Simufact Forming

Spezielle Umformsimulationssoftware für virtuelle Versuche und Prozessauslegung zur Optimierung von Bauteilen

Metal Forming Excellence

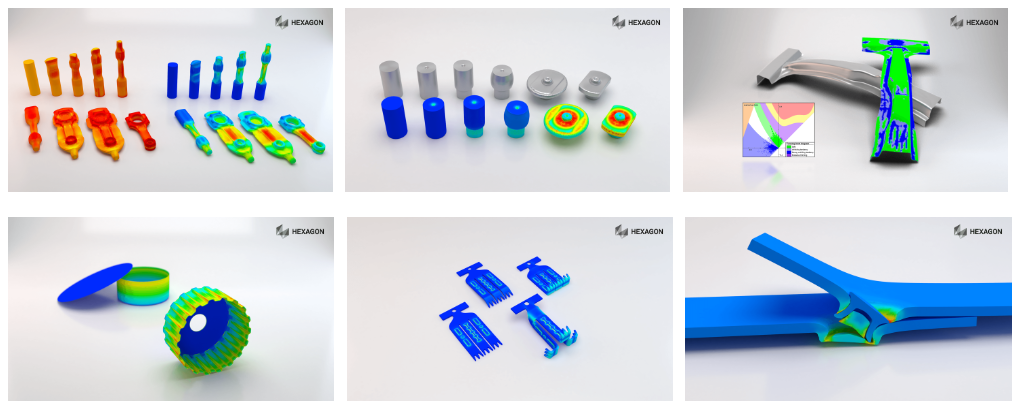

Advanced simulation software orchestrates metal forming, unlocking the art of successful cold forming, hot forging, rolling, and stamping.

Simufact Forming ist ein Simulationswerkzeug für den Praktiker in der Umformtechnik. Unser Anspruch ist es, die Software konsequent an den praktischen Bedürfnissen der Anwender auszurichten.

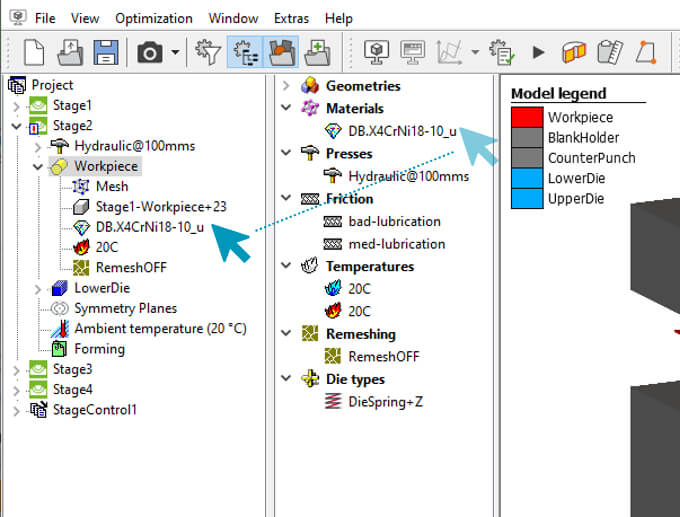

Häufig wird für die Bedienung von Simulationsumgebungen Expertenwissen benötigt, um komplexe Modelle aufzubauen und programmieren zu können. Bei Simufact Forming ist dies nicht der Fall. Der Anwender muss sich weder mit der grauen Physik des Umformprozesses noch mit simulationsspezifischen Details auseinandersetzen. Simufact Forming ist praxisnah und schnell und einfach zu erlernen. Der Umformpraktiker kann sich so, statt auf die Software, auf die Details seiner Umformprozesse konzentrieren.

