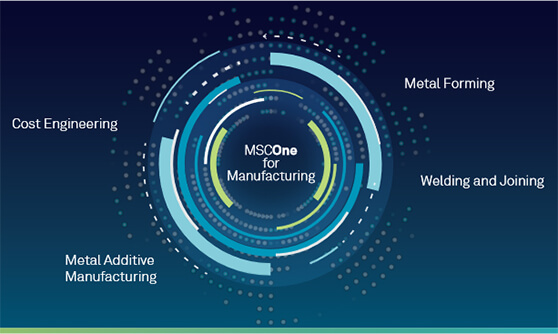

Simufact Forming

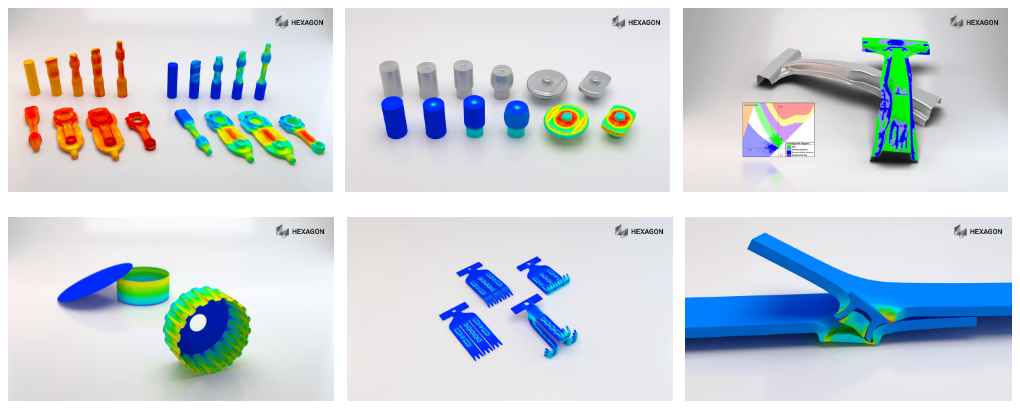

Logiciel de simulation de formage spécialisé pour les essais virtuels et la conception de processus pour optimiser les composants

Solution logicielle

Pour les procédés de formage sans connaissances spécialisées

Simufact Forming est un outil de simulation pour le praticien de la technologie de formage. Nous adaptons systématiquement le logiciel aux besoins de l’utilisateur.

Souvent, des connaissances spécialisées sont nécessaires pour exploiter des environnements de simulation dans le but de construire et de programmer des modèles complexes. C’est différent avec Simufact Forming. L’utilisateur n’a pas à s’occuper de la physique pure et dure du processus de formage ni des détails spécifiques à la simulation. Simufact Forming est un logiciel pratique qui peut être appris rapidement et facilement. Le spécialiste du formage peut ainsi se concentrer sur les détails du processus de formage plutôt que sur le logiciel.

« Aussi simple que possible – aussi complexe que nécessaire »

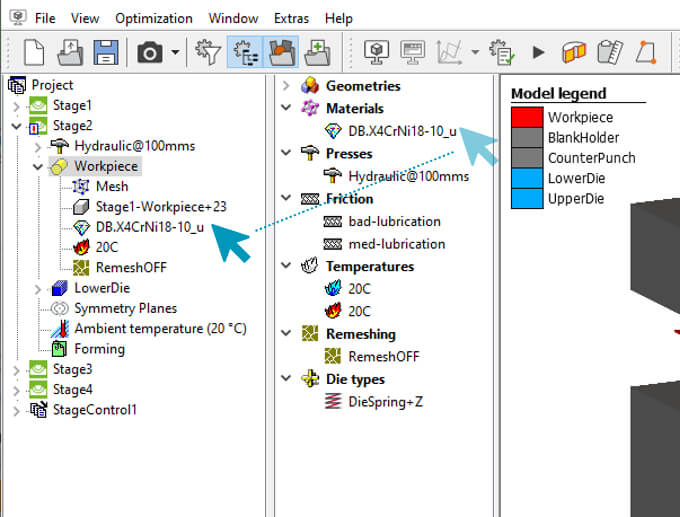

L’interface utilisateur de Simufact Forming a été développée pour être simple, intuitive et orientée processus. Simufact Forming est donc un outil de conception pour le développeur d’outils et de processus qui facilite le travail quotidien de l’utilisateur. En quelques clics de souris, tous les procédés de formage standard peuvent être définis et évalués :

- Formage à froid

- Forgeage à chaud

- Formage de tôle

- Laminage

- Laminage circulaire

- Forgeage libre

- Traitement thermique

- Assemblage mécanique

- Soudage sous pression

Cliquez ici pour en savoir plus sur les différents types de procédé.

