IoT technology meets hi-precision

Zeno Tech - Japan

Contact us

Zeno Tech lays like a jewel in a nice and peaceful part of Okayama district in the southeast of Japan. Established in June 1974 as the mold department of Xeno Tool Co., Ltd., the company was later separated, becoming independent in 1991, and now specialises in powder metallurgy dies, precision cold forging dies and precision tools. Their in-house integrated production system, including various machining, heat treatment and finishing processes, enables the company making high-precision dies with high accuracy. The company’s demanding customers are acting mainly in the automotive, consumer electronics or agriculture machinery industries. Zeno Tech is also well-known for their complex shaped high precision, as for example in various parts of oil pumps, pulleys, clutches and transmissions.

The company not only provides their services to domestic customers but also to Japanese and local manufacturing companies based in areas such as China, southeast Asia and India. Their services are not limited to providing die and mold technology; they also offer support at the customer plants to resolve various problems in forging processes.

Zeno supports their customers’ needs for prototyping of new products with the use of two cold forging mechanical press machines available at their plant. They also support various types of product developments with the availability of equipment, such as a hydraulic unit, enclosed die sets or a heating furnace.

Already living Industry 4.0, Zeno’s work stations are connected by a network so that real-time information on area including order situation and work progress can be accessed at any time. This allows speedy responses to customer requests. And because Zeno’s dies are based on the true essence of “monozukuri”, they supply the dies to their customers with confidence. The IOT technology put in place across the entire group allows them to achieve the same Japanese quality even in overseas plants. But in order to supply high-quality dies Zeno also includes various types of high-precision measuring instruments in their quality assurance process.

As the parts and customer demands are getting more complex, the request for quality insurance has to be more flexible. “Measurements of hidden parts were not possible with our traditional metrology equipment. We knew about one of our suppliers offering a scanning solution. This was what we had in mind as a first solution” says Mr. Kawata.

The quality manager visited the JIMTOF trade show in 2016 and stopped by the large Hexagon Manufacturing Intelligence booth. Following a discussion with the Hexagon sales representative, Zeno very quickly had a good feeling about the various technologies and knowledge offered by the company.

“The Hexagon salesman quickly understood our needs and contacted us back to make a quote for an PrimeScan within a very short time. Your competitor did not show the same level of skill to explain the technology of his product. They were also very slow with their answer but also not active. This is not what we are expecting from our suppliers.”

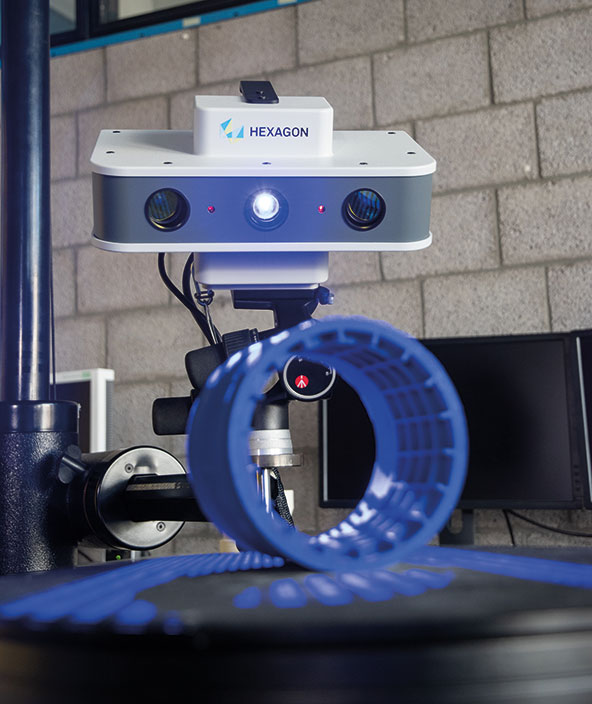

Zeno opted for two PrimeScan 3D scanning units configured according to their needs: one with a 50-millimetre field of view for small parts and the other one with a 125-millimetre field of view for larger pieces. Both are used in a fixed layout including a stand for the scanner and a turntable for the part.

