SmartUQ - predictive analytics software

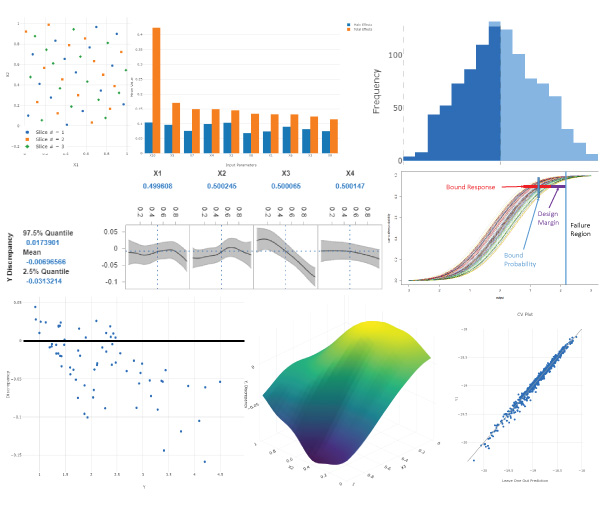

SmartUQ is a powerful predictive analytics and uncertainty quantification (UQ) software tool.

Find out more

Smart UQ was built from the ground up to solve some of the most challenging analytics problems faced by manufacturing companies. In industries like automotive, aerospace & defence, turbomachinery, heavy equipment, medical devices, semiconductors, energy, oil & gas, heating, ventilation, air conditioning and consumer products, SmartUQ software has saved our customers millions of dollars and thousands of hours of work.

Applications:

- Acceleration of simulation efforts

- Testing and evaluation planning

- Uncertainty analysis

- Optimisation of decision-making under uncertainty

- Real system applications

- Model calibration and validation

- Digital twins/thread

- Additive manufacturing

- Root cause analysis

Easy-to-use software:

- User-friendly GUI — Powerful yet intuitive, SmartUQ is designed for engineers and data scientists alike. SmartUQ's clean, straightforward user interface, including software wizards, makes performing complex analyses easier than ever before.

- Integration — Analytics software is only as powerful as it is compatible with other systems. SmartUQ has built-in integrations with MSC Software products like Adams, Digimat, and Nastran. Additionally, with SmartUQ's application programming interface (API), you can seamlessly integrate SmartUQ tools into your workflow. SmartUQ's API significantly reduces time spent on performing analyses while still providing the full benefits of its GUI.

- Automated predictive modelling — With an existing data set or a connected simulation model, SmartUQ runs, builds and compares predictive models until it meets your accuracy requirements.

Benefits:

Save Time

- Reduce duration of simulation and testing.

- Catch problems early, reducing development time.

- Prevent unnecessary design iterations.

Decrease Costs

- Increase utility of simulations.

- Fewer tests and prototypes.

- Reduce cost associated with unexpected failures.

Improve Quality and Reduce Risk

- Validate that the simulation agrees with reality.

- Maximise product reliability and durability.

- Meet oversight requirements (FAA, FDA, DoD).

Capabilities:

- Modern design of experiment tools designed to efficiently collect data from simulation, physical testing, or digital twins.

- Unique data sampling tools for subsampling or dividing large data sets into evenly distributed batches to build large-scale machine learning models.

- Flexible predictive modelling and machine learning tools to cover a wide range of scenarios including high dimensional problems, large sample sizes, spatial data, and functional/transient responses.

- Statistical calibration tools to determine model calibration parameters even with limited simulation and test data, and provide model discrepancy to improve simulation and perform model validation.

- Inverse Analysis tool to calculate the probability distribution of inputs based on a set of outputs from a system, helping to verify hard-to-measure system properties.

- Sensitivity analysis library to rapidly determine which factors have a relatively low or high impact on the outputs, allowing engineers to focus efforts appropriately.

- Optimisation library handles multiple objectives and accommodates very large numbers of inputs.

Modules available on MSCOneXT

- SmartUQ GUI

- SmartUQ Python API