Process reliability and productivity

Contact us

Probes with infrared data transmission, laser tool measuring systems and measurement software, all from m&h, ensure Kinzingen-based Rothe’s process reliability and that machining centre output is accurate. The result is a clear increase in productivity and considerably less reworking.

Rothe, based in Franconian Kitzingen specialises in carrier tape for a wide variety of industries. Even at first glance, it is clear that the company’s manufacturing is a specialist operation.

Rothe, based in Franconian Kitzingen specialises in carrier tape for a wide variety of industries. Even at first glance, it is clear that the company’s manufacturing is a specialist operation.

Founded in 1963, Rothe was one of the pioneers of carrier tape, which is manufactures by around 140 employees in a three-shift operation. The self-built moulding machines, in which the moulds are placed in carrier tape, may seem unassuming, but they are based on years of experience and sophisticated expertise.

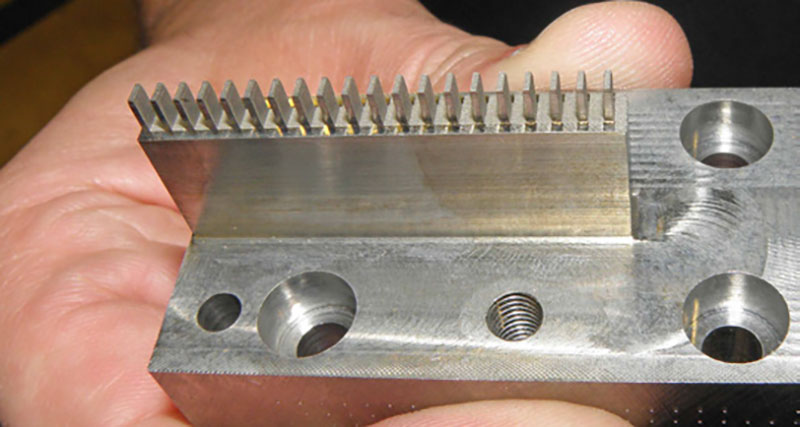

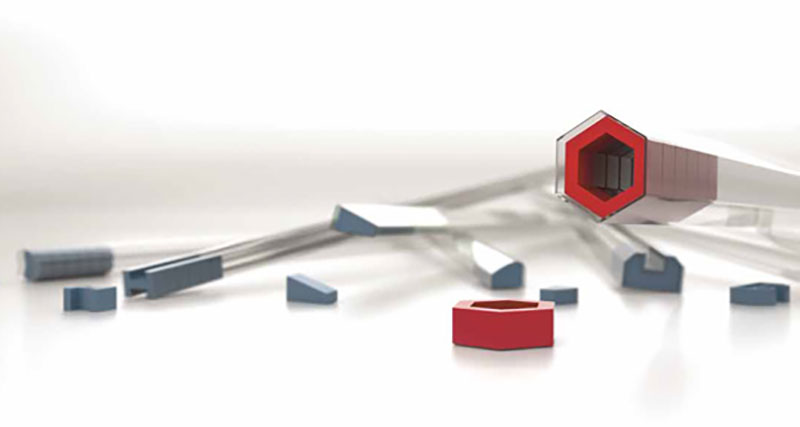

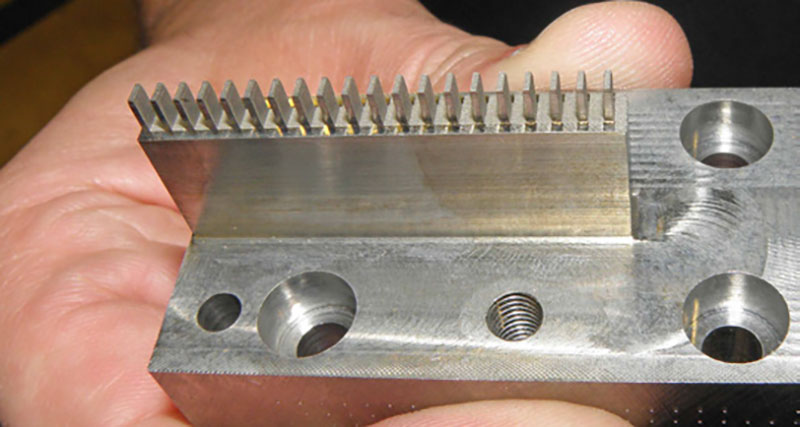

Carrier tapes are plastic tapes, which use cup-shaped recesses to house components and feed them into automatic assembly machines. These tapes can vary from 8 mm to 104 mm in thickness, and the shape and depth are individually adapted to each assembly item to be carried. Accuracy in the hundredths is therefore required, as assembly items must not fall out or slip; they should be supplied correctly and precisely according to the handover position for assembly.