Avantages de Simufact Forming

- Conception et optimisation du processus de formage :

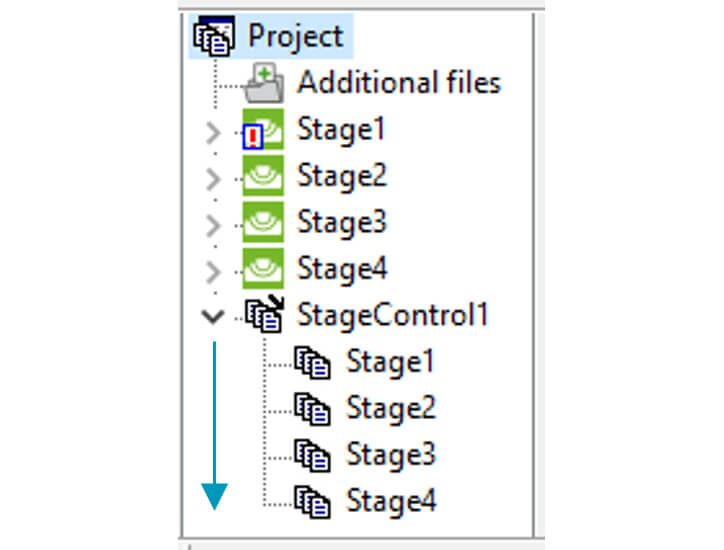

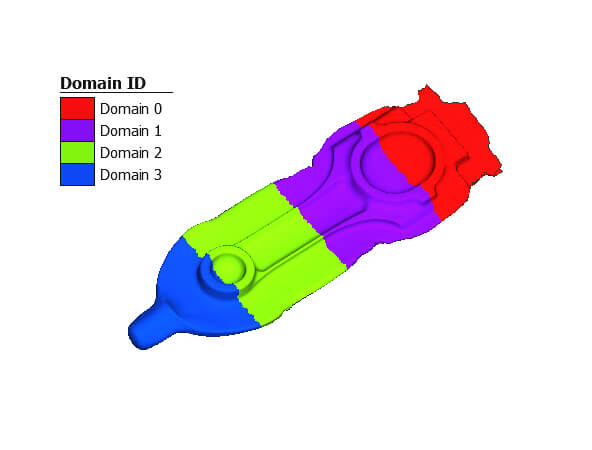

- Détermination du nombre optimal, de la séquence d’étapes et de la fenêtre de processus avec une utilisation minimale de matériaux tout en garantissant un processus de fabrication efficace.

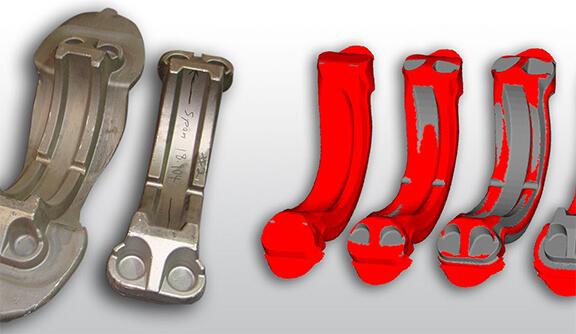

- Identification et élimination des défauts de fabrication potentiels

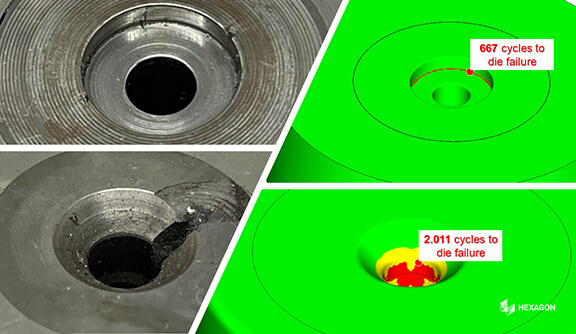

- Optimisation de la durée de vie des outils

- Simplicité – pas de connaissances d’expert nécessaires, car la solution a été conçue pour être conviviale, intuitive et axée sur les processus.

