NCSIMUL

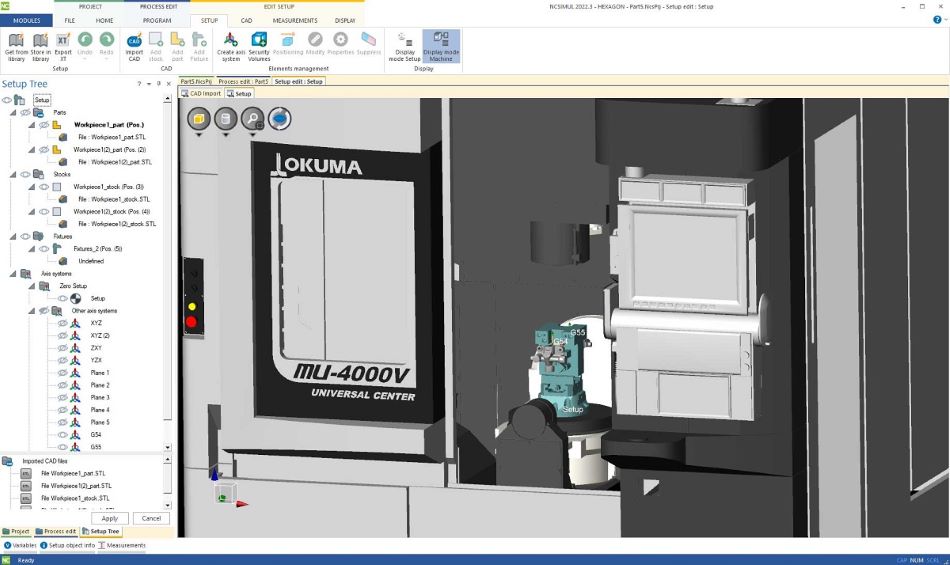

Several new enhancements have been made in version 2022.3 of NCSIMUL.

NCSIMUL - What's new

Watch the videos to discover our new functionality.

Here are some of the major highlights:

