HxGN Digital Materials

We deliver material-focused solutions to empower product design with a predictive edge.

Revolutionise your engineering process with material-focused solutions

Reduce prototypes, accelerate product development and improve product performance with the Digital Materials suite.

Unlocking the power of materials

Design innovative materials through digital materials laboratory, manage material data for an easy access to material information, and use materials in multiscale simulations to unleash their full potential in product performance.

Artificial intelligence for materials laboratory

Hexagon’s digital transformation solutions in material engineering are driven by proficient expertise in material modelling combined with machine learning technologies. These solutions digitalise the development process and support the development of material digital twins, leading to a reduction in the time, cost and risk associated with experimental testing. Advanced, intelligent and scalable, these material digital twins help to accelerate the innovation of sustainable products, as well as set new standards of excellence.

Uncertainty quantification in multiscale modelling

A seamless journey in the digital era is ensured with a robust design that accounts for the uncertainties related to material properties and process simulation data. Hexagon’s materials solutions enable the autonomous processing of vast amounts of material data to explore the link between design and manufacturing. A reduced order model is trained to improve product design and efficiently assess the reliability of the studied structural analysis.

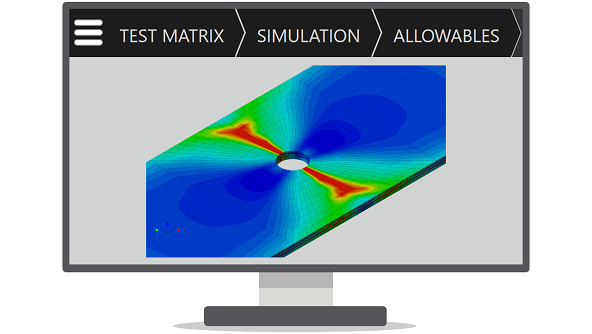

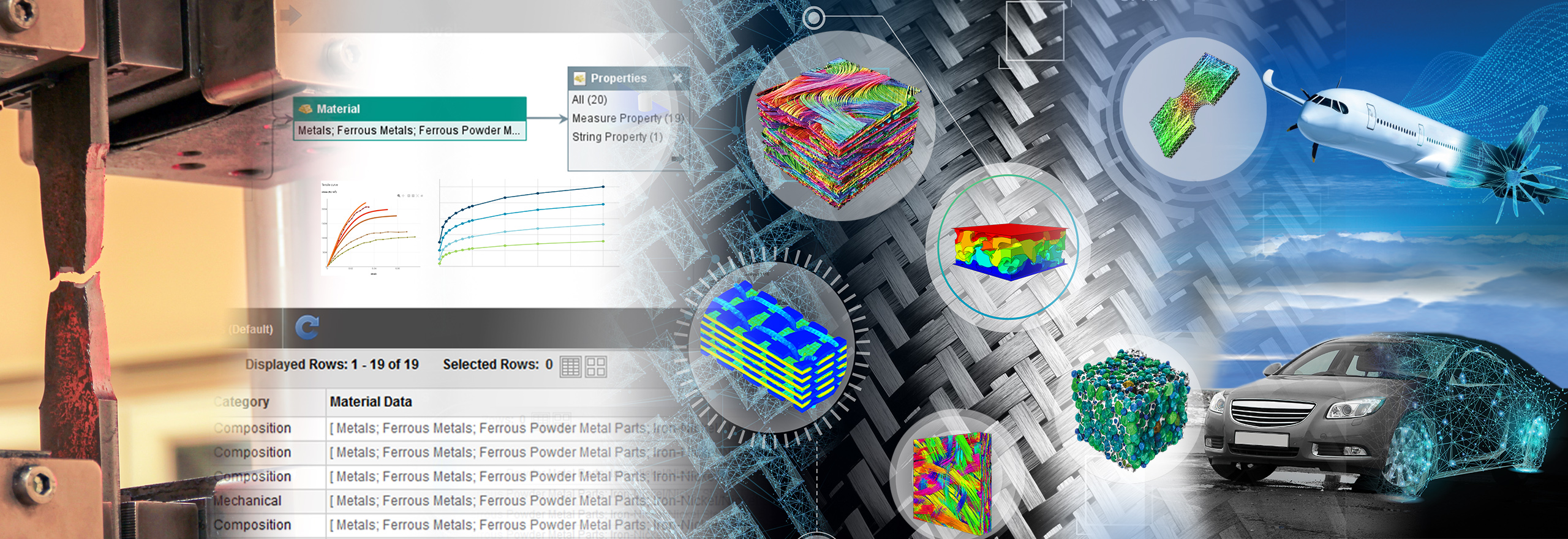

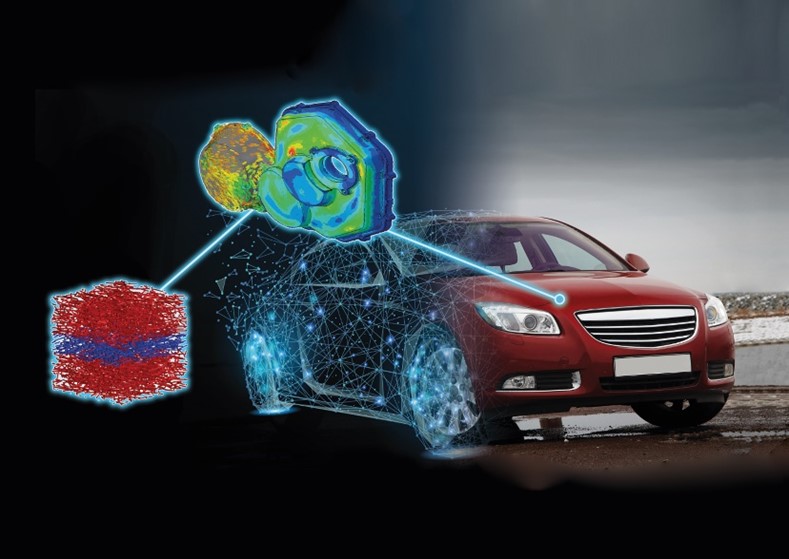

Innovative designs with multiscale simulations