The tapes are made using a type of deep drawing, where the plastic carrier tape is first preheated in order to pass the moulding tool to where the tape is formed. Depending on customer specifications, small holes can be made in the recesses to enable the cavity to be aerated and ventilated. These holes can be extremely small, which is why Rothe sometimes uses special laser machines for this. In many cases, a hole sequence is introduced at the same time, which ensures secure positioning and transport within assembly machines. Finally, the carrier tape is cut to the desired thickness and wound onto large drums.

The tapes are made using a type of deep drawing, where the plastic carrier tape is first preheated in order to pass the moulding tool to where the tape is formed. Depending on customer specifications, small holes can be made in the recesses to enable the cavity to be aerated and ventilated. These holes can be extremely small, which is why Rothe sometimes uses special laser machines for this. In many cases, a hole sequence is introduced at the same time, which ensures secure positioning and transport within assembly machines. Finally, the carrier tape is cut to the desired thickness and wound onto large drums.

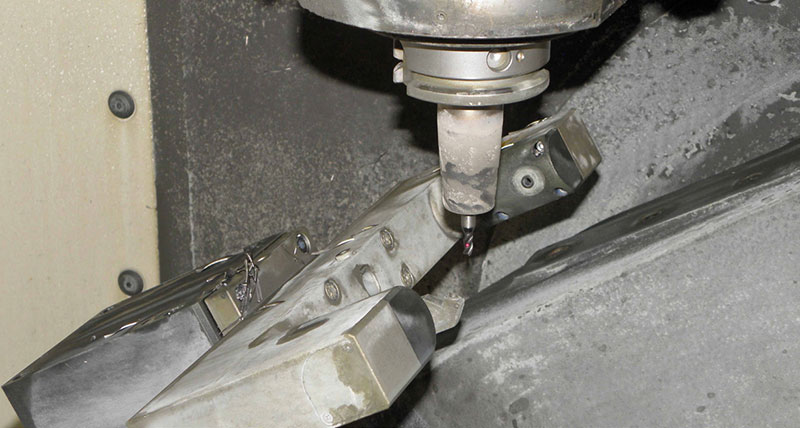

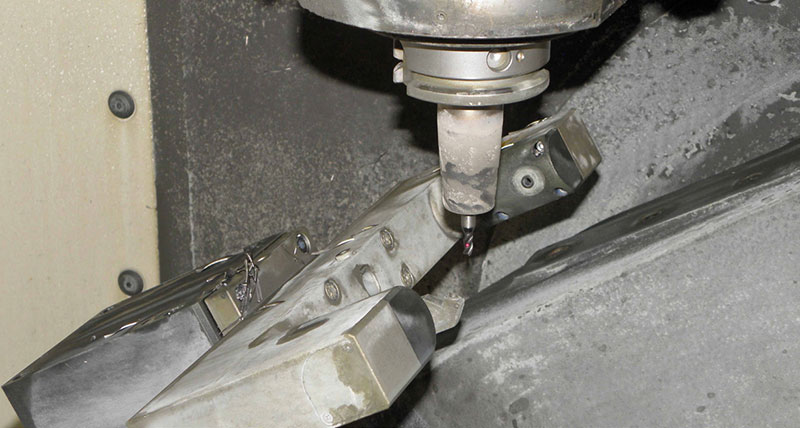

As fast-running machines with short cycle times and long running times are used for both carrier tape and single blisters, the moulds must be similarly exact and durable. Last but not least, the moulds are all manufactured in-house at Rothe.

