Speed and simplicity meet rigour and precision

GRADEL Sàrl - Ellange, Luxembourg

Contact us

Founded in Luxembourg in 1965, GRADEL has experienced remarkable growth and currently employs 60 people in the Grand Duchy of Luxembourg. It is active in the project management, design and assembly of special machines for industry, with a particular focus on the nuclear and space sectors, as well as in the production of sputtering targets for the glass industry, using a patented process.

Throughout its history, the Luxembourger company has built up an international reputation thanks to its expertise in special equipment dedicated to maintenance and dismantling in the nuclear sector. The company has never ceased to innovate and diversify, demonstrated by their presence in the aerospace sector since 2008.

GRADEL’s field of expertise requires impeccable traceability and quality. For example, the company has equipped itself with an X-ray fluorescence analyser (XRF), a very important technical device used to ensure their metal grades meet the required standards. This is especially important in the nuclear sector, which requires very detailed certifications.

“Some projects require the input and management of thousands of parts in a few weeks,” explains Robert Di Pelino, Supply Chain Manager at GRADEL. “We therefore have to be extremely rigorous with our suppliers and our large network of subcontractors.”

This demand for the highest quality products is therefore reflected in the range of three-dimensional inspections performed when parts are received. “For a long time these were carried out in the traditional way using callipers, micrometers, roughness meters or other manual measuring instruments,” says Di Pelino. “An old three-dimensional machine was also available to us in the past, but it proved to be too slow and complex for the expected use. However, the need to check dimensions against precise drawings in order to obtain detailed confirmation was crucial. We therefore needed a tool that would allow us to quickly and simply check the received parts accurately.”

GRADEL therefore started from scratch in the search for a tool that could correspond precisely to its needs, in line with the following key constraints: size, degree of accuracy, flexibility, training needs for non-metrologists and, of course, budget.

Collected measurement data is used for defined quality procedures: the certification of items and assemblies that make up GRADEL’s equipment and projects, and the functional and dimensional verification of other applied post-test components. It was also important to the company to find a solution that reflected the latest innovations on the metrology market.

We needed a tool to be able to quickly and simply check the parts we receive in a precise manner

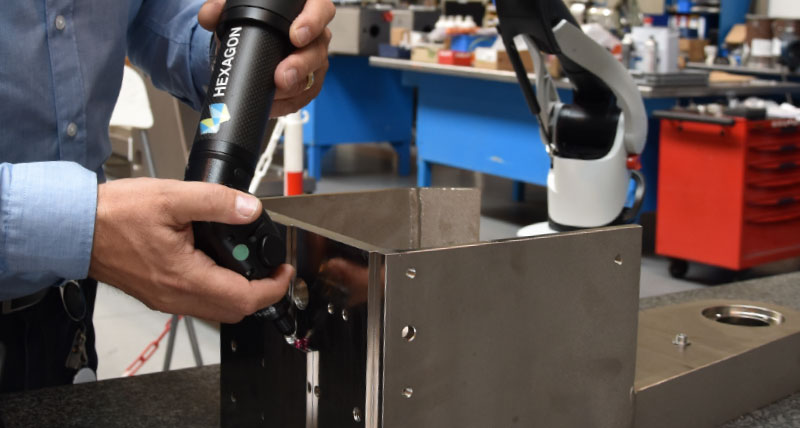

“The choice of a measuring arm quickly proved to be the best solution for our needs, and also offered portability and flexibility. An offer of a second-hand measuring arm from one of our service providers was financially attractive but its durability in terms of after-sales service and spare parts was not guaranteed. We therefore turned to Hexagon for a 2.5 metre, 6-axis Absolute Arm 85 Series arm with PC-DMIS software,” explains Di Pelino.

As some of GRADEL’s sub-contractors were already using PC-DMIS, the company was able to reuse the files in an optimal way by using new options such as adding items, changing the layout or customising reports for its customers. The software handles CAD imports and quality reports simply and efficiently.

“The measurements carried out with the Absolute Arm are very varied, as are our projects: from welded and precision machined chassis-mechanics to various manufactured parts and complementary equipment. The tolerances are relative to the dimensions measured with the arm, but in most cases are in the order of +/- 0.030 to 0.100 millimetres”.

“The measurements carried out with the Absolute Arm are very varied, as are our projects: from welded and precision machined chassis-mechanics to various manufactured parts and complementary equipment. The tolerances are relative to the dimensions measured with the arm, but in most cases are in the order of +/- 0.030 to 0.100 millimetres”.

“The arm gives us greater flexibility and autonomy for our control processes, as well as greater capacity and ease for certain demanding and complex measurements. However, we continue to use external measurement services, such as laser trackers, for larger projects.”

The fact that five people have been trained on the arm – three in charge of receiving the parts and two assembly technicians who travel to customer sites – reflects GRADEL’s highly flexible “turnkey” solutions, which including pre-studies, quotations, assessments, development, sourcing, assembly, complete on-site tests, preparation of quality documents, training and the provision of an on-site intervention team for dedicated operations. By handling projects from A to Z, GRADEL not only focuses on service, but also on the people who support its services.