„So einfach wie möglich – so komplex wie nötig“

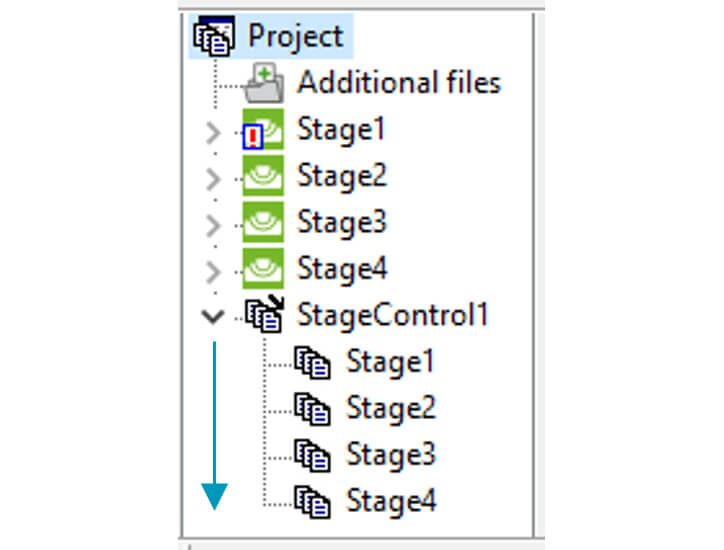

Die Benutzeroberfläche von Simufact Forming wurde so entwickelt, dass sie einfach, intuitiv und prozessorientiert ist. So wird Simufact Forming zum Auslegungswerkzeug des Werkzeug- und Prozessentwicklers, das die tägliche Arbeit des Anwenders unterstützt und vereinfacht. Mit wenigen Mausklicks können alle Standardprozesse der Umformtechnik aufgebaut und ausgewertet werden:

- Kaltumformung

- Warmumformung

- Blechumformung

- Walzen

- Ringwalzen

- Freiformschmieden

- Wärmebehandlung

- Mechanisches Fügen

- Pressschweißen

Klicken Sie hier, um mehr über die einzelnen Prozesstypen zu erfahren.

Ihre Vorteile mit Simufact Forming

- Entwerfen und optimieren Sie Ihren Umformprozess:

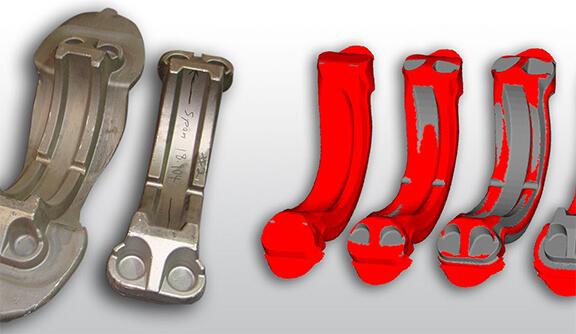

- Bestimmen Sie die optimale Anzahl und Abfolge der Stufen und das Prozessfenster mit minimalem Materialeinsatz bei gleichzeitiger Gewährleistung eines robusten Fertigungsprozesses.

- Identifizieren und eliminieren Sie potenzielle Fertigungsfehler

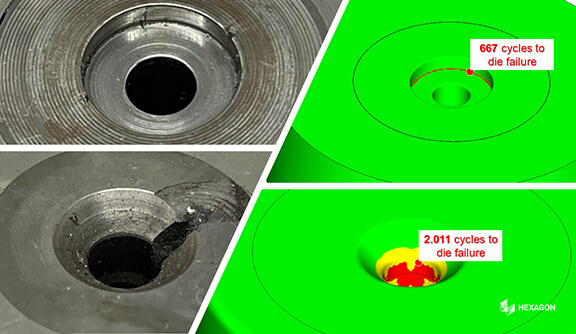

- Optimieren Sie die Werkzeugstandzeit

- Einfachheit – Kein Expertenwissen erforderlich, da die Softwarelösung benutzerfreundlich, intuitiv und prozessorientiert gestaltet ist.

- Nachhaltigkeit – Sparen Sie Material, Zeit und Geld, indem Sie teure und zeitaufwändige physische Versuche durch virtuelle Tests ersetzen.

Mehr über die Funktionen und Anwendungsgebiete erfahren Sie auf der Simufact Webseite.

