Production

Power to make the impossible and take it to market.

Contact us

Push production to the limits. Make what they said was unmakeable. Bring innovations to life in incredible new ways. See design intent through into market ready products. Our solutions empower makers to turn imagination into reality.

Spanning machining, forming, casting, moulding, joining, 3D printing, or a combination of multiple processes – the production floor is where components take shape. Production is where product quality is set in stone, metal, wood or composite and the pursuit of manufacturing ‘right first time’ is the highest priority. It’s the manufacturing process phase where productivity really matters – efficiency and throughput are essential to

remain competitive – costs must be controlled and downtime avoided. This is where you need design intent to be maintained through the production cycle.

Manufacturing quality products requires production software designed for the task at hand. Our production software portfolio includes specialised packages to generate, manage and optimise toolpaths in a range of industry and material applications. It empowers makers to address the requirements of the tooling, production engineering, sheet metal, metal fabrication, stone and woodworking sectors. Despite these diverse applications, our production software solutions share a common focus on driving manufacturing efficiencies and adding value to operations.

Hexagon empowers production engineers and technicians with a large range of computer-aided design and computer-aided manufacturing (CAD CAM) software that enables users to produce quality parts. Quality in the production phase ensures that design intent is maintained throughout the production process and into service life, managing costs and improving productivity. Our CAD CAM solutions are used by manufacturers around the world to program CNC machine tools and execute manufacturing processes as designed, whether it’s for producing prototypes, finished products or production runs.

Hexagon CAD CAM software not only gives customers confidence that their manufacturing processes are producing quality, but also delivers a platform for users to maximise their potential. Our products are designed for flexibility and can be integrated consultatively to give customers the right solution for their needs.

Hexagon’s production software tools embrace manufacturing excellence, improve process efficiencies, and empower makers to ensure reliable delivery of quality products.

Spanning machining, forming, casting, moulding, joining, 3D printing, or a combination of multiple processes – the production floor is where components take shape. Production is where product quality is set in stone, metal, wood or composite and the pursuit of manufacturing ‘right first time’ is the highest priority. It’s the manufacturing process phase where productivity really matters – efficiency and throughput are essential to

remain competitive – costs must be controlled and downtime avoided. This is where you need design intent to be maintained through the production cycle.

Manufacturing quality products requires production software designed for the task at hand. Our production software portfolio includes specialised packages to generate, manage and optimise toolpaths in a range of industry and material applications. It empowers makers to address the requirements of the tooling, production engineering, sheet metal, metal fabrication, stone and woodworking sectors. Despite these diverse applications, our production software solutions share a common focus on driving manufacturing efficiencies and adding value to operations.

Hexagon empowers production engineers and technicians with a large range of computer-aided design and computer-aided manufacturing (CAD CAM) software that enables users to produce quality parts. Quality in the production phase ensures that design intent is maintained throughout the production process and into service life, managing costs and improving productivity. Our CAD CAM solutions are used by manufacturers around the world to program CNC machine tools and execute manufacturing processes as designed, whether it’s for producing prototypes, finished products or production runs.

Hexagon CAD CAM software not only gives customers confidence that their manufacturing processes are producing quality, but also delivers a platform for users to maximise their potential. Our products are designed for flexibility and can be integrated consultatively to give customers the right solution for their needs.

Hexagon’s production software tools embrace manufacturing excellence, improve process efficiencies, and empower makers to ensure reliable delivery of quality products.

Design and Engineering

Embed quality into product design and engineering to ensure component manufacturability and downstream production productivity.

Produce Quality

See how CAM-programmed machining technologies optimised quality and throughput for Audi toolmaking, reducing processing times for pre-finishing pressing tools by up to 30%.

Metrology

Capture real-world quality data for measurement, positioning and inspection, and use actionable information gained by analysing the results to improve manufacturing processes.

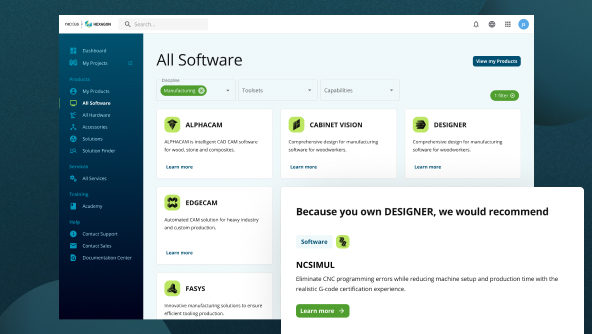

Computer-Aided Manufacturing (CAD CAM Software)

Hexagon’s CAD CAM (computer-aided design and computer-aided manufacturing) software portfolio enables manufacturers to generate, manage and optimise CNC machining toolpaths for more efficient production processes.

Empower your team with Nexus

Access eLearning, download software, and sign-up for training courses on the platform.