- Durabilité – économies de matériau, de temps et d’argent grâce au remplacement des essais physiques coûteux et chronophages par des tests virtuels.

Pour en savoir plus sur les fonctionnalités et les domaines d’application, consultez le site Simufact.

Exactly the right forming process you need

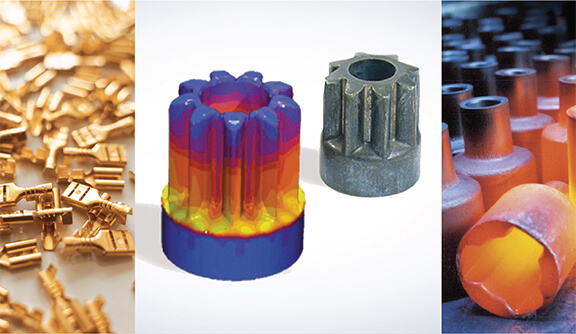

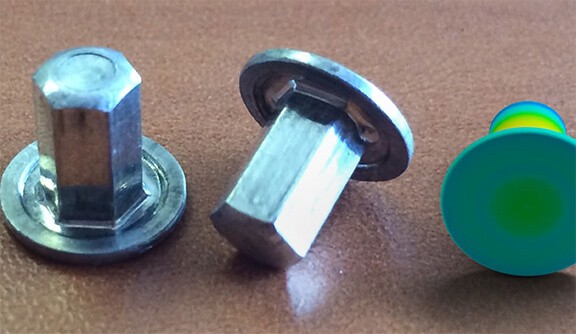

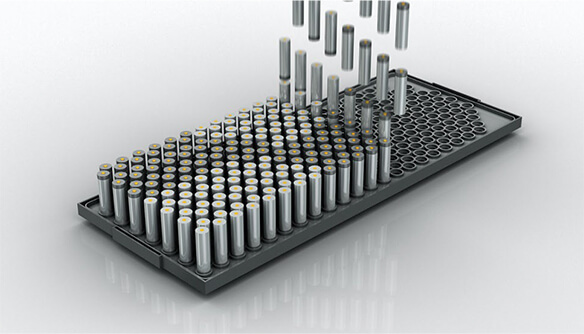

Forming processes conducted significantly below the recrystallisation temperature of the material. These processes include typical upsetting and extrusion processes (e. g. for the production of bolts, nuts and rivets), but can also include coining, cold hobbing, thread rolling and last but not least drawing processes (e. g. wire drawing, tube drawing and profile drawing).

Forming processes conducted above the recrystallisation temperature of the material. A typical process is hot forging, including closed die hot forging, auxiliary processes such as heating and cooling, cutting processes and preform operations (e. g. upsetting, bending, forge rolling and cross wedge rolling) as well as extrusion processes.

