Simufact Forming

Specialised forming simulation software for virtual testing and process design for component optimisation

Metal Forming Excellence

Advanced simulation software orchestrates metal forming, unlocking the art of successful cold forming, hot forging, rolling, and stamping.

Ready to get started?

Software solution for forming processes without expert knowledge

Simufact Forming is a simulation tool for the practitioner in forming technology. Our claim is to consistently align the software to the practical needs of the user.

Often, expert knowledge is required to operate simulation environments in order to build and program complex models. This is not the case with Simufact Forming. The user does not have to deal with the gray physics of the forming process nor with simulation specific details. Simufact Forming is practical and can be learned quickly and easily. The forming practitioner can thus concentrate on the details of his forming processes instead of on the software.

Exactly the right forming process you need

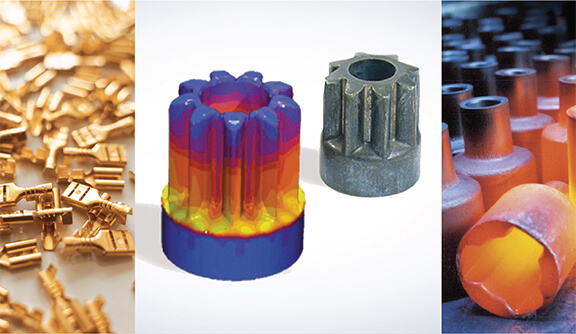

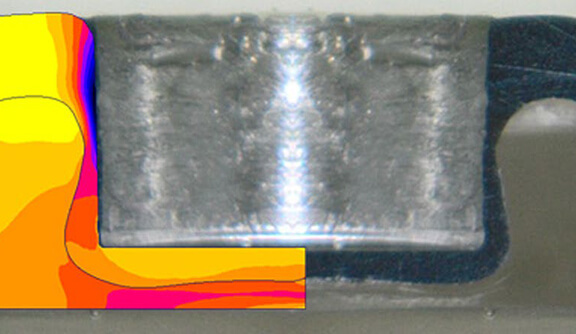

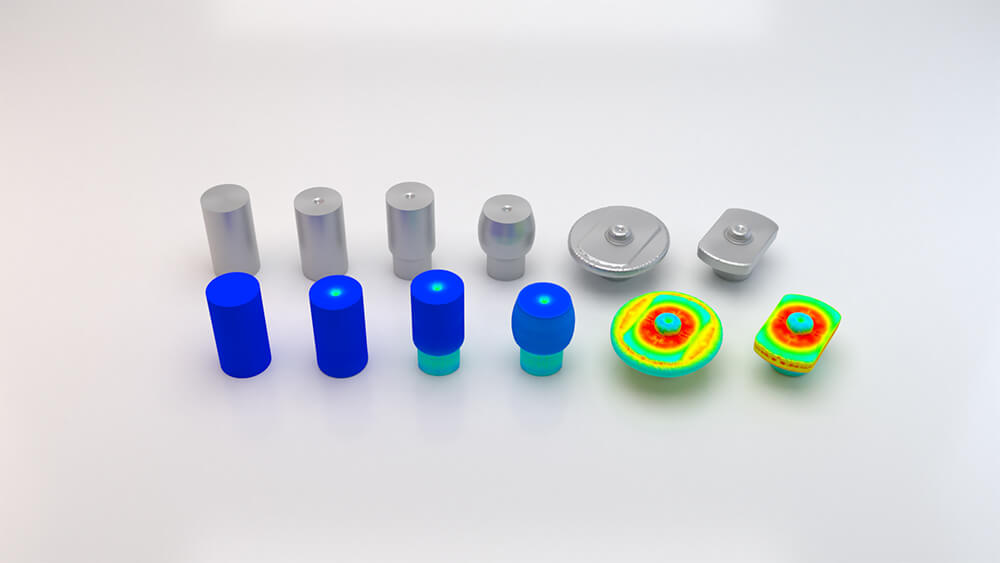

Forming processes conducted significantly below the recrystallisation temperature of the material. These processes include typical upsetting and extrusion processes (e. g. for the production of bolts, nuts and rivets), but can also include coining, cold hobbing, thread rolling and last but not least drawing processes (e. g. wire drawing, tube drawing and profile drawing).

