NCSIMUL Tool

The smart, high-performance CNC machining verification / simulation software experience.

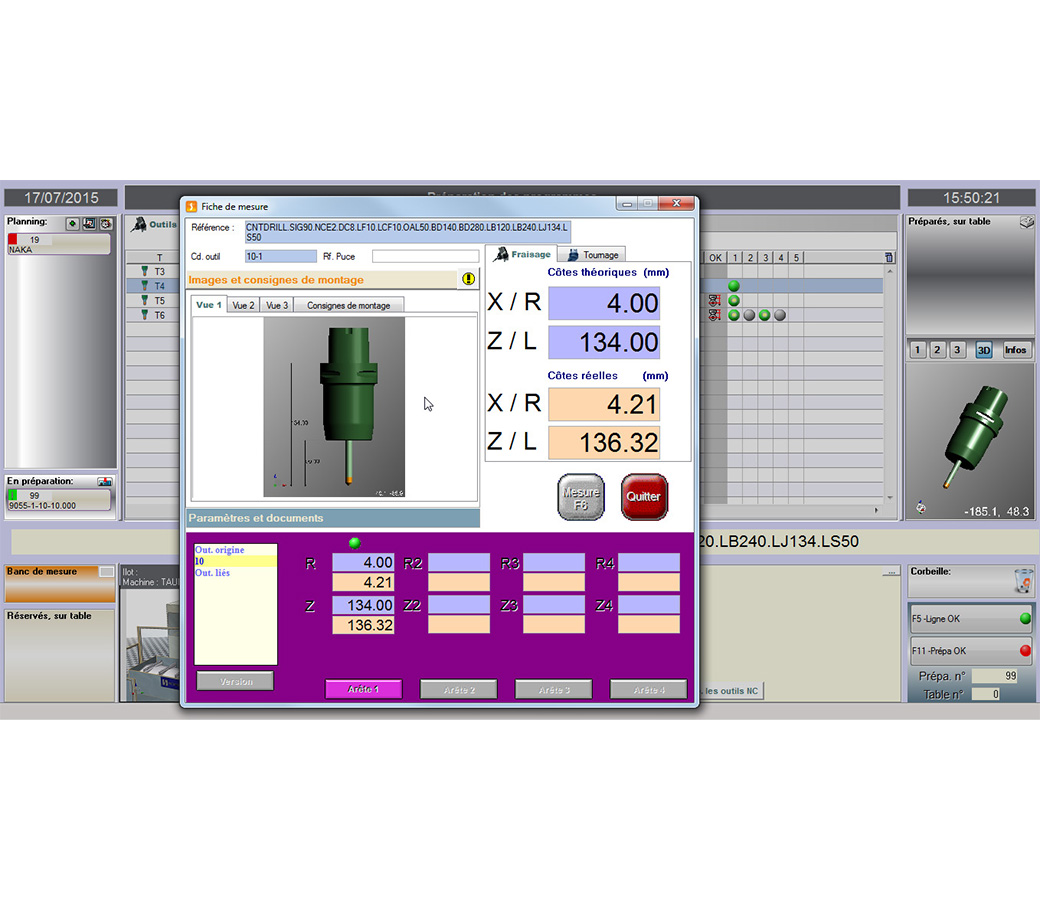

Cutting tool management

NCSIMUL Tool allows you to manage your tool flow, scheduling, and inventory of cutting tools.

Product capabilities

Features at a glance:

You operate at least 5 machining centres. You are looking for ways to respond even faster to demand, keep control of costs and improve the management of your cutting tools :

Challenges:

- You're scratching your head for ways to make savings on your NC machines

- You keep entering the same tool data into multiple programs

- The tools you see in theory don't match the tools in the workshop

- You are constantly looking for missing tools when it's time to start production

- You are not making the most of the cutting knowhow in your company

- Your tool turnaround time is less than optimal

Benefits:

- Rationalize your tool inventory and turnaround time

- Integrate your tools into your global production process

- 95% of tool uptime while you prepare

- 50% time savings on tool preparation

- 30% less tools in inventory

- 15% less value wasted on unused inventory

- 0% dead or unsupported tools

- Global management of the tool flow: elements, assemblies, test and inspection systems, 3D CAM models, inventory, stats, supplier data, documents and cutting parameters…

- Single repository for nominal and physical tools built into the global production process.

- Analysis and rewrite function for the ISO program before loading on to the machine: renumber calls, write compensation and special codes for tool measurement on the machine.

- Scheduling of tool preparation and automatic renewal based on inventory / production flows.

- Control and/or interface with automated controllers, measurement bench, laser measurers, etc.

- Interfaced with leading CAD/CAM software: CATIA, Edgecam , Esprit, NX, TopSolid CAM, etc.

"With NCSIMUL TOOL we have succeeded in reducing our cutting tool costs while optimizing preparation efficiency and making our machine-tools more productive."

Franck COPIN

CAM/Process engineering Manager

AREVA