Inspection of rolling stands and rolled products

Dedicated tools to measure hot and cold profiles and roll wear

Steel

Portable profile measurement in rolling mills

Ready to learn more?

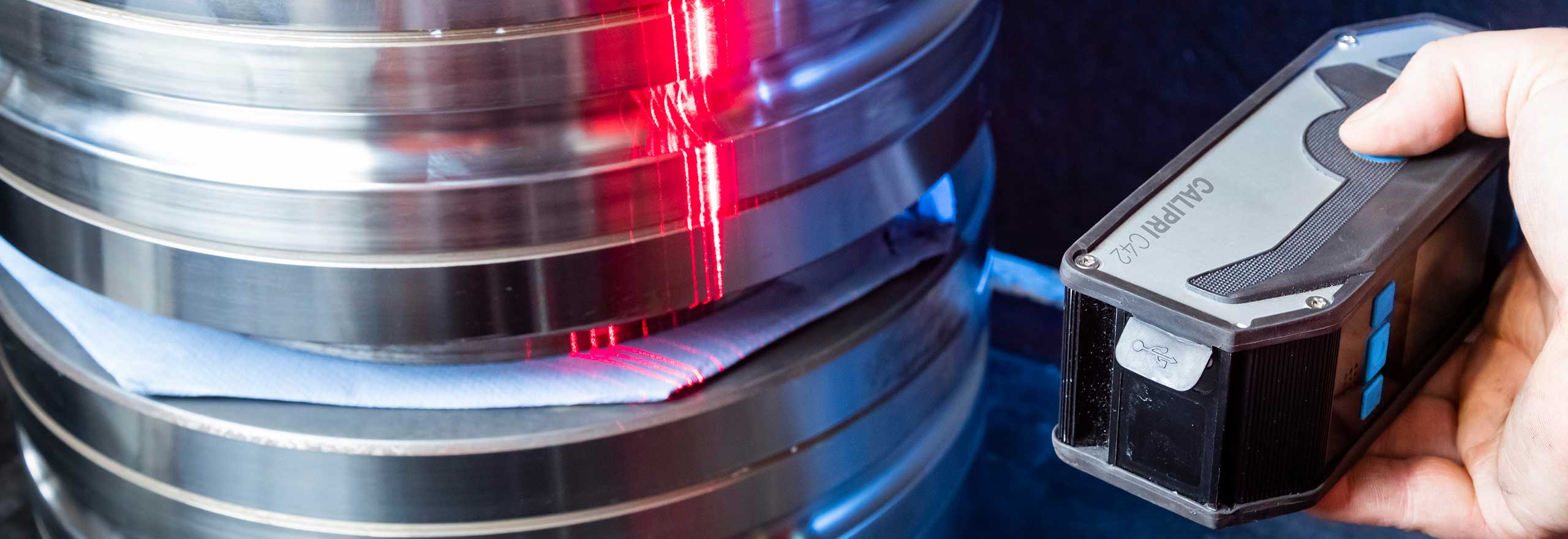

Rising quality standards in the steel industry requires highly accurate inspection and full documentation right from the source for rolled product production. To achieve production quality standards the dimensional accuracy must be monitored during the entire steel manufacturing process. Modern quality control concepts for the steel industry requires, next to continuous measuring of the final product, systems for spot checks of profile shape. These measuring systems must work quickly, precisely and be failsafe. With the CALIPRI steel measurement solution, Hexagon provides specialised tools to measure the wear condition of the roll stands, as well as the product cross-section between the stands. All systems are based on non-contact measurement technology and obtain highly accurate measurement results.

The CALIPRI system helps rolling mill operators produce the highest quality steel profiles for a variety of industries including rail, automotive, heavy machinery and construction.