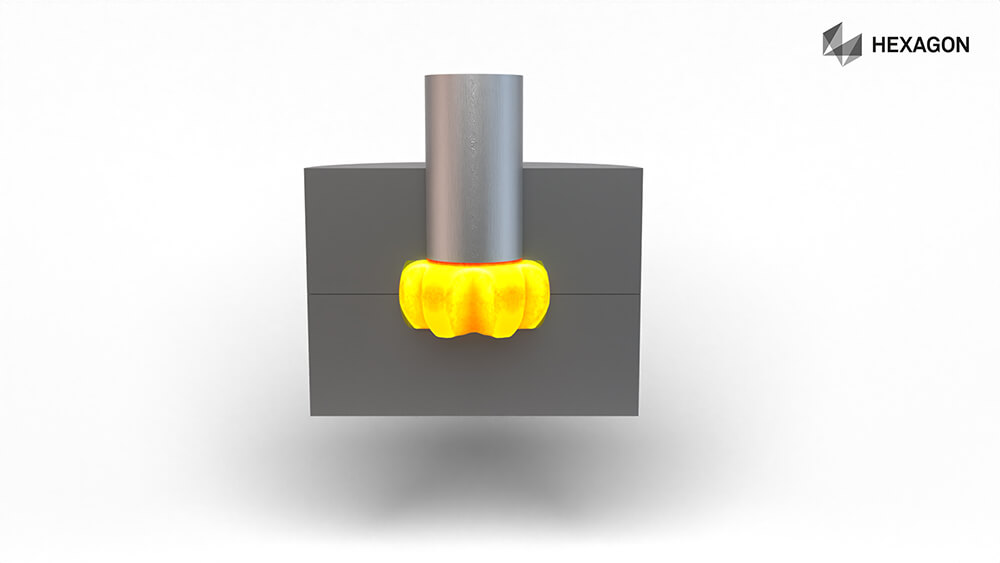

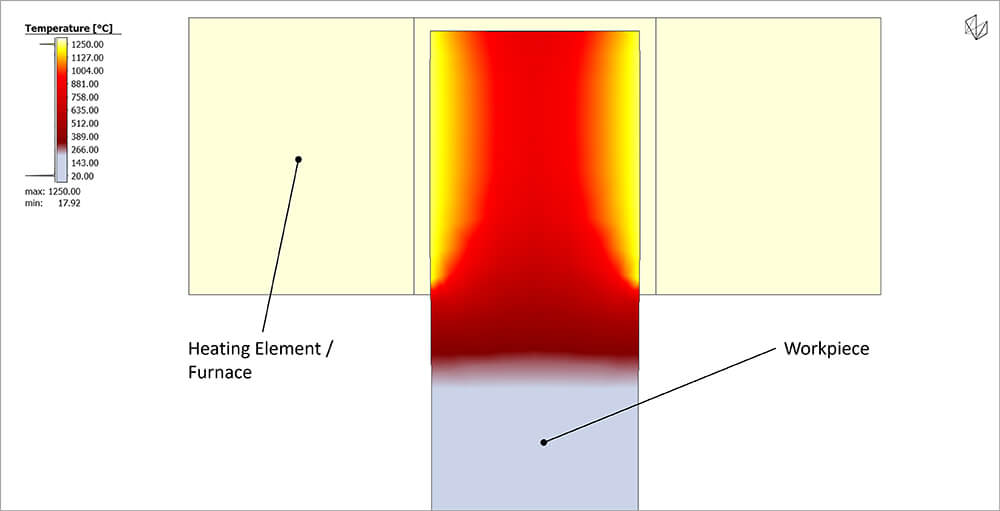

Forming processes conducted above the recrystallisation temperature of the material. A typical process is hot forging, including closed die hot forging, auxiliary processes such as heating and cooling, cutting processes and preform operations (e. g. upsetting, bending, forge rolling and cross wedge rolling) as well as extrusion processes.