This not only ensures company expertise, it also enables flexible, short reaction times in the event of repairs being required. An important factor for a company that works over three shifts every day. “We are now able to repair mould defects within one working day”, exclaims Bernd Gruber, Head of Tool Manufacture at Rothe. The Mikron HEM 500U machining centre is equipped with an m&h probe with infrared transmission technology. The m&h IRP25.41 probe has a stainless steel casing and a toughened glass cover of high-performance infrared diodes. It takes a standard 9-volt battery, which can be changed in a few simple steps and without any special tools. Like all m&h devices, this probe is sealed to IP68 standard and ideally equipped for the adverse conditions in the machining area of machine tools. The HDR transmission technology developed by m&h, which enables entire data packages to be sent in the place of mere signals, ensures that only signals for the probe are processed, which ensures a high degree of process reliability and eliminates faulty switching or unplanned machine downtime due to potential interference signals.

This not only ensures company expertise, it also enables flexible, short reaction times in the event of repairs being required. An important factor for a company that works over three shifts every day. “We are now able to repair mould defects within one working day”, exclaims Bernd Gruber, Head of Tool Manufacture at Rothe. The Mikron HEM 500U machining centre is equipped with an m&h probe with infrared transmission technology. The m&h IRP25.41 probe has a stainless steel casing and a toughened glass cover of high-performance infrared diodes. It takes a standard 9-volt battery, which can be changed in a few simple steps and without any special tools. Like all m&h devices, this probe is sealed to IP68 standard and ideally equipped for the adverse conditions in the machining area of machine tools. The HDR transmission technology developed by m&h, which enables entire data packages to be sent in the place of mere signals, ensures that only signals for the probe are processed, which ensures a high degree of process reliability and eliminates faulty switching or unplanned machine downtime due to potential interference signals.

