The digital future of tube manufacturing

An upgrade to the latest TubeInspect P16.2 HRC system and leading BendingStudio XT software offers new opportunities for improving efficiency in tube manufacturing

Contact us

Albert Biebl GmbH is a specialist in the field of tube bending technology. Founded in 1985 in Hauzenberg, Germany, the company’s daily business once included the production of automotive tuning parts. Today, it offers individual solutions in the field of hydraulics to well-known customers from the agricultural and construction machinery, railway, automotive and special machinery industries. The company’s commitment to, and promise of, unconditional quality remains constant to this day.

Biebl’s highly trained employees produce 1.5 million parts annually, using state-of-the-art machines, in 10,000 square metres of hall space. The company’s main applications are lubrication and cooling water pipes, hydraulic pipes and handrails, and they handle pipe diameters of between 3 and 100 millimetres and lengths from 100 millimetres to 5 metres. Beyond production, Biebl offers services including end machining, welding, forming or sawing, and supplies its customers with completely manufactured, ready-to-install piping for assembly.

Biebl’s highly trained employees produce 1.5 million parts annually, using state-of-the-art machines, in 10,000 square metres of hall space. The company’s main applications are lubrication and cooling water pipes, hydraulic pipes and handrails, and they handle pipe diameters of between 3 and 100 millimetres and lengths from 100 millimetres to 5 metres. Beyond production, Biebl offers services including end machining, welding, forming or sawing, and supplies its customers with completely manufactured, ready-to-install piping for assembly.

“The 4th industrial revolution is all about digital, and we are happy and proud to be a part of it,” says Florian Biebl, Managing Director of Albert Biebl GmbH.

In the past, the company performed quality assurance using gauge testing, followed by tactile measurement with a measuring arm. “At that time, this was an incredible advance,” says Biebl. “However, each cylinder had to be touched three-to-four times, and for tubes with 10-20 bends, measurement took a relatively long time.”

In 2012, the company put its first TubeInspect system into operation, bringing immediate quality gains and time savings – especially for long tubes and tubes of smaller diameters, which can present tricky measurement challenges. With TubeInspect, these difficulties are a thing of the past.

In 2012, the company put its first TubeInspect system into operation, bringing immediate quality gains and time savings – especially for long tubes and tubes of smaller diameters, which can present tricky measurement challenges. With TubeInspect, these difficulties are a thing of the past.

“This first machine has operated flawlessly for us,” Biebl says. “But to expand our inspection and measurement capabilities and offer our customers more, we decided to upgrade to the next generation – the TubeInspect P16.2 HRC. Because of the many parts we produce, we’ve kept our dependable first TubeInspect as a backup system to protect us from unforeseen downtime.”

Biebl’s highly trained employees produce 1.5 million parts annually, using state-of-the-art machines, in 10,000 square metres of hall space. The company’s main applications are lubrication and cooling water pipes, hydraulic pipes and handrails, and they handle pipe diameters of between 3 and 100 millimetres and lengths from 100 millimetres to 5 metres. Beyond production, Biebl offers services including end machining, welding, forming or sawing, and supplies its customers with completely manufactured, ready-to-install piping for assembly.

Biebl’s highly trained employees produce 1.5 million parts annually, using state-of-the-art machines, in 10,000 square metres of hall space. The company’s main applications are lubrication and cooling water pipes, hydraulic pipes and handrails, and they handle pipe diameters of between 3 and 100 millimetres and lengths from 100 millimetres to 5 metres. Beyond production, Biebl offers services including end machining, welding, forming or sawing, and supplies its customers with completely manufactured, ready-to-install piping for assembly. “The 4th industrial revolution is all about digital, and we are happy and proud to be a part of it,” says Florian Biebl, Managing Director of Albert Biebl GmbH.

In the past, the company performed quality assurance using gauge testing, followed by tactile measurement with a measuring arm. “At that time, this was an incredible advance,” says Biebl. “However, each cylinder had to be touched three-to-four times, and for tubes with 10-20 bends, measurement took a relatively long time.”