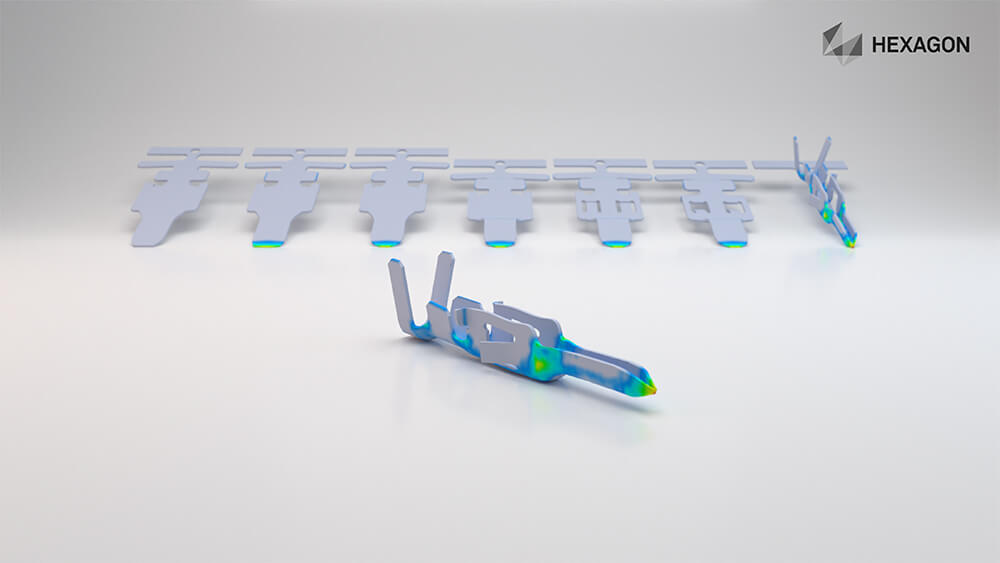

Different methods of sheet metal forming can be used depending on the geometry of the desired part. Based on the characteristics of each deformation process, the forming engineer can choose between: Deep drawing, ironing, punching, bending, stamping, and a variety of other manufacturing processes. Due to the geometric complexity of the parts being manufactured, additional multistage forming that combines different processes is frequently required within a phase of production. Therefore, production is usually achieved by automated transfer or stage pressing, or by progressive tools.

Forming processes in which the shape of the workpiece is changed incrementally (i. e. step-by-step) by repeated, local forming using geometrically simple dies which move relative to the workpiece. Open-die forging includes among others cogging, radial forging, rotary swaging, shell forging and rotational partial forging.

Rolling

Forming processes in which the material is formed between two or more rotating dies (rollers). Examples of rolling processes include; flat and profile rolling, spinning, flow forming and reduction rolling.

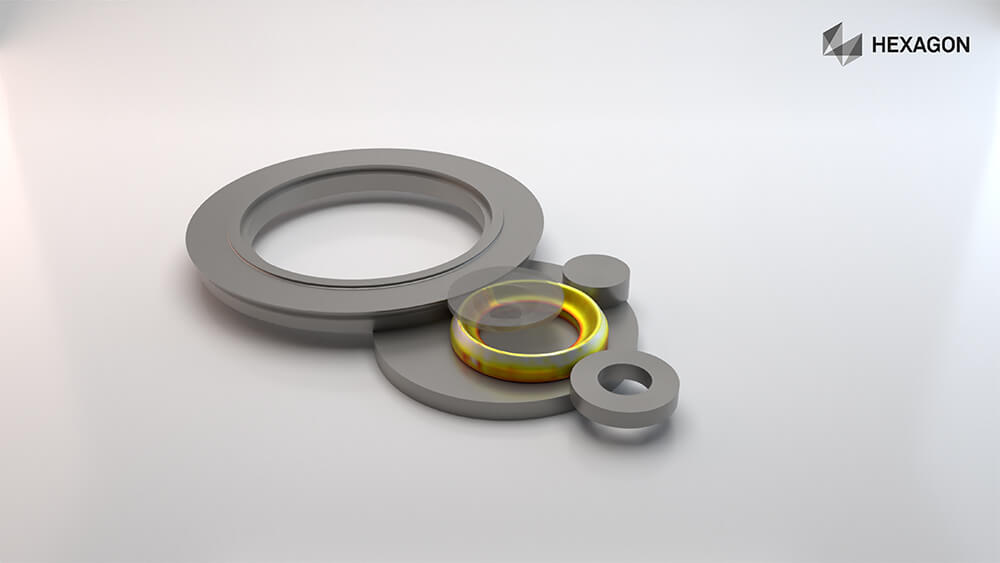

Ring-Rolling

Special rolling method for the manufacturing of seamless rings with related sub-methods such as; radial ring rolling, radial-axial ring rolling and axial closed die rolling.

Methods in which, metallic workpieces (mainly steel pieces) are temporarily heated for the targeted improvement of the material’s properties.

Quench Temper

Quench temper enables the simulation of complex heat treatment processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

Case Hardening

Case hardening enables the simulation of direct hardening processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