True innovation in the connection of materials, manufacturing, and product design is required to transition towards a more sustainable future. Hexagon offers an end-to-end solution to perform integrated computational materials engineering (ICME) at hand. The multiscale simulations enrich CAE analyses to enable engineers to design lightweight components with no compromise on specifications and performance. It increases productivity and performance reliability while minimising weight, cost and time-to-market.

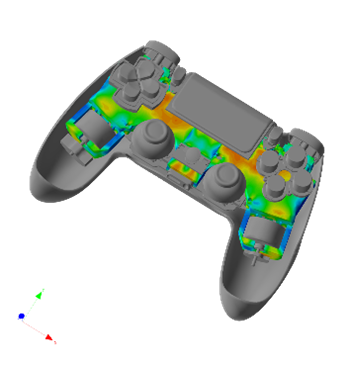

Smart manufacturing of sustainable products

Design and manufacturing innovation aids sustainable product development and supports a circular economy. Hexagon’s digital materials solutions reveal the effects of manufacturing processes and defects to enhance accuracy in part performance predictions, allowing engineers to optimise process variables, material selection and/or part design, while minimising physical trials and errors. For injection moulded parts like short fibre composites (SFRPs), simulation is a means to optimise gate location and positively affects efficiencies and part performance. For continuous fibre composites (CFRPs), simulating fibre and curing defects enable optimal material usage and accurate part performance predictions. For additive, process simulations help engineers identify the best printing strategy, minimising warpage and enabling first time right prints.

Access and exploit material data

Hexagon’s class-leading material databases provide access to commercial material databanks and advanced cloud technologies, ensuring Hexagon’s solution is both well-stocked with valuable data and well-equipped to handle both current and future needs. Based on limited experimental data, the tools allow easy and fast calibrations and creation of materials cards. Additionally, an established ecosystem of materials suppliers provides users with high-fidelity material cards ready to be used in CAE for a large number of applications.