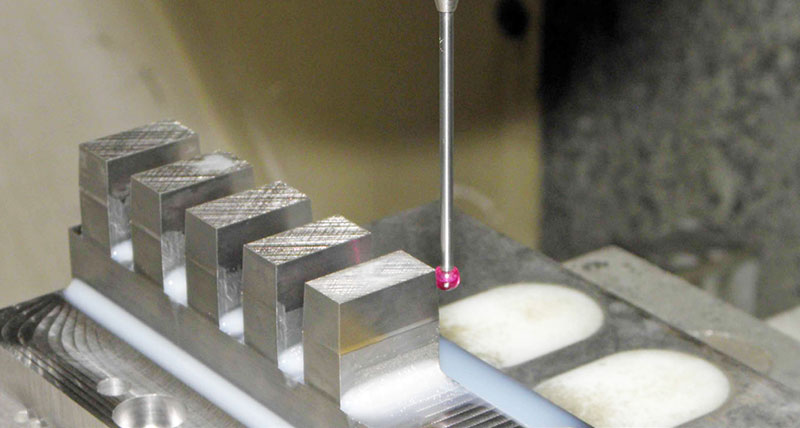

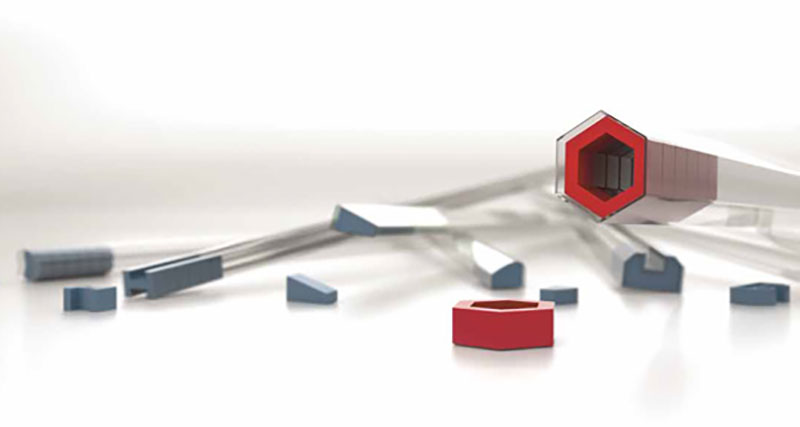

The process reliability of m&h devices is also clear to see in the seamless application of its LTS35.65-160 laser tool setter, which is also installed on this machine. This is how the length and diameter of tools are measured when they are tensed in the machine and when the spindle is rotated. As many small tools with diameters from 0.6 mm are used at Rothe, the contactless measurement has proved its worth. “Compared to the competitor model on the previous machine, the m&h laser tool setter works much better in certain aspects”, explains Bernd Gruber of his experience. “The air jet simply blasts away any dirt on edges. The laser optics lenses no longer need to be cleaned. The maintenance costs are also a lot lower. It’s just a great fit.”

We have a much higher success rate when it comes to initial moulds and much less reworking.The laser is mounted directly on the tilting table of the five-axis machine and the permanent coolant flow and chips are exposed. But this does not affect the m&h tool setter. The device’s sealing technology provides reliable protection for the interior optics, even if the airflow stops or the machine is switched off. If the measuring process is terminated, the small laser optics chamber is sealed and filled with pressure via compressed air. This eliminates any contamination due to dirt particles. If dirt deposits build up on the external opening of the light channel, it is blown away when the lens is next opened by the sudden escape of pressure from the optical chamber. In addition, an air curtain can be used for measuring, which prevents contamination during the measuring process. Potential dirt adhering to edges is reliably removed by blowing it away with a specially designed compressed air nozzle. This nozzle directs and accelerates the air stream so powerfully that supersonic speed is reached in the centre of the air stream. The nozzle therefore develops extremely strong cleaning power. It is therefore no surprise that the existing tool presetting device at Rothe has not been used for some time.