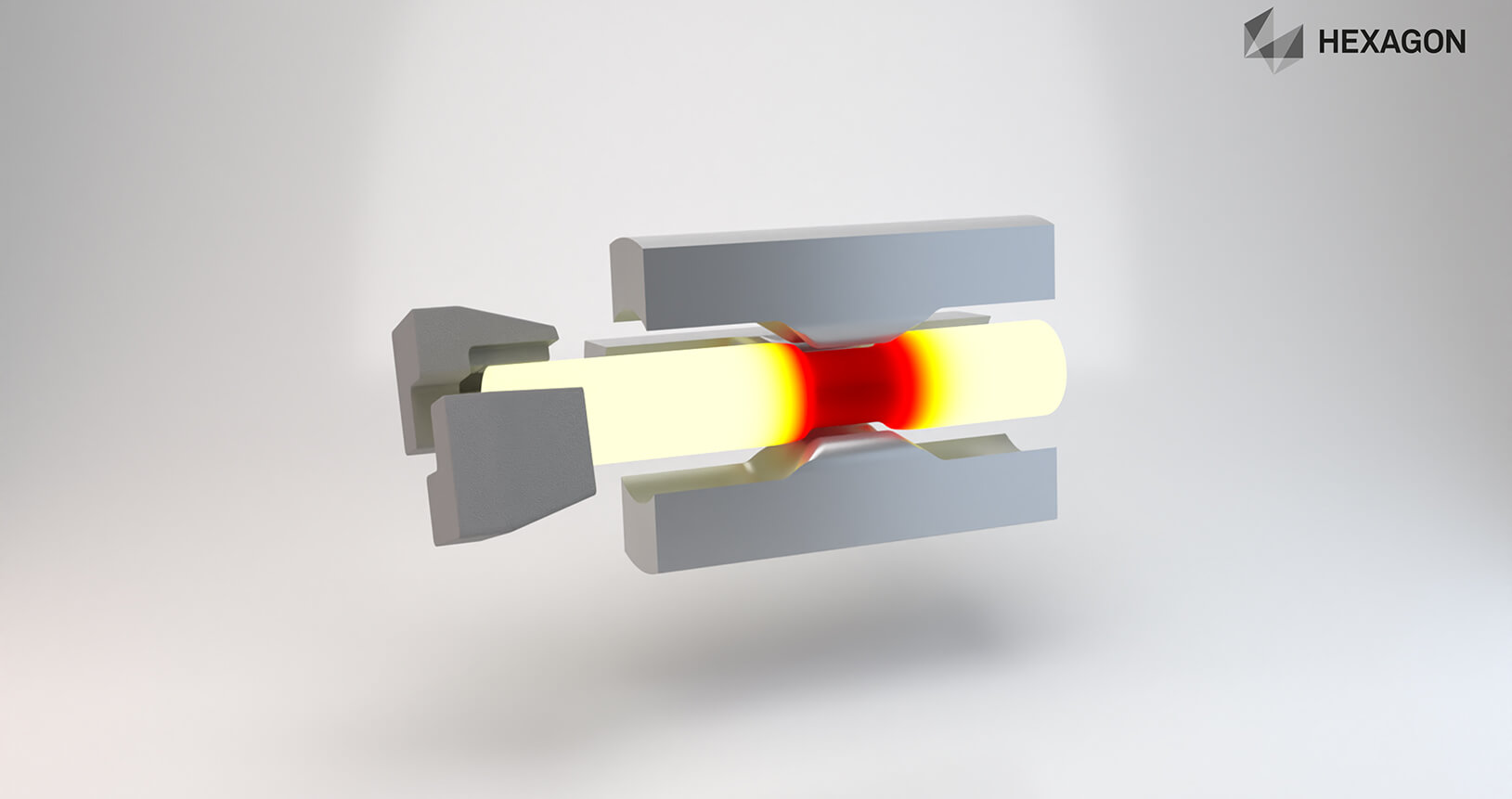

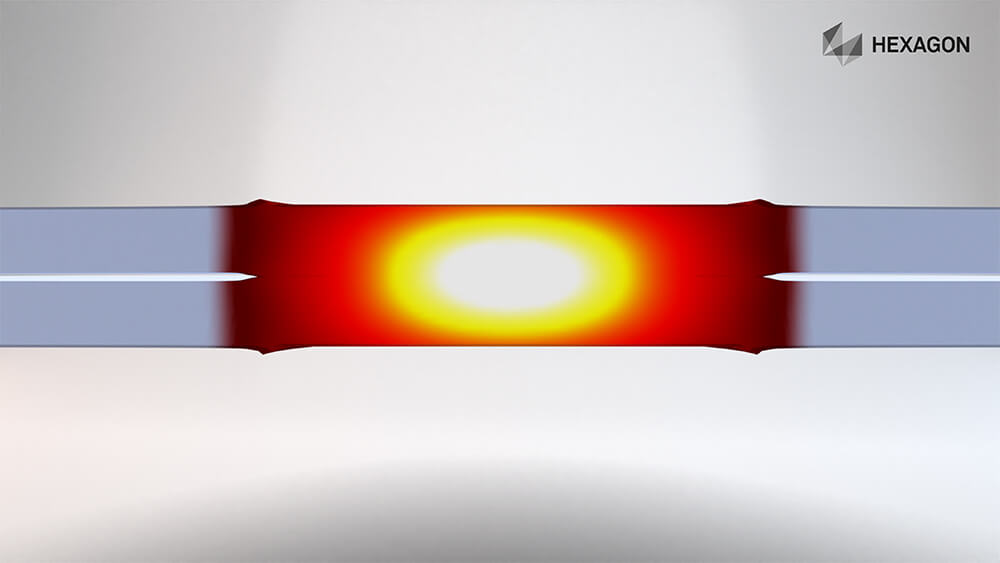

Induction Heating

This process type allows the modelling of an inductive heating process and therefore a more precise estimation of the resulting temperature distibution.