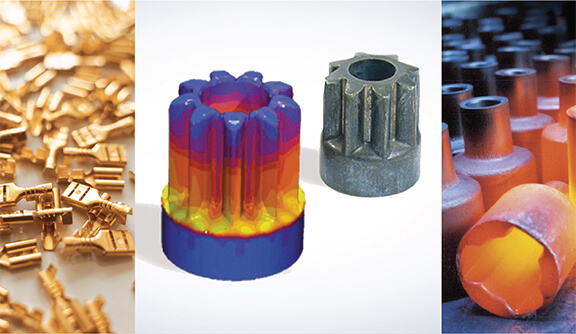

Exactly the right forming process you need

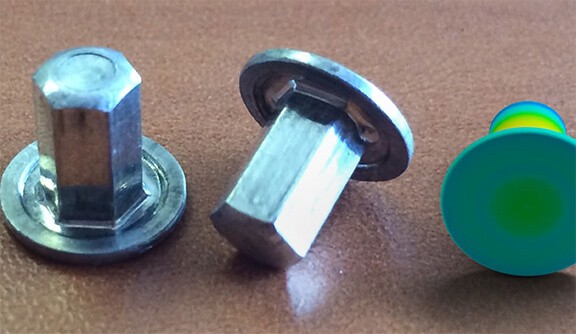

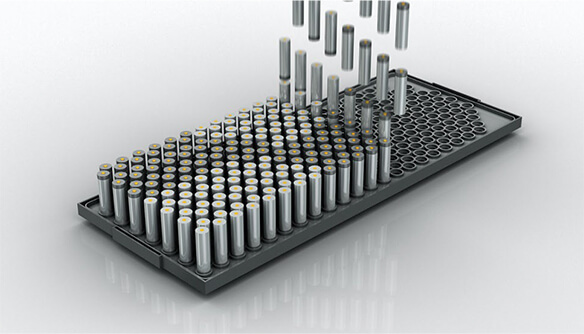

Forming processes conducted significantly below the recrystallisation temperature of the material. These processes include typical upsetting and extrusion processes (e. g. for the production of bolts, nuts and rivets), but can also include coining, cold hobbing, thread rolling and last but not least drawing processes (e. g. wire drawing, tube drawing and profile drawing).

Forming processes conducted above the recrystallisation temperature of the material. A typical process is hot forging, including closed die hot forging, auxiliary processes such as heating and cooling, cutting processes and preform operations (e. g. upsetting, bending, forge rolling and cross wedge rolling) as well as extrusion processes.

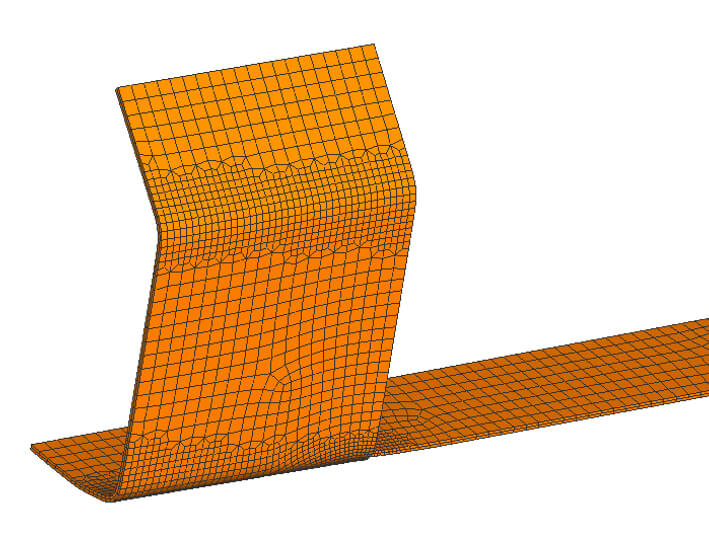

Different methods of sheet metal forming can be used depending on the geometry of the desired part. Based on the characteristics of each deformation process, the forming engineer can choose between: Deep drawing, ironing, punching, bending, stamping, and a variety of other manufacturing processes. Due to the geometric complexity of the parts being manufactured, additional multistage forming that combines different processes is frequently required within a phase of production. Therefore, production is usually achieved by automated transfer or stage pressing, or by progressive tools.

