels to detect any foreign signals during the entire duty cycle of each machine If significant signals are received that could jeopardize a secure transmission of its own commands, the affected channels are disabled for the probes. This not only prevents the machine from stopping due to external signals, but also from interfering with neighbouring machines which are also equipped with radio data transmission probes. Each machine uses its own permanently set channel. Moreover, this technology, which has been used successfully for years, serves to enable the signals to reach the control quickly and without delay. „I have come to appreciate m&h touch probes already in my previous job,“ says Pieter Boots, Director of Bomacon.

"When you find something good, you keep going back to it."

When you find something good, you keep going back to it

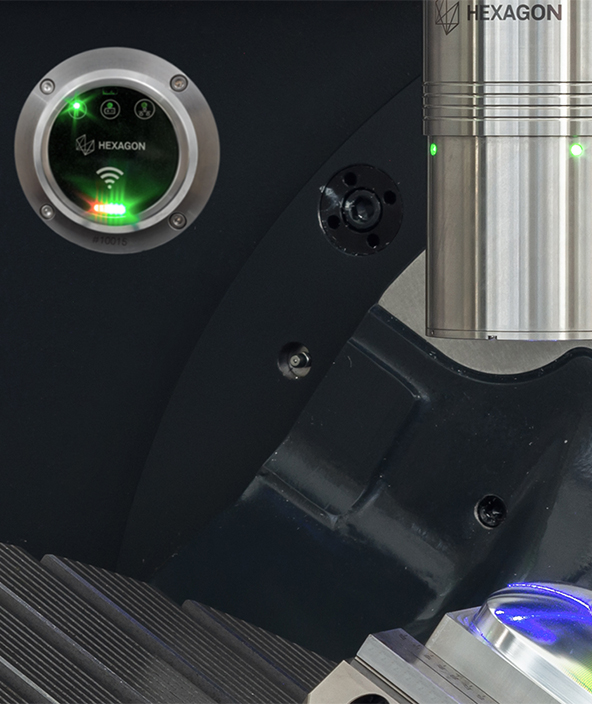

But reliable data transmission is not the only strong feature of the m&h probes. They also feature robust probe bodies made of stainless steel with encapsulated electronics. These are sealed according to the IP68 standard that have been developed specifically for heavy-duty use in machine tools. This means the probes can be easily used in both manufacturing operations and in tool magazines. The slim receiver, which is attached outside the machine housing, always displays its state as well as the state of the probe to the operator.

Thus, for example, there is a timely signal to inform the operator when the battery of the probe should be changed. The operator can then do this whenever it is convenient. The replacement of commercially available batteries can be done in less than a minute without any tools for the m&h probes, with only a few simple steps. Unlike competitors‘ devices, the m&h touch probes will not lose their channel settings when the batteries are changed. After the new battery has been inserted, they are immediately ready for use. The usual tuning and synchronization of transmitter and receiver with all its handling problems has been completely eliminated. This saves time and prevents disturbances in the production process and interference with neighbouring systems.

For Bomacon, the touch probes in the machines are essential, especially since more and more precision is required. Manufacturing tolerances are becoming increasingly restricted. As a result, more measuring must take place.

For this reason, the next machine, another UNISIGN portal machine with a maximum workpiece size of 4,000 x 3,000 x 1,400 and a turntable with a diameter of 2,500 which will be available from April 2013, will also be equipped with an m&h touch probe. Since more and more customers are demanding a measurement report for delivered parts, such reports will in future be created at Bomacon with the m&h 3D Form Inspect software during the clamping on the machine. The program compares the actual workpiece contour with the requirements from the CAD drawing in only a few minutes. „This works very well with m&h, and we would also like to offer it our customers,“ Pieter Boos commented, pleased with his new service, which additionally saves time and increases production safety.