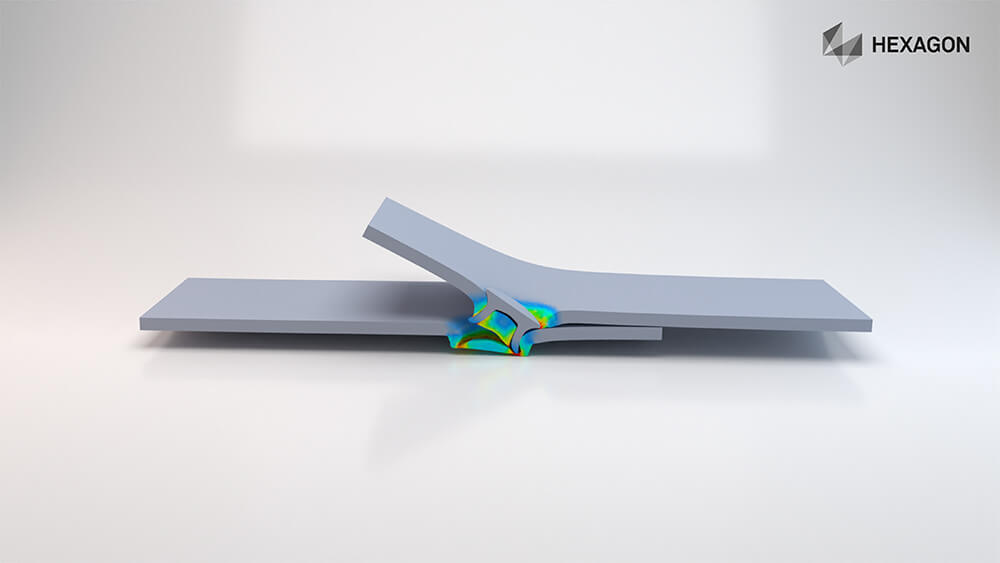

Mechanical Joining

Forming processes that cause a mechanical interlock between the pieces. Mechanical joining includes riveting methods such as; punch riveting, self-piercing riveting and blind riveting, as well as clinching technologies such pressure joining, clinching and toxing.

Resistance Spot Welding

A pressure welding process during which the sheets are pressed together locally with the help of fitted copper electrode welding guns. The electrical current between the weld guns causes a heating and melting of the joining partners, creating a small circular welded area between them.

Pressure Welding

Methods in which, metallic workpieces (mainly steel pieces) are temporarily Pressure welding stands for a group of joining processes in which components are joined by heating and compression. Heat can be generated either via current (resistance welding) or by using friction (friction welding) for the targeted improvement of the material’s properties.

Features in Simufact Forming

Pre-defined Setups for specific Application Modules

Easy Process Setup via Drag and Drop or by Automation through Python Scripting

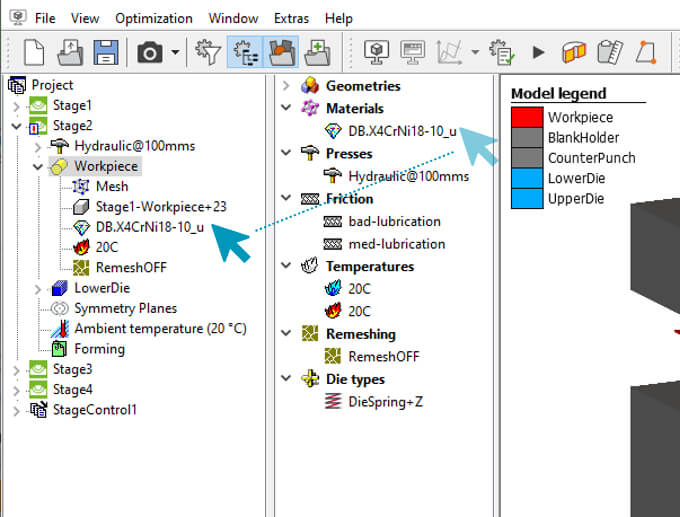

Geometries, materials, kinematics and attributes can be easily and intuitively assigned to one or more processes via drag and drop.

Similarly, automated processes can be carried out via Python skritping. This feature benefits all users by streamlining automation, saving time and preventing errors with comprehensive documentation and prebuilt scripts.