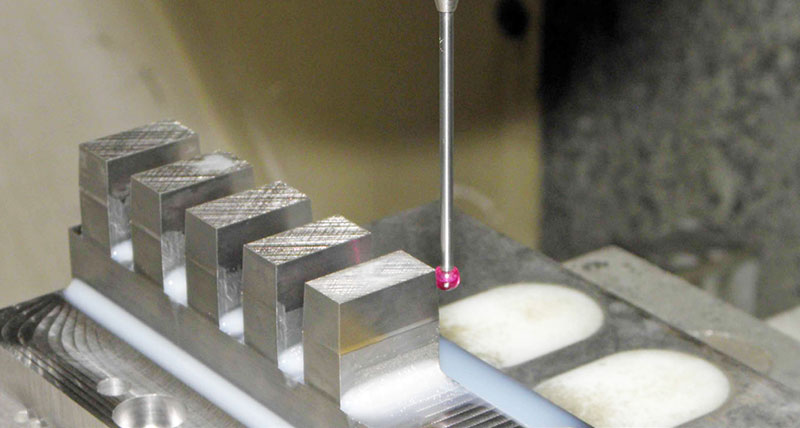

Besides the m&h hardware, Rothe also began using 3D Form Inspect software two years ago for direct control and to compare the tool’s targets with its performance in the machine from the CAD data in the drawing. The tools must therefore no longer be removed from the machine to check them on a measurement machine and then replace them, which always equates to a loss of quality and considerable time spent. “We do far fewer repeats and have noticeably less reworking to do”, reports Bernd Gruber. “Now, everything is clearly documented nd, if anything is incorrect, we know straight away which parameters are responsible and can then immediately react and reset them.” The straightforward software is well liked by all employees, yet it still results in reduced workload and prevents errors and inaccurate measurements. m&h 3D Form Inspect software displays a surface model of the tool, on which the user clicks the points to be measured. A further click will assign the desired measurement function to the points. In many cases, the software defines the required counterpoints automatically, preventing inaccuracies and measuring errors. Before the automatically generated measuring programme is transferred to the machine, there is a collision check using the contours of the tool, which ensures maximum process reliability. Now it’s also possible to measure things that were previously impossible or would have required a lot of time. This allows the smallest of contours or mould inclines to be measured, which was virtually impossible to do manually previously. “Employees like working with it because all measurements are documented and less contestable. We have considerably increased our success rate”, exclaims Bernd Gruber. “We have a much higher success rate when it comes to initial moulds and much less reworking. The measuring results are clear confirmation of our work and offer a reassuring guarantee of quality.”

Besides the m&h hardware, Rothe also began using 3D Form Inspect software two years ago for direct control and to compare the tool’s targets with its performance in the machine from the CAD data in the drawing. The tools must therefore no longer be removed from the machine to check them on a measurement machine and then replace them, which always equates to a loss of quality and considerable time spent. “We do far fewer repeats and have noticeably less reworking to do”, reports Bernd Gruber. “Now, everything is clearly documented nd, if anything is incorrect, we know straight away which parameters are responsible and can then immediately react and reset them.” The straightforward software is well liked by all employees, yet it still results in reduced workload and prevents errors and inaccurate measurements. m&h 3D Form Inspect software displays a surface model of the tool, on which the user clicks the points to be measured. A further click will assign the desired measurement function to the points. In many cases, the software defines the required counterpoints automatically, preventing inaccuracies and measuring errors. Before the automatically generated measuring programme is transferred to the machine, there is a collision check using the contours of the tool, which ensures maximum process reliability. Now it’s also possible to measure things that were previously impossible or would have required a lot of time. This allows the smallest of contours or mould inclines to be measured, which was virtually impossible to do manually previously. “Employees like working with it because all measurements are documented and less contestable. We have considerably increased our success rate”, exclaims Bernd Gruber. “We have a much higher success rate when it comes to initial moulds and much less reworking. The measuring results are clear confirmation of our work and offer a reassuring guarantee of quality.”

In the meantime, not only is every tool that is produced on the machining centre checked at Rothe, but also critical parts that are produced in electrical discharge machines. “Deviations in accuracy often used to be a matter of one person’s word against another’s. Now, everything is clearly documented and without a great deal of effort. In terms of total measurement time, the low time requirement for measurement is negligible”, emphasises Bernd Gruber. “So we know for sure that everything is in accordance with the drawing”.

The fast reaction times of the m&h replacement parts service are also well regarded. “Styli and replacement parts are available at reasonable prices and they are delivered within one working day of a fault”, adds Bernd Gruber.

Rothe, based in Franconian Kitzingen specialises in carrier tape for a wide variety of industries. Even at first glance, it is clear that the company’s manufacturing is a specialist operation.

Rothe, based in Franconian Kitzingen specialises in carrier tape for a wide variety of industries. Even at first glance, it is clear that the company’s manufacturing is a specialist operation.Founded in 1963, Rothe was one of the pioneers of carrier tape, which is manufactures by around 140 employees in a three-shift operation. The self-built moulding machines, in which the moulds are placed in carrier tape, may seem unassuming, but they are based on years of experience and sophisticated expertise.

Carrier tapes are plastic tapes, which use cup-shaped recesses to house components and feed them into automatic assembly machines. These tapes can vary from 8 mm to 104 mm in thickness, and the shape and depth are individually adapted to each assembly item to be carried. Accuracy in the hundredths is therefore required, as assembly items must not fall out or slip; they should be supplied correctly and precisely according to the handover position for assembly.