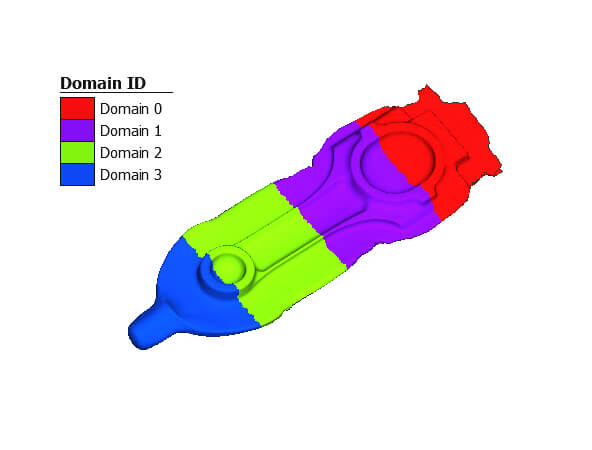

Forming processes in which the shape of the workpiece is changed incrementally (i. e. step-by-step) by repeated, local forming using geometrically simple dies which move relative to the workpiece. Open-die forging includes among others cogging, radial forging, rotary swaging, shell forging and rotational partial forging.

Rolling

Forming processes in which the material is formed between two or more rotating dies (rollers). Examples of rolling processes include; flat and profile rolling, spinning, flow forming and reduction rolling.

Ring-Rolling

Special rolling method for the manufacturing of seamless rings with related sub-methods such as; radial ring rolling, radial-axial ring rolling and axial closed die rolling.

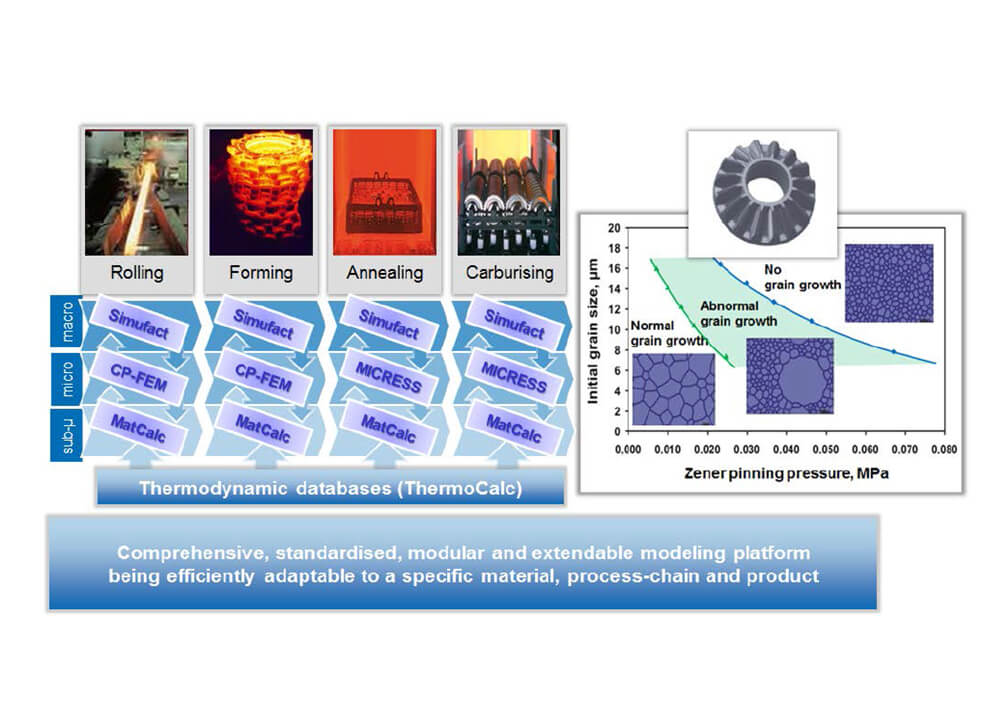

Methods in which, metallic workpieces (mainly steel pieces) are temporarily heated for the targeted improvement of the material’s properties.

Quench Temper

Quench temper enables the simulation of complex heat treatment processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

Case Hardening

Case hardening enables the simulation of direct hardening processes with all necessary stages. In each of them the respective temperatures and heat transfer coefficients of resp. to dies and (furnace) environment can be specified in many ways as constant or changing.

Induction Heating

This process type allows the modelling of an inductive heating process and therefore a more precise estimation of the resulting temperature distibution.