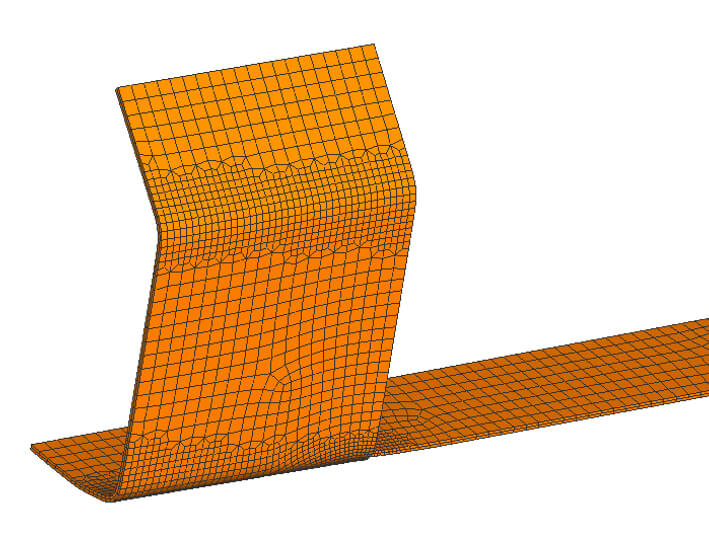

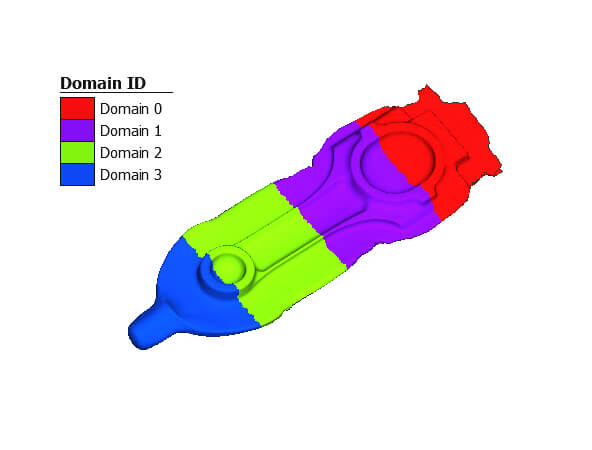

Automatic Meshing & Remeshing

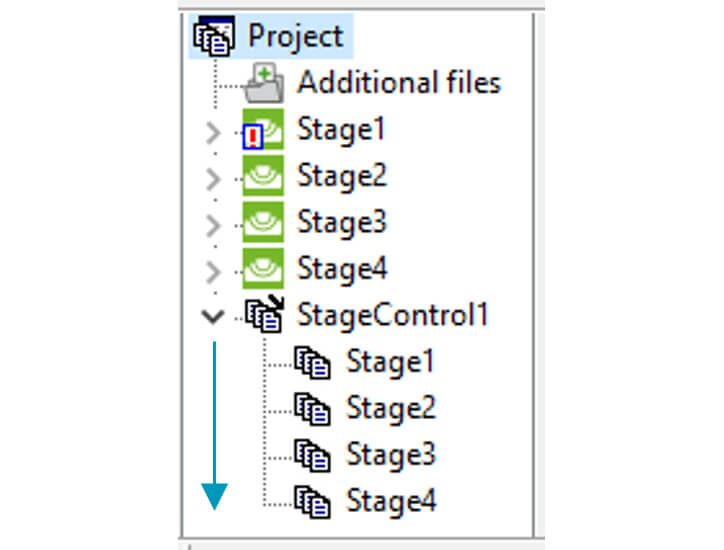

Automated Sub-Stage Simulation

Parallelisation Technologies

Pre-defined Setups for specific Application Modules

Easy Process Setup via Drag and Drop or by Automation through Python Scripting

Geometries, materials, kinematics and attributes can be easily and intuitively assigned to one or more processes via drag and drop.

Similarly, automated processes can be carried out via Python skritping. This feature benefits all users by streamlining automation, saving time and preventing errors with comprehensive documentation and prebuilt scripts.

Automatic Meshing & Remeshing

Automated Sub-Stage Simulation

Parallelisation Technologies

Pre-defined Setups for specific Application Modules

Easy Process Setup via Drag and Drop or by Automation through Python Scripting

Geometries, materials, kinematics and attributes can be easily and intuitively assigned to one or more processes via drag and drop.

Similarly, automated processes can be carried out via Python skritping. This feature benefits all users by streamlining automation, saving time and preventing errors with comprehensive documentation and prebuilt scripts.

Automatic Meshing & Remeshing

Automated Sub-Stage Simulation

Parallelisation Technologies

Pre-defined Setups for specific Application Modules

Easy Process Setup via Drag and Drop or by Automation through Python Scripting

Geometries, materials, kinematics and attributes can be easily and intuitively assigned to one or more processes via drag and drop.

Similarly, automated processes can be carried out via Python skritping. This feature benefits all users by streamlining automation, saving time and preventing errors with comprehensive documentation and prebuilt scripts.

Automatic Meshing & Remeshing

Automated Sub-Stage Simulation

Parallelisation Technologies

Your benefits with Simufact Forming

Design and optimise your forming process:

- Determine the optimal number and sequence of stages and process window with minimal material usage while ensuring a robust manufacturing process.

- Identify and eliminate potential manufacturing defects.

- Optimise tool life.

Simplicity – No expert knowledge required as the software solution is designed to be user-friendly, intuitive and process-oriented.

Sustainability – Save material, time and money by replacing expensive and time-consuming physical tests with virtual tests.