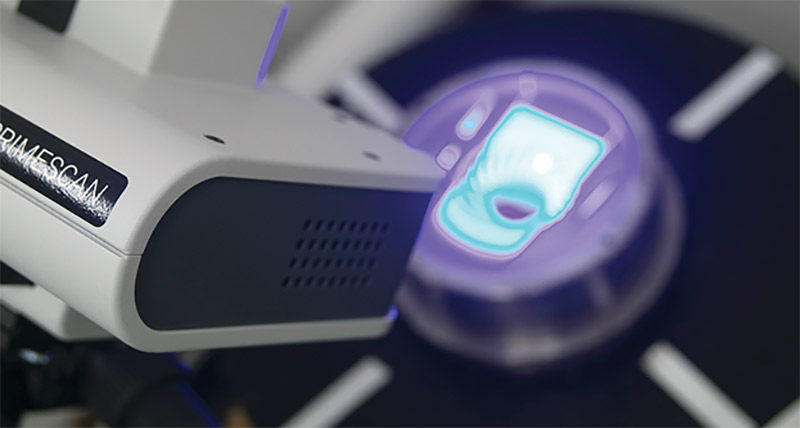

The high luminous power and the best projection quality delivered by the fringe projection technology of the PrimeScan allows them to complete their quality inspection and ensure a complete check of all parts before shipping to their customers. The devices’ high-resolution sensor technology offers the maximum level of detail and allows them to no longer have complains. If they find mistakes, those can be immediately corrected in the three-dimensional models.

The Okayama company also integrated the OptoCat software, using its custom algorithms for the fast creation of highly precise point clouds to use in their measurement processes. They appreciate how easy the software is and how fast it was to learn to use. “Everyone can use it. It’s very intuitive and very nice to use,” concludes Kawata.

The company not only provides their services to domestic customers but also to Japanese and local manufacturing companies based in areas such as China, southeast Asia and India. Their services are not limited to providing die and mold technology; they also offer support at the customer plants to resolve various problems in forging processes.

Zeno supports their customers’ needs for prototyping of new products with the use of two cold forging mechanical press machines available at their plant. They also support various types of product developments with the availability of equipment, such as a hydraulic unit, enclosed die sets or a heating furnace.

Already living Industry 4.0, Zeno’s work stations are connected by a network so that real-time information on area including order situation and work progress can be accessed at any time. This allows speedy responses to customer requests. And because Zeno’s dies are based on the true essence of “monozukuri”, they supply the dies to their customers with confidence. The IOT technology put in place across the entire group allows them to achieve the same Japanese quality even in overseas plants. But in order to supply high-quality dies Zeno also includes various types of high-precision measuring instruments in their quality assurance process.

As the parts and customer demands are getting more complex, the request for quality insurance has to be more flexible. “Measurements of hidden parts were not possible with our traditional metrology equipment. We knew about one of our suppliers offering a scanning solution. This was what we had in mind as a first solution” says Mr. Kawata.

The quality manager visited the JIMTOF trade show in 2016 and stopped by the large Hexagon Manufacturing Intelligence booth. Following a discussion with the Hexagon sales representative, Zeno very quickly had a good feeling about the various technologies and knowledge offered by the company.

“The Hexagon salesman quickly understood our needs and contacted us back to make a quote for an PrimeScan within a very short time. Your competitor did not show the same level of skill to explain the technology of his product. They were also very slow with their answer but also not active. This is not what we are expecting from our suppliers.”

Zeno opted for two PrimeScan 3D scanning units configured according to their needs: one with a 50-millimetre field of view for small parts and the other one with a 125-millimetre field of view for larger pieces. Both are used in a fixed layout including a stand for the scanner and a turntable for the part.

The high luminous power and the best projection quality delivered by the fringe projection technology of the PrimeScan allows them to complete their quality inspection and ensure a complete check of all parts before shipping to their customers. The devices’ high-resolution sensor technology offers the maximum level of detail and allows them to no longer have complains. If they find mistakes, those can be immediately corrected in the three-dimensional models.

We were very pleased by our first contact with Hexagon and it is still going on like that.

Zeno’s customers were very receptive to the new quality reports based on the photogrammetry technology and have even shown some interest in the technology. “Getting a new and modern technology gives us a status of leader that we can only appreciate. We will soon update all our documentation with the new scanners.”The Okayama company also integrated the OptoCat software, using its custom algorithms for the fast creation of highly precise point clouds to use in their measurement processes. They appreciate how easy the software is and how fast it was to learn to use. “Everyone can use it. It’s very intuitive and very nice to use,” concludes Kawata.