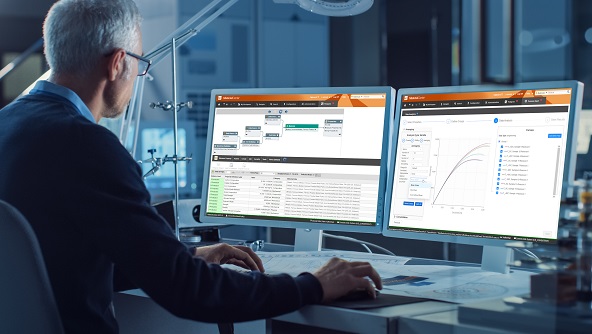

Organise, secure and trace material information

An enterprise-calibre data management solution ensures engineers have quick and easy access to critical materials information, thus maximising productivity and innovation. Interactive tools for searching, plotting, and viewing material data enable data-driven insights to make informed decisions. The single source of truth for the entire organisation integrates full-lifecycle data traceability, regulatory compliance and certification. Confidential data is secured with work requests and approval workflows, streamlining processes and improving efficiency.

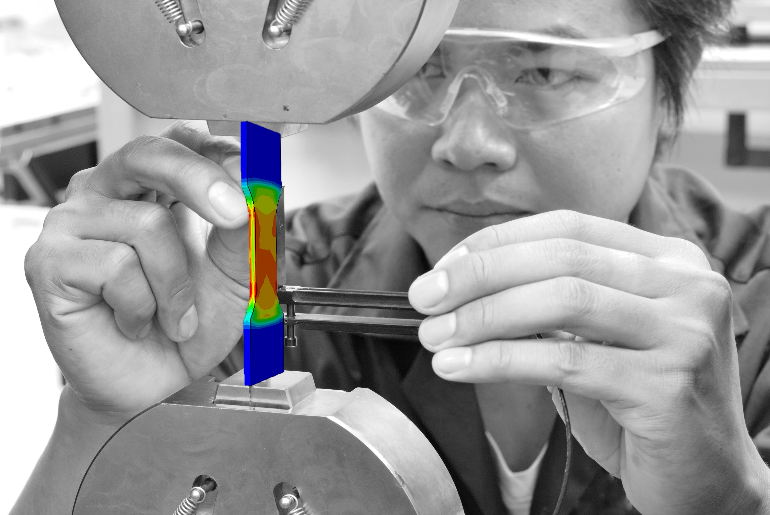

Digital Materials Laboratory

Material engineering is largely an empirical process, requiring accurate information, experimentation and optimisation. Hexagon’s class-leading virtual testing capabilities enable the creation of material digital twins, that empower scientists and engineers with an accurate understanding of complex material behaviours, including effects of defects. The efficient material screening and identification of promising candidates accelerates material innovations, while minimising experimental testing and saving development time and costs.

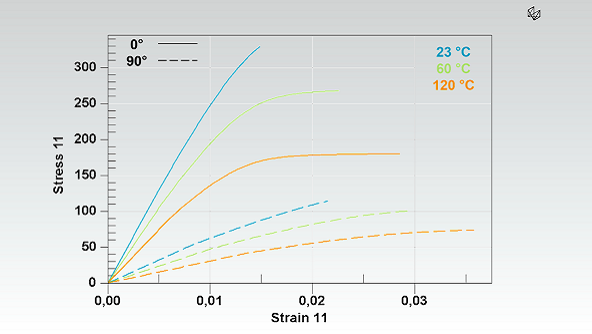

Material Data Enrichment

Leveraging technologies such as cloud computing, advanced material modelling and machine learning, Hexagon’s materials solutions enable material data generation to bridge the gaps where data are lacking. Material properties are efficiently enriched with accurate predictions, reducing the need for time-consuming and expensive experimental tests. These powerful and accessible engineering tools help improve productivity and accelerate the innovation of sustainable products.