-

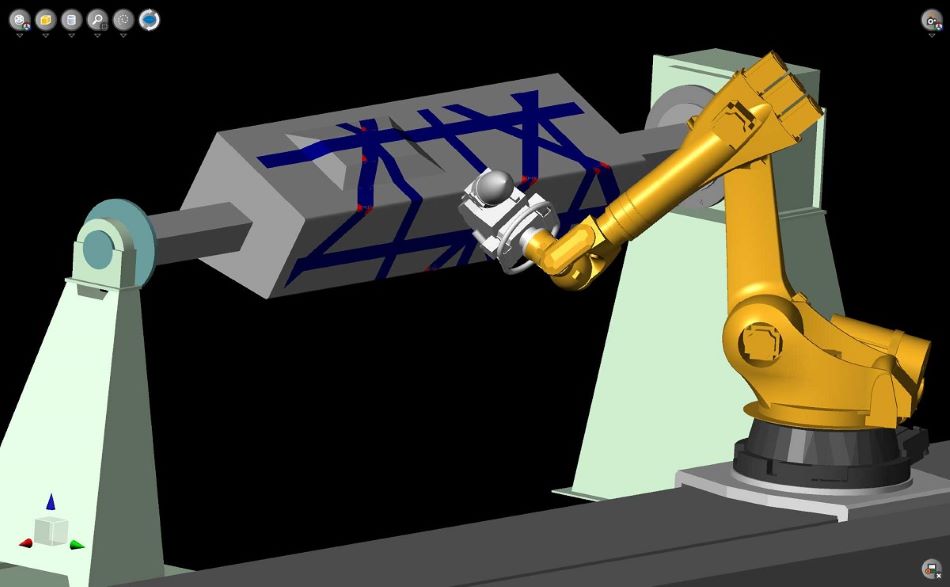

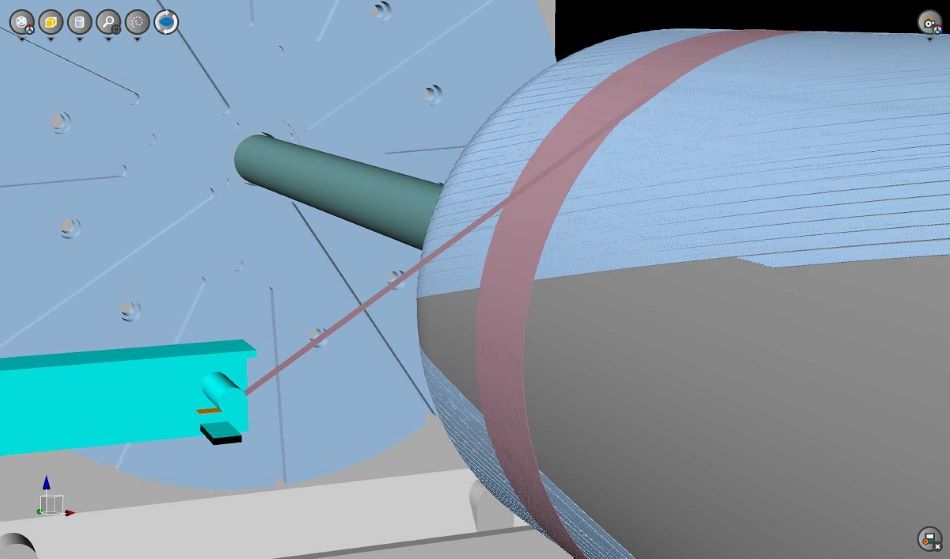

AFP, ATL, and CFW composite machine certification

-

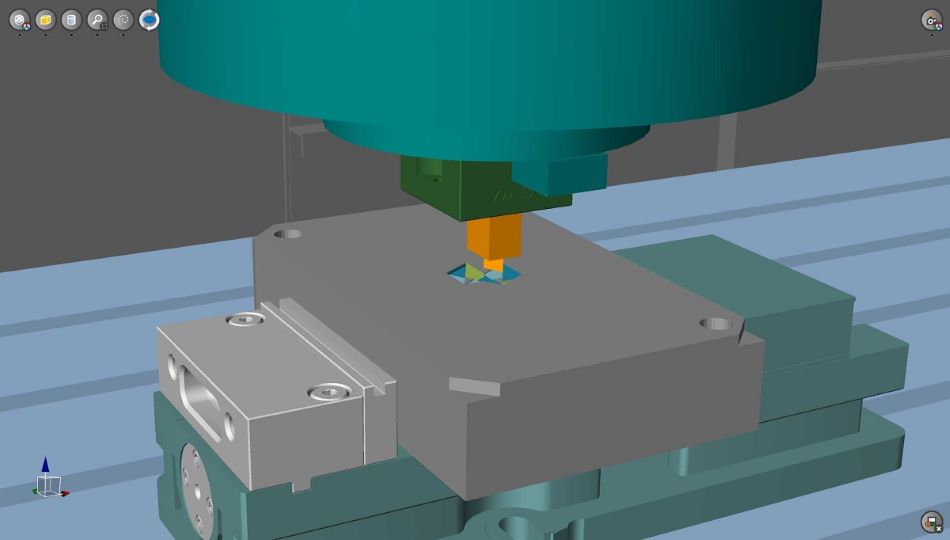

Electrode tool verification

-

User interface improvements

-

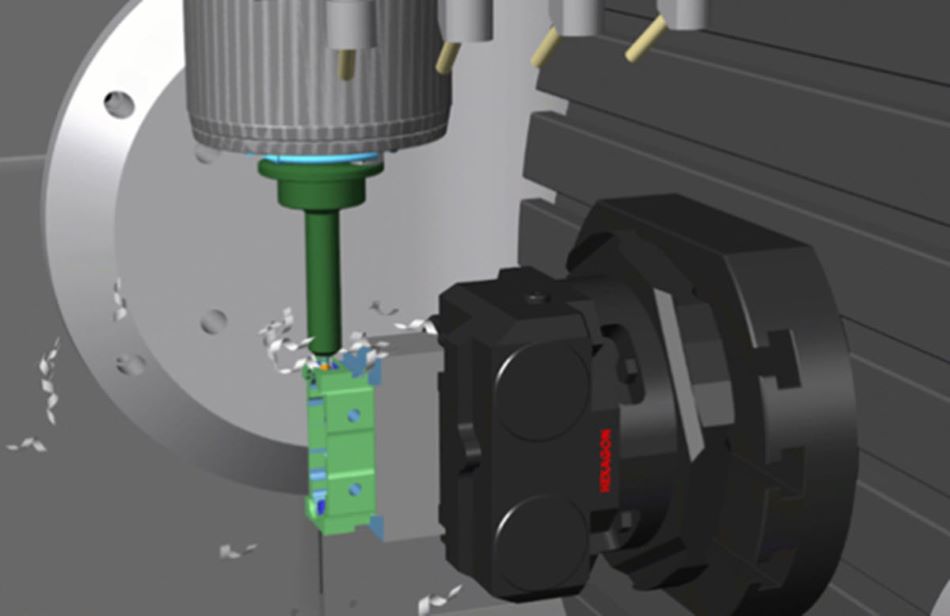

Cutting chips and rotating tools

-

Global CAM interface improvements

-

Heavy CNC program decoding