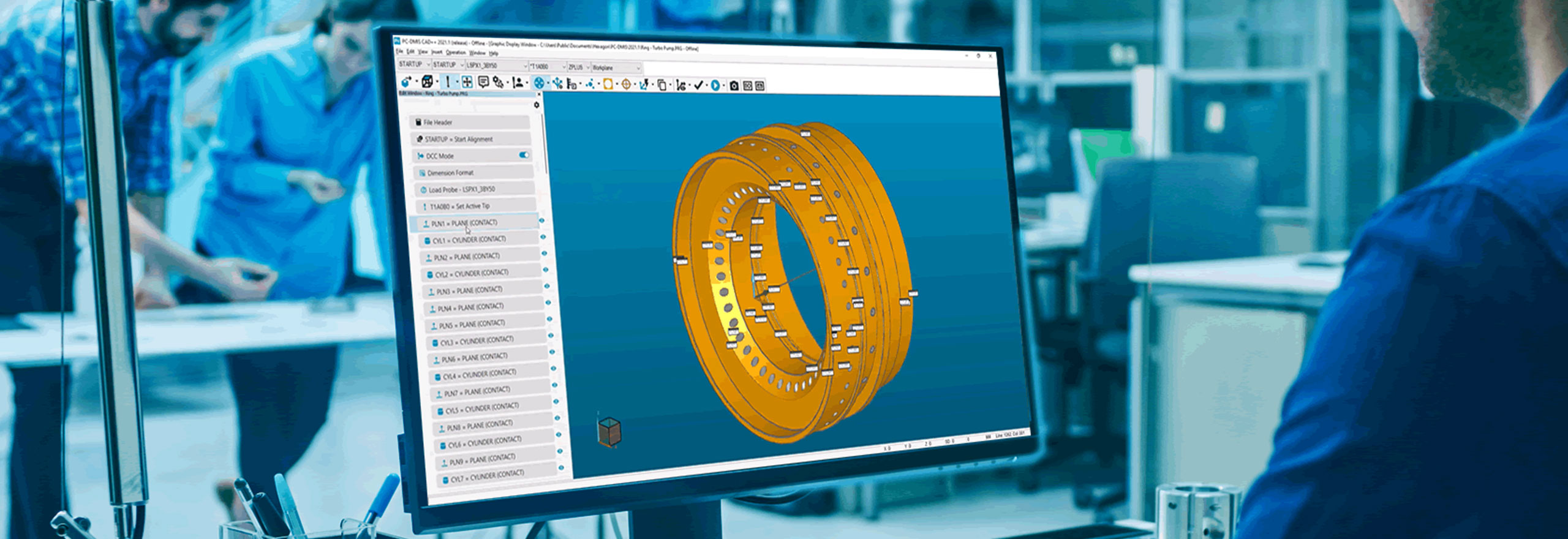

PC-DMIS 2023.1

Make the connection with PC-DMIS and drive quality data through your manufacturing workflow

Contact us

PC-DMIS 2023.1 is the beating heart within any manufacturing workflow, offering plug and play connectivity with Hexagon’s latest metrology hardware, plus integrations with a range of software applications to seamlessly move quality data from where it is created to where it needs to be. Additional features and improvements empower quality engineers to increase quality, efficiency and productivity. PC-DMIS 2023.1 is world leading metrology at the centre of in any smart manufacturing workflow.

Dynamic Inspection with Q-DAS

Q-DAS Statistical process control software monitors process stability based on measurement data from PC-DMIS. After analysis of measurement results, Q-DAS decides if all features need to be measured or a subset of features. Q-DAS instructs PC-DMIS to either run a full routine or a Dynamic Inspection mini-routine created using Feature Based Measurement in PC-DMIS.Dynamic Inspection requires no human intervention and shortens measurement cycle time based on statistical analysis for significant cost/time savings. This results is Increased throughput and reduced bottlenecks on the CMM.

Summary Mode Search & Filter

The new Summary Mode Search / Filter functionality allows the user to quickly find a command, feature or text string used in a measurement routine. For example, users can search and filter by feature name or dimension type. Results from search are also shown in the CAD window for faster identification and location. This saves time when creating or debugging routines or creating reports.Clearance cube improvements

An Improved User Interface makes it much easier to view and modify clearance cube settings for any feature. The new MoveSet command can be applied to MovePoints. This can be useful when measuring internal features – e.g. turn off Clearance Cube for a sequence of internal measurements to avoid the probe moving back to Clearance Cube after each feature.New Mesh Profiles

PC-DMIS now offers a range of convenient pre-set mesh profiles. Pre-defined mesh profiles take the “guess work” out of choosing which parameters to apply. Users can select a CoP and then choose a Mesh Profile – Fast/Normal/Detailed – or custom.Support for AT500 Tracker

PC-DMIS customers can now use the AT500 within the same, familiar environment they are used to. This maintains a consistent user experience with our world leading tracker devices. From reflector measurement at up to 160 metres from the tracker to simplified 6DoF probing functionality, the AT500 is ready for every manufacturing and assembly challenge, no matter the size or location.PC-DMIS support for HP-L-10.10 on Horizontal Arm CMMs

The HP-L-10.10 is now available for use with Horizontal Arm systems. When combined with PC-DMIS this creates a winning solution for fast, wide area scanning e.g. for use in automotive body and assembly.

PC-DMIS 2023.1 offers other new features and improvements, including:

Constructed Extracted Surface from CoP/Mesh Data

Segregate points from a COP or Mesh relating to one or more CAD surfaces. An easy, one step solution for isolating pointcloud / mesh data so that it can be identified as profile of a surface using either legacy dimensioning or the Geometric Tolerance Command.Geometric Tolerance Improved Support for Common Datums

Expanded support for the types of common datum that can be referenced in a Geometric Tolerance Command. Control Annotation Visibility in ViewSet

Turn individual colourmap annotations on and off before using ViewSet Image in Report – this allows the user to clean up the display or add focus to specific annotations.Add Descriptions to Geometric Tolerance Command

Users can now add a descriptions in the Geometric Tolerance dialog box via a new tab.PMI Selection – Feature Association

Allows users to link existing features from their measurement with the respective CAD surfaces. Delivers greater flexibility and an easier workflow when managing PMI data (GD&T Selection form CAD).Generate Multiple Report Formats (PDF, RTF, TXT)

Creates multiple file formats of a PC-DMIS report in one routine. This saves time and Services a range of different stakeholders requiring different format in a single process.Auto Feature – Measure Now Toggle Improvement

The behaviour of the "Measure Now" toggle in the Auto Feature dialog has been redesigned to prevent unanticipated machine moves which may have been left active by a previous user.Environment Configurator

Feature defines machine type, machine controller and non-contact probe with a simple UI setting. This avoids users needing to rename machine interface files in folderRobotic Automation – Measure a Static Point

Robotic Automation and PC-DMIS can now measures a static point within a robotic cell. This can be used for alignment and on features which are difficult to access for measurement.

Control Annotation Visibility in ViewSet

Turn individual colourmap annotations on and off before using ViewSet Image in Report – this allows the user to clean up the display or add focus to specific annotations.

HP-C-TS 5.10 CMM Compatibilities Extended

Now compatible with a broader range of new and existing machines. The compatibility was extended to Global and Gantry machines including RC1 controllers.

-

Technical data

-

Downloads