Precision measurement of automotive transmission components

Achieve highly-accurate measurement of gear and gear housing components using the GLOBAL S CMM

Contact us

Automotive manufacturers are challenged to produce more components, faster, without compromising accuracy.

When met with the unique measurement challenges that come with transmission gear components, quality technicians and engineers need to be confident that their measurement results are highly accurate. The GLOBAL S coordinate measuring machine (CMM) with the Precision capability package from Hexagon Manufacturing Intelligence enables high accuracy measurements and provides greater visibility to the environmental conditions surrounding the CMM.

Handling complex geometries through software

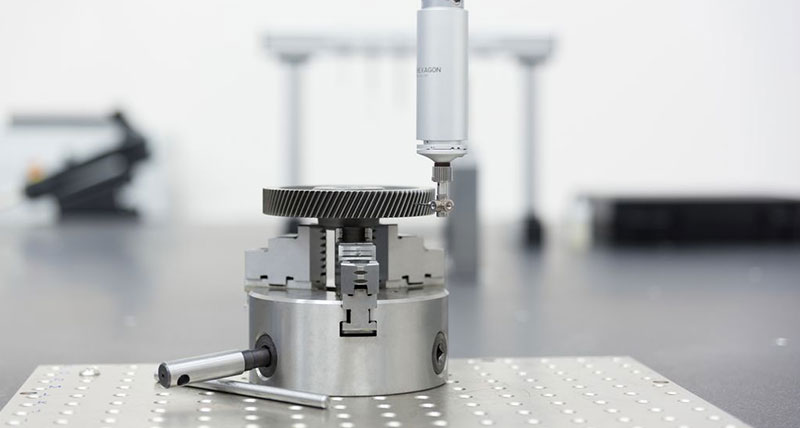

Gear manufacturers require special analysis of transmission gear components. The helical gear, for example, uses an angled design providing a much smoother and quieter operation. Because of this angled structure, precise measurement is required on the teeth of the gear.

Gears require multiple features to be validated for quality assurance because they must rotate or mesh with other gears. Today’s modern metrology software packages, like QUINDOS, offer the most precise analysis of gear characteristics like pitch error, involute and lead. Once measurement of the feature has been completed, the QUINDOS tool provides a report with deviations represented against a straight line. In addition to measuring known gears, the QUINDOS solution can measure unknown gears or even the tools used to cut the gear like the hob, broach, or shape cutter.

QUINDOS and PC-DMIS software offers manufacturers of gears and other components the flexibility to use one system for all components. The Measurement Strategies function in PC-DMIS uses built-in intelligence to ensure optimal measurement tools and parameters are used to match production processes and materials. The built in Geometric Dimensioning & Tolerancing (GD&T) selection tool provides the most up-to-date ASME and ISO standards to ensure features, dimensions and datum references are perfect every time.

Structured for precision measurement

The GLOBAL S CMM was designed to provide highly-accurate measurements. The aluminium frame provides a high strength to weight ratio, making it the ideal material for building extremely rigid yet lightweight structures.

The precision-machined dovetail guideways provide precise guidance along the entire travel path of the machine, while the TRICISION beam offers optimal stiffness-to-mass ratio of the bridge and, therefore, high accuracy and long-term stability.

GLOBAL S CMMs use advanced geometric compensation techniques to achieve the highest accuracy. The elastic joints and advanced firmware algorithms of the CMM’s patented Compass technology are able to absorb the vibrations generated during high-speed scanning measurements, ensuring the machine remains extremely precise.

Fixed for success

Collecting large amounts of points is crucial when precisely inspecting gear components. The use of scanning probes provides a larger collection of data, resulting in reliable measurement analysis.

The HP-S-X5 fixed scanning probe ensures high repeatability while decreasing measurement uncertainty. The sensor can perform single-point probing and continuous high-speed scanning of complex geometric parts. Due to its fixed head design the sensor is less prone to vibrations, ultimately increasing the accuracy of the system.

Take control of the CMM environment

When placing a CMM in a metrology lab or in an enclosure within the production environment, having control of the measurement environment is essential for obtaining accurate data. Any fluctuation in temperature, humidity or vibrations can impact measurement results. With PULSE, total monitoring of the environment is achieved. When an environmental event like temperature or humidity changes, or increased vibrations arise, PULSE sends an alert instantly, allowing the operator to get to the root cause faster, and helping manufacturers isolate the situation. With PULSE, operators can be confident that the measurement results are totally trustworthy and unaffected by environmental conditions.

With a combination of structural elements, high-precision sensors and an all-in-one software platform, the GLOBAL S offers a holistic solution for high-precision gear measurement.