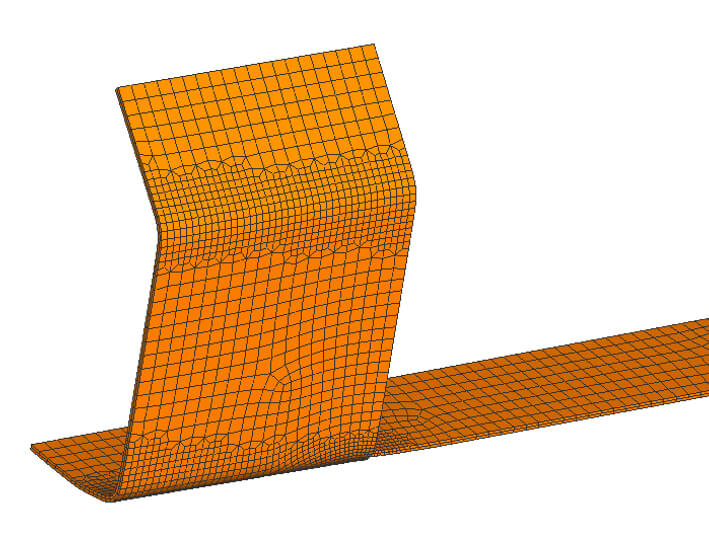

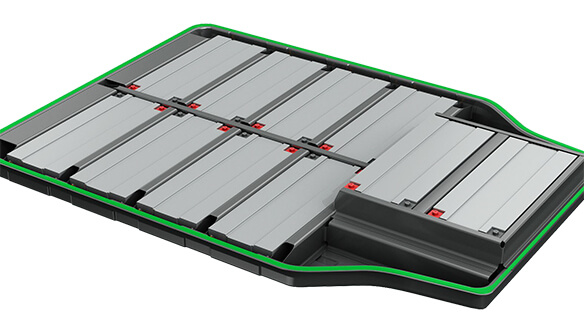

Different methods of sheet metal forming can be used depending on the geometry of the desired part. Based on the characteristics of each deformation process, the forming engineer can choose between: Deep drawing, ironing, punching, bending, stamping, and a variety of other manufacturing processes. Due to the geometric complexity of the parts being manufactured, additional multistage forming that combines different processes is frequently required within a phase of production. Therefore, production is usually achieved by automated transfer or stage pressing, or by progressive tools.

Forming processes in which the shape of the workpiece is changed incrementally (i. e. step-by-step) by repeated, local forming using geometrically simple dies which move relative to the workpiece. Open-die forging includes among others cogging, radial forging, rotary swaging, shell forging and rotational partial forging.

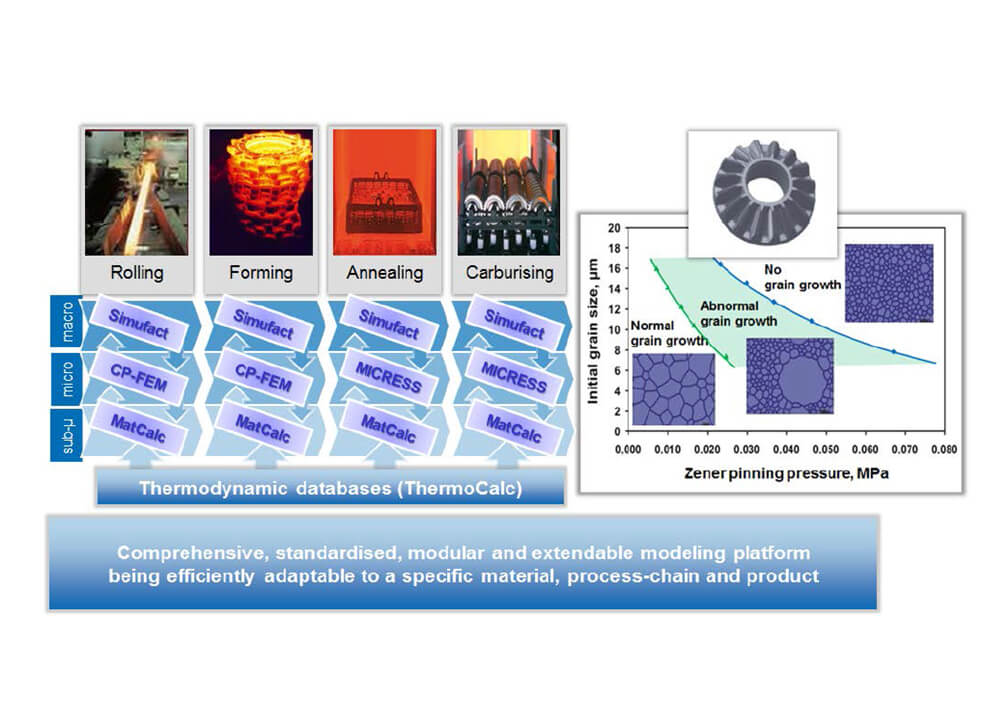

Rolling

Forming processes in which the material is formed between two or more rotating dies (rollers). Examples of rolling processes include; flat and profile rolling, spinning, flow forming and reduction rolling.

Ring-Rolling

Special rolling method for the manufacturing of seamless rings with related sub-methods such as; radial ring rolling, radial-axial ring rolling and axial closed die rolling.

Methods in which, metallic workpieces (mainly steel pieces) are temporarily heated for the targeted improvement of the material’s properties.

Quench Temper

Quench temper enables the simulation of complex heat treatment processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

Case Hardening

Case hardening enables the simulation of direct hardening processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

Induction Heating

This process type allows the modelling of an inductive heating process and therefore a more precise estimation of the resulting temperature distibution.