In 2012, the company put its first TubeInspect system into operation, bringing immediate quality gains and time savings – especially for long tubes and tubes of smaller diameters, which can present tricky measurement challenges. With TubeInspect, these difficulties are a thing of the past.

In 2012, the company put its first TubeInspect system into operation, bringing immediate quality gains and time savings – especially for long tubes and tubes of smaller diameters, which can present tricky measurement challenges. With TubeInspect, these difficulties are a thing of the past.“This first machine has operated flawlessly for us,” Biebl says. “But to expand our inspection and measurement capabilities and offer our customers more, we decided to upgrade to the next generation – the TubeInspect P16.2 HRC. Because of the many parts we produce, we’ve kept our dependable first TubeInspect as a backup system to protect us from unforeseen downtime.”

“The time factor, compared to other measuring machines, is the most important advantage - especially with long pipes.”

Florian Biebl

Managing Director

Albert Biebl GmbH

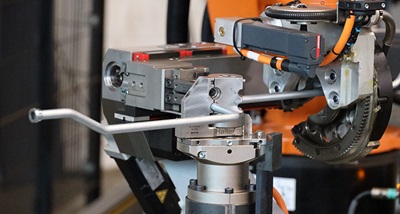

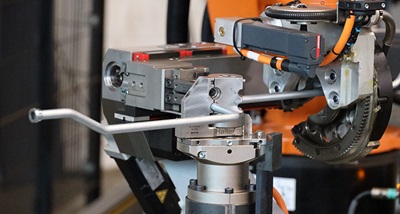

Hexagon’s latest TubeInspect systems, together with the new BendingStudio XT software, form a platform that delivers even faster tube measurement and higher accuracy. The complete solution also brings important new measurement options to the market, particularly in the measurement of square and rectangular cross section tubes, as well as complex geometries, ends and fittings, adaptors, lugs and attachments. “Measuring square tubes has always been a challenge for us. This problem has finally been solved, which makes me very happy,” says Biebl.

Hexagon’s latest TubeInspect systems, together with the new BendingStudio XT software, form a platform that delivers even faster tube measurement and higher accuracy. The complete solution also brings important new measurement options to the market, particularly in the measurement of square and rectangular cross section tubes, as well as complex geometries, ends and fittings, adaptors, lugs and attachments. “Measuring square tubes has always been a challenge for us. This problem has finally been solved, which makes me very happy,” says Biebl. “Measuring square pipes has always been a challenge for us. With TubeInspect and BendingStudio XT, this problem has finally been solved, which makes me very happy.”

Florian Biebl

Managing Director

Albert Biebl GmbH

All these features can now be easily measured at the touch of a button without any additional mechanical aids, which is particularly important for meeting the sampling requirements of Biebl’s customers. Meanwhile, the software’s integrated logging function and improved reporting functionality enable the accurate and easy recording of data for these complex parts, providing customers with the evidence needed to meet ever-increasing sampling and compliance requirements.

All these features can now be easily measured at the touch of a button without any additional mechanical aids, which is particularly important for meeting the sampling requirements of Biebl’s customers. Meanwhile, the software’s integrated logging function and improved reporting functionality enable the accurate and easy recording of data for these complex parts, providing customers with the evidence needed to meet ever-increasing sampling and compliance requirements.The accuracy and speed of the TubeInspect P16.2 in combination with the capabilities and flexibility of BendingStudio XT enable Biebl to offer its customers truly customised solutions and stand out from their competitors.

“It’s great to work with the products of a company that strives to improve. Continuous improvement is the basis of our great collaboration.”

Florian Biebl

Managing Director

Albert Biebl GmbH

Beyond products and software, Biebl values the human and professional cooperation they’ve experienced with Hexagon. “We always find open ears and a willingness to find solutions, for even the most complex parts,” Biebl says. “We know the new system is capable of even more in the future, and Hexagon’s development team is already working on our requests. It’s great to work with a company that strives to improve; continuous improvement is the basis of our great cooperation.”