Research Projects

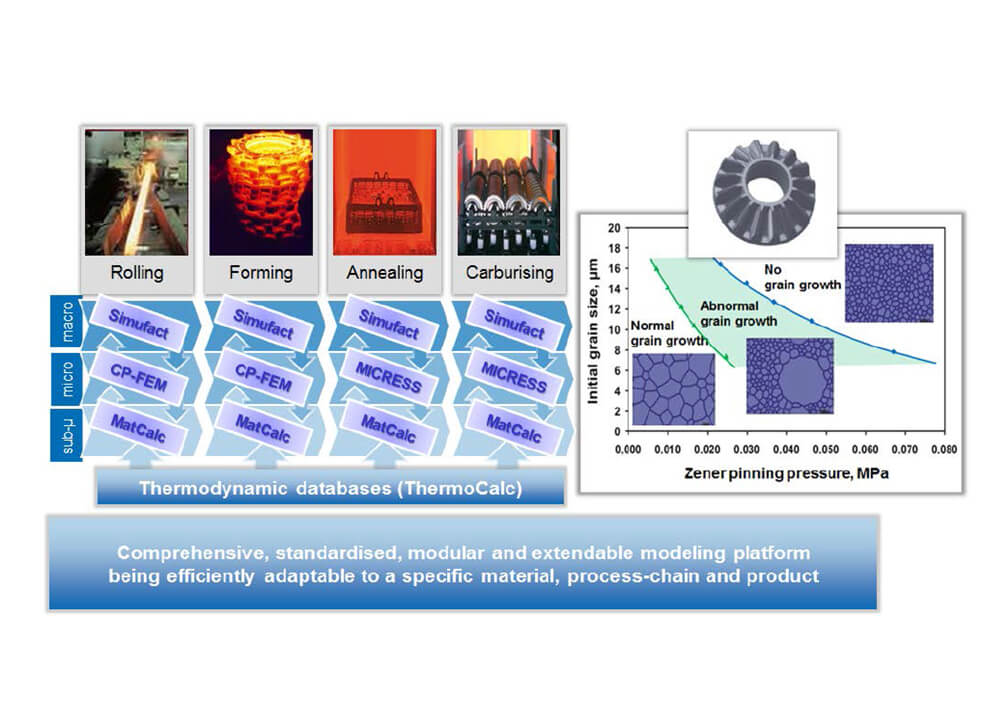

DP Forge Project: Integrative Design of Micro-alloyed DP Forging Steel

DP Forge Project aims to optimize energy-efficient processes for manufacturing forged components using a new DP steel developed through ICME. The project includes creating a validated multi-scale simulation platform for industrial use, standardizing heterogeneous software tools, and collaborating with IEHK (RWTH Aachen), IIT Madras, and Tata Consultancy Services Ltd. Simufact focuses on developing a time-efficient ICME-based simulation solution for forming and annealing processes. (BMBF: 01DQ14003A)

Learn more about Simufact Forming

Flyers & Brochures

Brochure

Design & Engineering simulation solutions

Flyer

Simufact Forming

Brochure

Simufact Forming

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Brochure

Design & Engineering simulation solutions

Flyer

Simufact Forming

Brochure

Simufact Forming

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Brochure

Design & Engineering simulation solutions

Brochure

Design & Engineering simulation solutions

Flyer

Simufact Forming

Brochure

Simufact Forming

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Brochure

Design & Engineering simulation solutions

Flyer

Simufact Forming

Brochure

Simufact Forming

Flyer

HxGN Virtual Manufacturing Suite

Flyer

MSCOne for Manufacturing

Brochure

Design & Engineering simulation solutions

Case Studies

Automotive

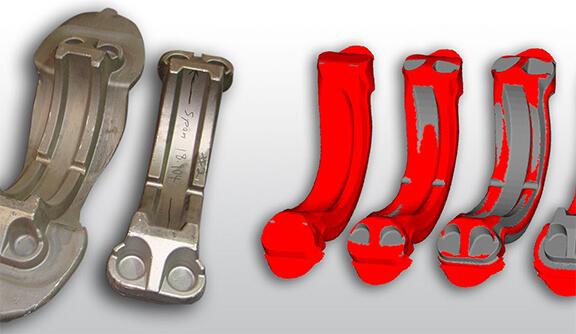

Forming simulation – quality and cost efficiency at Neumayer Tekfor

General Manufacturing

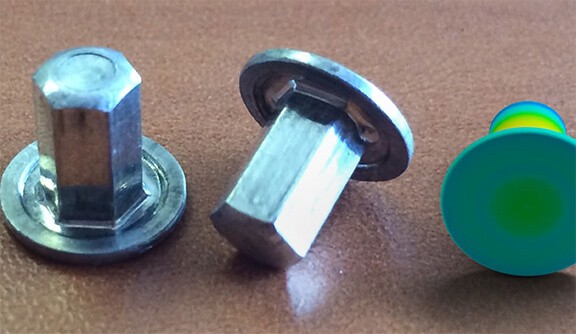

Reducing development costs and time in cold forming tool design with Simufact Forming