Mechanical Joining

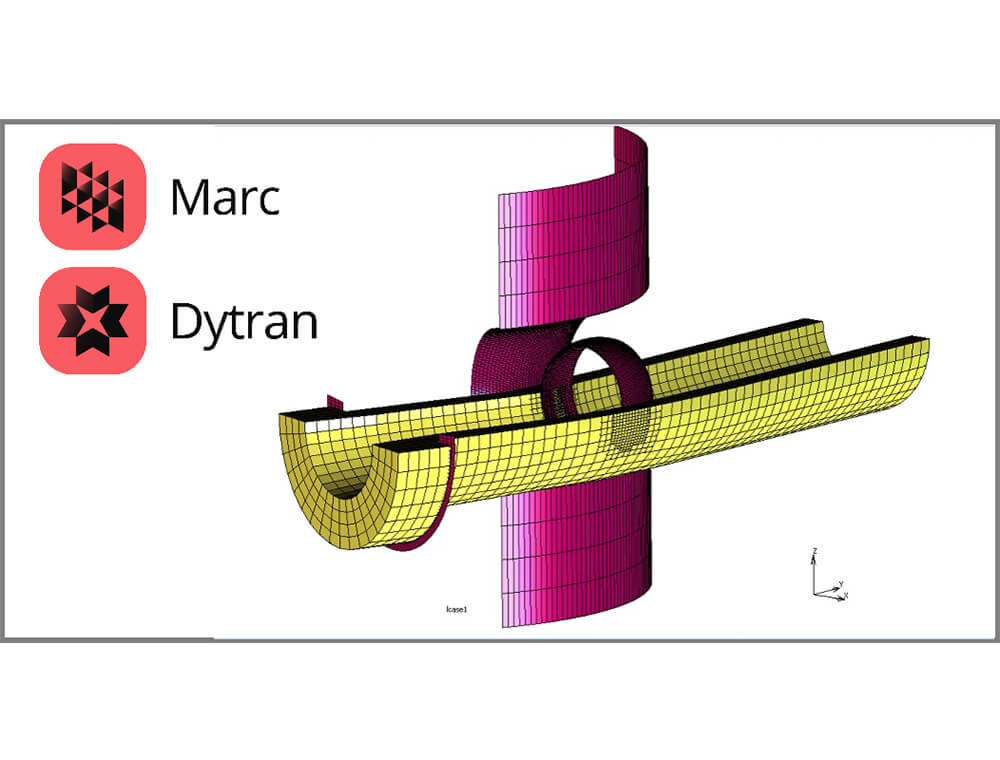

Forming processes that cause a mechanical interlock between the pieces. Mechanical joining includes riveting methods such as; punch riveting, self-piercing riveting and blind riveting, as well as clinching technologies such pressure joining, clinching and toxing.