The tapes are made using a type of deep drawing, where the plastic carrier tape is first preheated in order to pass the moulding tool to where the tape is formed. Depending on customer specifications, small holes can be made in the recesses to enable the cavity to be aerated and ventilated. These holes can be extremely small, which is why Rothe sometimes uses special laser machines for this. In many cases, a hole sequence is introduced at the same time, which ensures secure positioning and transport within assembly machines. Finally, the carrier tape is cut to the desired thickness and wound onto large drums.

The tapes are made using a type of deep drawing, where the plastic carrier tape is first preheated in order to pass the moulding tool to where the tape is formed. Depending on customer specifications, small holes can be made in the recesses to enable the cavity to be aerated and ventilated. These holes can be extremely small, which is why Rothe sometimes uses special laser machines for this. In many cases, a hole sequence is introduced at the same time, which ensures secure positioning and transport within assembly machines. Finally, the carrier tape is cut to the desired thickness and wound onto large drums.As fast-running machines with short cycle times and long running times are used for both carrier tape and single blisters, the moulds must be similarly exact and durable. Last but not least, the moulds are all manufactured in-house at Rothe.

This not only ensures company expertise, it also enables flexible, short reaction times in the event of repairs being required. An important factor for a company that works over three shifts every day. “We are now able to repair mould defects within one working day”, exclaims Bernd Gruber, Head of Tool Manufacture at Rothe. The Mikron HEM 500U machining centre is equipped with an m&h probe with infrared transmission technology. The m&h IRP25.41 probe has a stainless steel casing and a toughened glass cover of high-performance infrared diodes. It takes a standard 9-volt battery, which can be changed in a few simple steps and without any special tools. Like all m&h devices, this probe is sealed to IP68 standard and ideally equipped for the adverse conditions in the machining area of machine tools. The HDR transmission technology developed by m&h, which enables entire data packages to be sent in the place of mere signals, ensures that only signals for the probe are processed, which ensures a high degree of process reliability and eliminates faulty switching or unplanned machine downtime due to potential interference signals.

This not only ensures company expertise, it also enables flexible, short reaction times in the event of repairs being required. An important factor for a company that works over three shifts every day. “We are now able to repair mould defects within one working day”, exclaims Bernd Gruber, Head of Tool Manufacture at Rothe. The Mikron HEM 500U machining centre is equipped with an m&h probe with infrared transmission technology. The m&h IRP25.41 probe has a stainless steel casing and a toughened glass cover of high-performance infrared diodes. It takes a standard 9-volt battery, which can be changed in a few simple steps and without any special tools. Like all m&h devices, this probe is sealed to IP68 standard and ideally equipped for the adverse conditions in the machining area of machine tools. The HDR transmission technology developed by m&h, which enables entire data packages to be sent in the place of mere signals, ensures that only signals for the probe are processed, which ensures a high degree of process reliability and eliminates faulty switching or unplanned machine downtime due to potential interference signals.The process reliability of m&h devices is also clear to see in the seamless application of its LTS35.65-160 laser tool setter, which is also installed on this machine. This is how the length and diameter of tools are measured when they are tensed in the machine and when the spindle is rotated. As many small tools with diameters from 0.6 mm are used at Rothe, the contactless measurement has proved its worth. “Compared to the competitor model on the previous machine, the m&h laser tool setter works much better in certain aspects”, explains Bernd Gruber of his experience. “The air jet simply blasts away any dirt on edges. The laser optics lenses no longer need to be cleaned. The maintenance costs are also a lot lower. It’s just a great fit.”