General Manufacturing

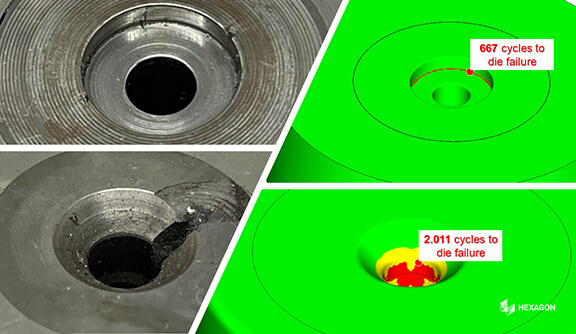

Increasing Die Life through Material Optimisation at Bulten

General Manufacturing

Enhancing Efficiency in Hydro Shaft Manufacturing

General Manufacturing

BOLT FASTENERS uses simulation to predict the tool life

General Manufacturing

Demshe Forge gets the forging process right first time

General Manufacturing

Innovative joining process developed with Simufact Forming

Automotive

LuK innovates manufacturing processes..

General Manufacturing

Process optimisation through forming simulation

General Manufacturing

Forming simulation streamlines manufacturing process of large forgings

Automotive

Forming simulation – quality and cost efficiency at Neumayer Tekfor

General Manufacturing

Reducing development costs and time in cold forming tool design with Simufact Forming

General Manufacturing

Increasing Die Life through Material Optimisation at Bulten

General Manufacturing

Enhancing Efficiency in Hydro Shaft Manufacturing

General Manufacturing

BOLT FASTENERS uses simulation to predict the tool life

General Manufacturing

Demshe Forge gets the forging process right first time

General Manufacturing

Innovative joining process developed with Simufact Forming

Automotive

LuK innovates manufacturing processes..

General Manufacturing

Process optimisation through forming simulation

General Manufacturing

Forming simulation streamlines manufacturing process of large forgings

Automotive

Forming simulation – quality and cost efficiency at Neumayer Tekfor

General Manufacturing

Reducing development costs and time in cold forming tool design with Simufact Forming

General Manufacturing

Reducing development costs and time in cold forming tool design with Simufact Forming

General Manufacturing

Increasing Die Life through Material Optimisation at Bulten

General Manufacturing

Enhancing Efficiency in Hydro Shaft Manufacturing

General Manufacturing

BOLT FASTENERS uses simulation to predict the tool life

General Manufacturing

Demshe Forge gets the forging process right first time

General Manufacturing

Innovative joining process developed with Simufact Forming

Automotive

LuK innovates manufacturing processes..

General Manufacturing

Process optimisation through forming simulation

General Manufacturing

Forming simulation streamlines manufacturing process of large forgings

Automotive

Forming simulation – quality and cost efficiency at Neumayer Tekfor

General Manufacturing

Reducing development costs and time in cold forming tool design with Simufact Forming

General Manufacturing

Increasing Die Life through Material Optimisation at Bulten

General Manufacturing

Enhancing Efficiency in Hydro Shaft Manufacturing

General Manufacturing

BOLT FASTENERS uses simulation to predict the tool life

General Manufacturing

Demshe Forge gets the forging process right first time

General Manufacturing

Innovative joining process developed with Simufact Forming

Automotive

LuK innovates manufacturing processes..

General Manufacturing

Process optimisation through forming simulation

General Manufacturing

Forming simulation streamlines manufacturing process of large forgings

Automotive

Forming simulation – quality and cost efficiency at Neumayer Tekfor

General Manufacturing

Reducing development costs and time in cold forming tool design with Simufact Forming

Webinars

Get your forming processes right first time

Python scripting in Simufact Forming

Python scripting in Simufact Forming

Get your forming processes right first time

Python scripting in Simufact Forming

Get your forming processes right first time

Python scripting in Simufact Forming

Related Articles

Technical Article

High temperature quality inspection

White Paper

Reducing costs through virtual simulation

Flyer

EV Battery Enclosure Manufacturing

You may be interested in...

Magazine

Engineering Reality

Suite

Virtual Manufacturing

Product

Simufact Welding

Product

COSTOPTIMIZER Professional

Division

Manufacturing Intelligence division

Magazine

Engineering Reality

Suite

Virtual Manufacturing

Product

Simufact Welding

Product

COSTOPTIMIZER Professional

Division

Manufacturing Intelligence division

Magazine

Engineering Reality

Magazine

Engineering Reality

Suite

Virtual Manufacturing

Product

Simufact Welding

Product

COSTOPTIMIZER Professional

Division

Manufacturing Intelligence division

Magazine

Engineering Reality

Suite

Virtual Manufacturing

Product

Simufact Welding

Product

COSTOPTIMIZER Professional

Division

Manufacturing Intelligence division

Magazine