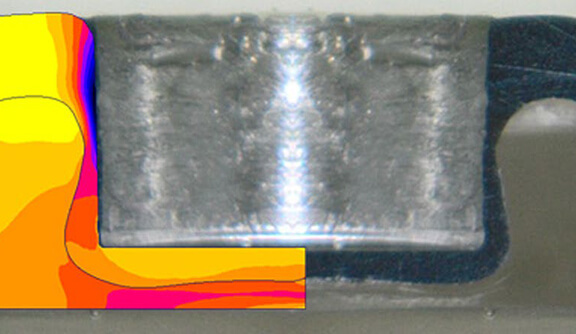

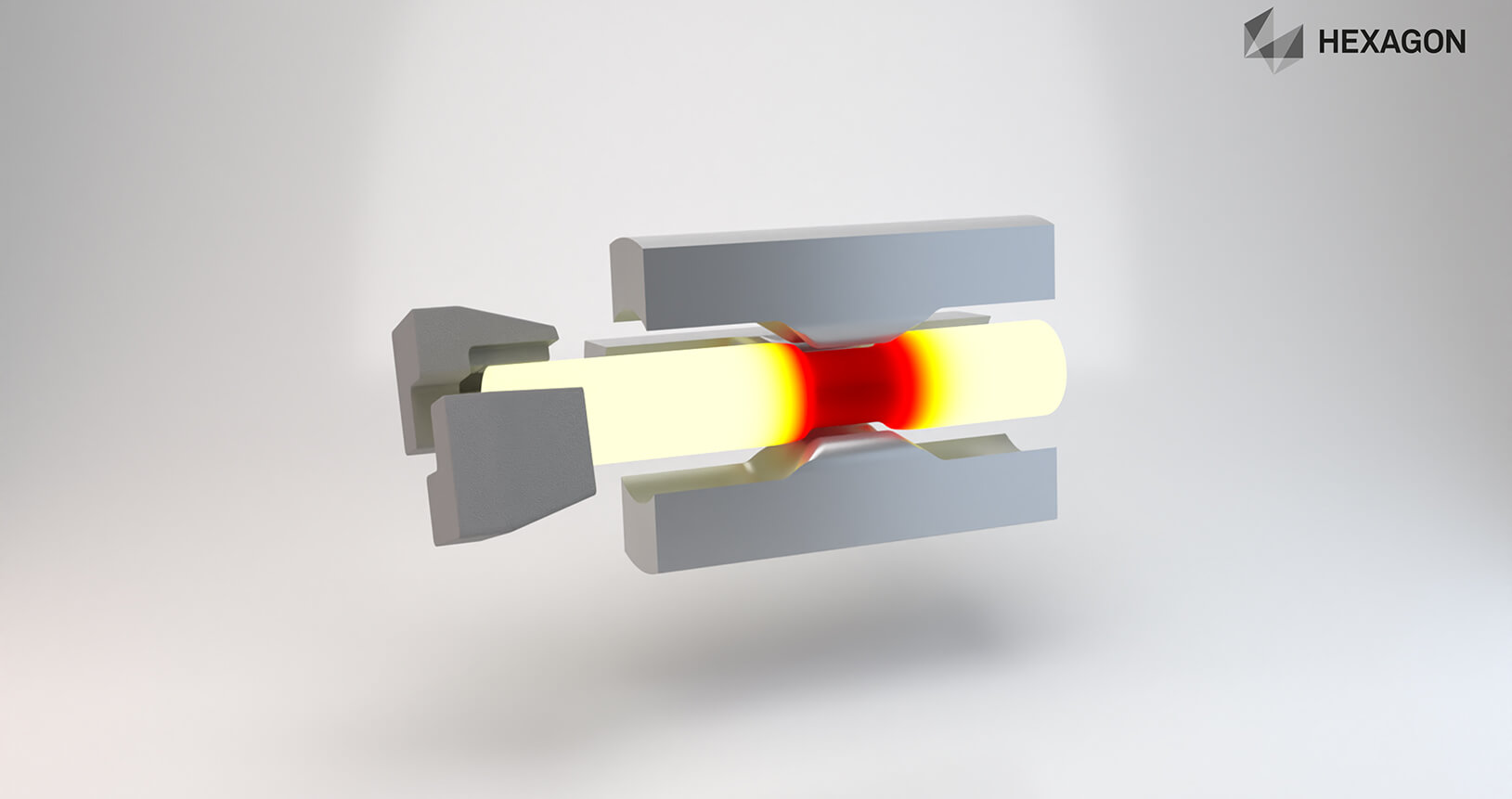

Resistance Spot Welding

A pressure welding process during which the sheets are pressed together locally with the help of fitted copper electrode welding guns. The electrical current between the weld guns causes a heating and melting of the joining partners, creating a small circular welded area between them.

Pressure Welding

Methods in which, metallic workpieces (mainly steel pieces) are temporarily Pressure welding stands for a group of joining processes in which components are joined by heating and compression. Heat can be generated either via current (resistance welding) or by using friction (friction welding) for the targeted improvement of the material’s properties.

Your benefits with Simufact Forming

Design and optimise your forming process:

- Determine the optimal number and sequence of stages and process window with minimal material usage while ensuring a robust manufacturing process.

- Identify and eliminate potential manufacturing defects.

- Optimise tool life.

Simplicity – No expert knowledge required as the software solution is designed to be user-friendly, intuitive and process-oriented.

Sustainability – Save material, time and money by replacing expensive and time-consuming physical tests with virtual tests.

Research Projects

Learn more about Simufact Forming

Related Articles

Technical Article

High temperature quality inspection

White Paper

Reducing costs through virtual simulation

Flyer