We have a much higher success rate when it comes to initial moulds and much less reworking.The laser is mounted directly on the tilting table of the five-axis machine and the permanent coolant flow and chips are exposed. But this does not affect the m&h tool setter. The device’s sealing technology provides reliable protection for the interior optics, even if the airflow stops or the machine is switched off. If the measuring process is terminated, the small laser optics chamber is sealed and filled with pressure via compressed air. This eliminates any contamination due to dirt particles. If dirt deposits build up on the external opening of the light channel, it is blown away when the lens is next opened by the sudden escape of pressure from the optical chamber. In addition, an air curtain can be used for measuring, which prevents contamination during the measuring process. Potential dirt adhering to edges is reliably removed by blowing it away with a specially designed compressed air nozzle. This nozzle directs and accelerates the air stream so powerfully that supersonic speed is reached in the centre of the air stream. The nozzle therefore develops extremely strong cleaning power. It is therefore no surprise that the existing tool presetting device at Rothe has not been used for some time.

Besides the m&h hardware, Rothe also began using 3D Form Inspect software two years ago for direct control and to compare the tool’s targets with its performance in the machine from the CAD data in the drawing. The tools must therefore no longer be removed from the machine to check them on a measurement machine and then replace them, which always equates to a loss of quality and considerable time spent. “We do far fewer repeats and have noticeably less reworking to do”, reports Bernd Gruber. “Now, everything is clearly documented nd, if anything is incorrect, we know straight away which parameters are responsible and can then immediately react and reset them.” The straightforward software is well liked by all employees, yet it still results in reduced workload and prevents errors and inaccurate measurements. m&h 3D Form Inspect software displays a surface model of the tool, on which the user clicks the points to be measured. A further click will assign the desired measurement function to the points. In many cases, the software defines the required counterpoints automatically, preventing inaccuracies and measuring errors. Before the automatically generated measuring programme is transferred to the machine, there is a collision check using the contours of the tool, which ensures maximum process reliability. Now it’s also possible to measure things that were previously impossible or would have required a lot of time. This allows the smallest of contours or mould inclines to be measured, which was virtually impossible to do manually previously. “Employees like working with it because all measurements are documented and less contestable. We have considerably increased our success rate”, exclaims Bernd Gruber. “We have a much higher success rate when it comes to initial moulds and much less reworking. The measuring results are clear confirmation of our work and offer a reassuring guarantee of quality.”

Besides the m&h hardware, Rothe also began using 3D Form Inspect software two years ago for direct control and to compare the tool’s targets with its performance in the machine from the CAD data in the drawing. The tools must therefore no longer be removed from the machine to check them on a measurement machine and then replace them, which always equates to a loss of quality and considerable time spent. “We do far fewer repeats and have noticeably less reworking to do”, reports Bernd Gruber. “Now, everything is clearly documented nd, if anything is incorrect, we know straight away which parameters are responsible and can then immediately react and reset them.” The straightforward software is well liked by all employees, yet it still results in reduced workload and prevents errors and inaccurate measurements. m&h 3D Form Inspect software displays a surface model of the tool, on which the user clicks the points to be measured. A further click will assign the desired measurement function to the points. In many cases, the software defines the required counterpoints automatically, preventing inaccuracies and measuring errors. Before the automatically generated measuring programme is transferred to the machine, there is a collision check using the contours of the tool, which ensures maximum process reliability. Now it’s also possible to measure things that were previously impossible or would have required a lot of time. This allows the smallest of contours or mould inclines to be measured, which was virtually impossible to do manually previously. “Employees like working with it because all measurements are documented and less contestable. We have considerably increased our success rate”, exclaims Bernd Gruber. “We have a much higher success rate when it comes to initial moulds and much less reworking. The measuring results are clear confirmation of our work and offer a reassuring guarantee of quality.”

In the meantime, not only is every tool that is produced on the machining centre checked at Rothe, but also critical parts that are produced in electrical discharge machines. “Deviations in accuracy often used to be a matter of one person’s word against another’s. Now, everything is clearly documented and without a great deal of effort. In terms of total measurement time, the low time requirement for measurement is negligible”, emphasises Bernd Gruber. “So we know for sure that everything is in accordance with the drawing”.

The fast reaction times of the m&h replacement parts service are also well regarded. “Styli and replacement parts are available at reasonable prices and they are delivered within one working day of a fault”, adds Bernd Gruber.