Automated perfection in automotive

A comprehensive automated inspection system based on laser tracker measurement and advanced 3D scanning is just the beginning at Tofaş

Contact us

Tofaş is a Turkish automotive manufacturer established in 1968 in Bursa, where the company’s manufacturing plant is located. The company manufactures both passenger cars and light commercial vehicles, and is by now one of the largest automakers in the sector, with some 7000 employees and an annual production capacity of 450 000 vehicles.

Tofaş manufactures Fiat Egea sedan, hatchback, and station wagon models at its Bursa plant. Marketed under different brand and model names in different parts of the world, Tofaş’s Egea line is sold as the Fiat Tipo in Europe and as the Dodge Neon in Mexico. Besides manufacturing for Fiat, Fiat Professional and RAM under its new Doblò project, Tofaş is also a distributor, handling the domestic sales of six brands (Fiat, Fiat Professional, Alfa Romeo, Jeep, Maserati, Ferrari) in Turkey. Tofaş exported 118 000 units to 80 countries in 2020 and fulfils 19 percent of total automotive production in Turkey.

The main business of the team in Bursa is currently production of the Fiat Egea passenger car model, along with the Fiat Doblò commercial vehicle, both in short- and long-wheel-based versions. They currently produce approximately 1000 vehicles per day, which requires a dedicated measurement centre team tasked with maintaining stable geometries in their processes and products.

The Tofaş measurement team uses a variety of Hexagon metrology equipment, including 3 Global model CMM systems. These systems were installed in 2016, paired with Hexagon’s PC-DMIS inspection software, and are particularly used to assess the quality of small parts brought in from third-party suppliers. The team also has two Bravo HP CMM systems, one with four arms and one with two. The former of these is used as part of a comprehensive body-in-white diagnosis system, while the latter is used for statistical process control measurements for the Fiat Egea passenger car models.

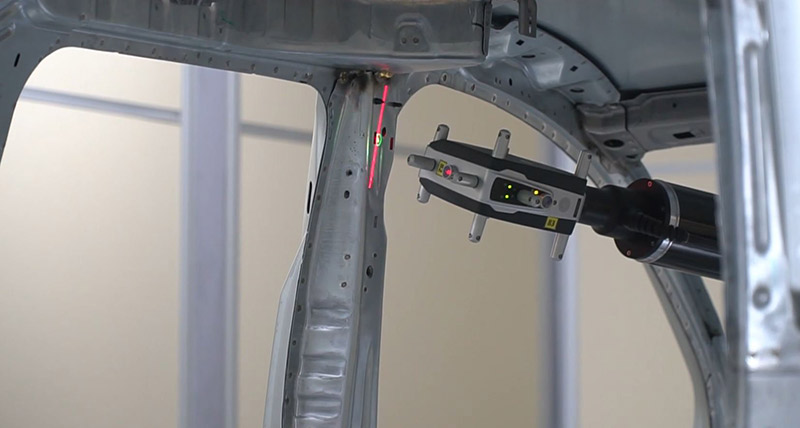

Figure 1. The Leica T-Scan 5 has the high-dynamic scanning capabilities to power the new fully automated inspection cell at Tofaş.

While these systems have achieved excellent results, the Tofaş measurement team has begun the transition to working with scanning systems, in order to capture some of the wide-ranging benefits of non-contact measurement processes. This revolution was begun with the Hexagon white light system installed for closures inspection, also installed in 2016 and powered by the CoreView software.

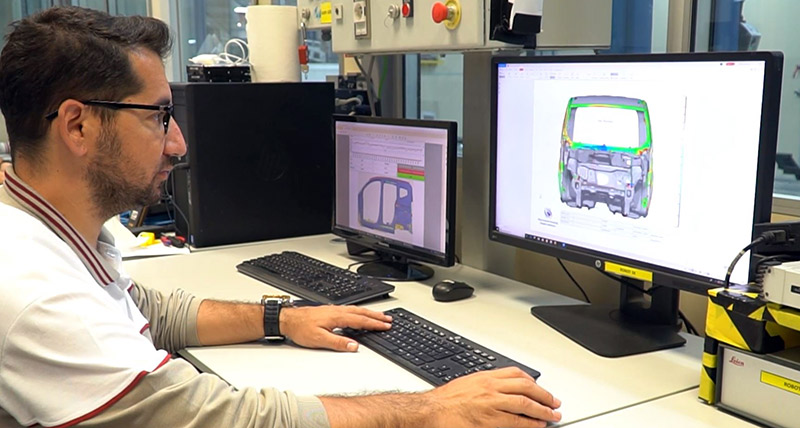

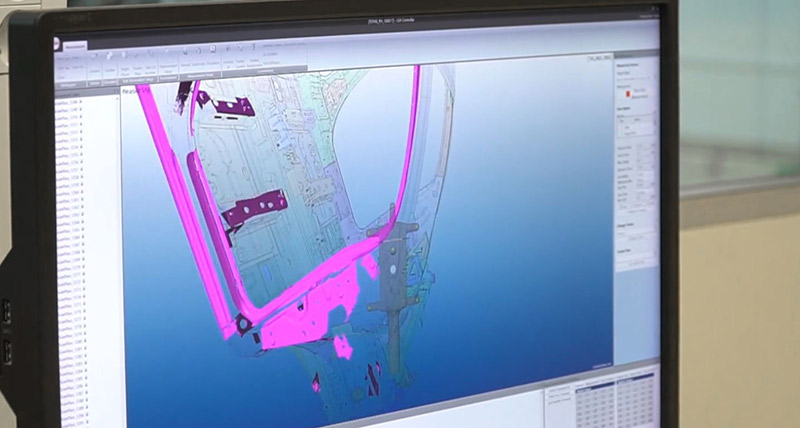

Figure 2. Reporting is fast and clear using the PolyWorks platform.

The team’s most recent metrology installation is a fully automated inspection cell powered by Absolute Tracker and Leica T-Scan 5 measurement technology, which is used to measure the commercial vehicles in production at Bursa. Established in 2020 and powered by PolyWorks inspection software, the cell has proven to be a success for the team, and looks set to be only the beginning for Tofaş in terms of investment in automated inspection solutions.

“Instead of CMM we are using scanning technology, and there are so many advantages,” says Utku Erdem Kaynar, Metrology Lab Leader for Tofaş in Bursa. “We can see so many areas of the vehicles or parts with this system.”

“We are especially measuring body in white and closures with these devices, with features such as surfaces, trimlines, nuts, slots, holes – all kinds of parts related to body in white can be easily and reliably measured with these systems.”

“Regarding tolerances, of course it depends on the measurement area, but we are talking about sheet metal, so our minimum tolerance is plus or minus 0.4 millimetres, and maximum tolerances are plus or minus 2 millimetres. Of course, this changes depending on the criticality of the area.”

Figure 3. Full vehicle scan data can be collected incredibly quickly and reviewed in real time.

“We are working very closely with Hexagon Turkey,” explains Recep Boylu, Measurement Centre Administrator at Tofaş. “They have very capable people who have a talent for solving issues and creating solutions according to our problems. And of course, they have the agility to perform maintenance activities as needed without delay, minimising our downtime.”

Figure 4. Reporting is fast and clear using the PolyWorks platform.

“Now, across both CMMs and scanning technologies, we are using only Hexagon products. Previously we have used several different machines from other metrology providers, but due problems with after-sales support and maintenance issues we have eliminated these and are now focused on only applying Hexagon’s solutions and receiving support from their excellent team.”

The Leica T-Scan 5 covered in this case study have since been discontinued. Please visit [Absolute Scanner] for details of our current options in this product category.