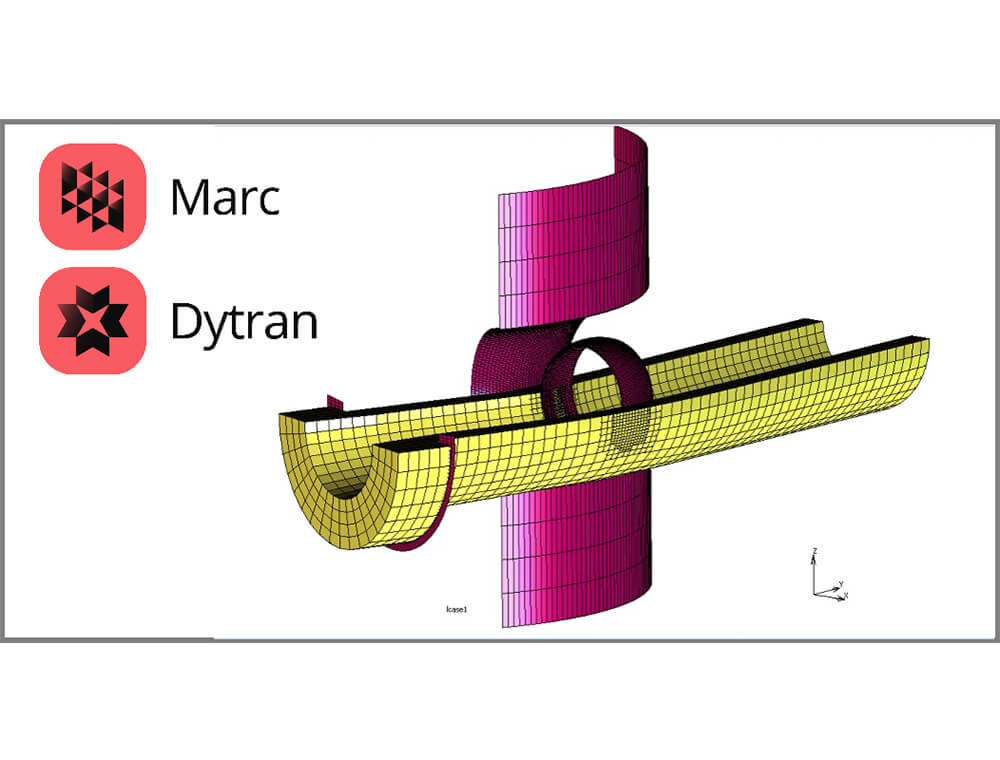

Mechanical Joining

Forming processes that cause a mechanical interlock between the pieces. Mechanical joining includes riveting methods such as; punch riveting, self-piercing riveting and blind riveting, as well as clinching technologies such pressure joining, clinching and toxing.

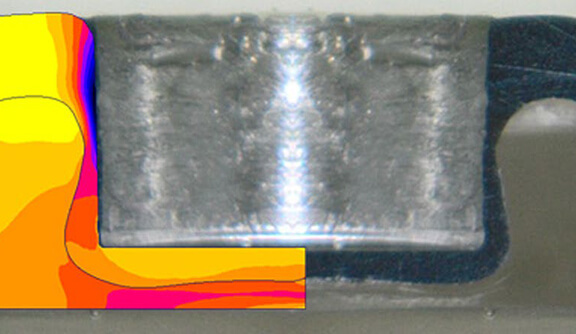

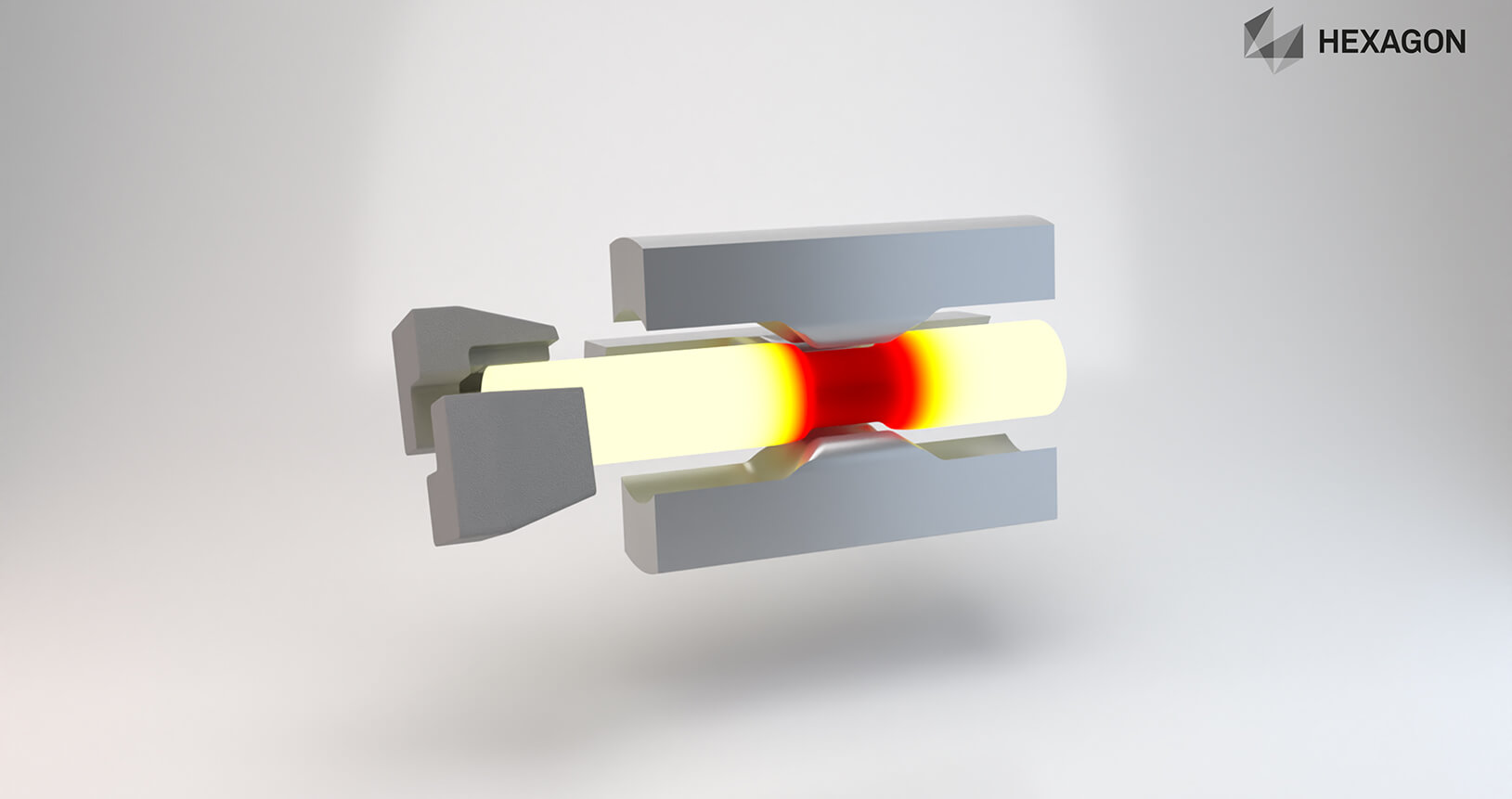

Resistance Spot Welding

A pressure welding process during which the sheets are pressed together locally with the help of fitted copper electrode welding guns. The electrical current between the weld guns causes a heating and melting of the joining partners, creating a small circular welded area between them.

Pressure Welding

Methods in which, metallic workpieces (mainly steel pieces) are temporarily Pressure welding stands for a group of joining processes in which components are joined by heating and compression. Heat can be generated either via current (resistance welding) or by using friction (friction welding) for the targeted improvement of the material’s properties.

Your benefits with Simufact Forming

Design and optimise your forming process:

- Determine the optimal number and sequence of stages and process window with minimal material usage while ensuring a robust manufacturing process.

- Identify and eliminate potential manufacturing defects.

- Optimise tool life.

Simplicity – No expert knowledge required as the software solution is designed to be user-friendly, intuitive and process-oriented.

Sustainability – Save material, time and money by replacing expensive and time-consuming physical tests with virtual tests.

Research Projects

Learn more about Simufact Forming

Related Articles

Technical Article

High temperature quality inspection

White Paper

Reducing costs through virtual simulation

Flyer