Portable measuring arm ensures the performance of photovoltaic modules

AT&S - Austria

Contact us

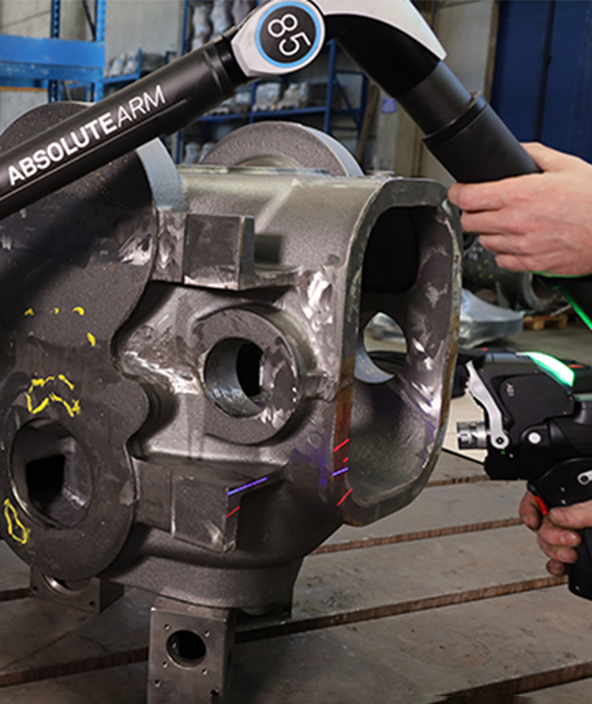

Europe‘s number 1 circuit board manufacturer, Austrian company AT&S, has developed a new type of solar module with a particularly high efficiency rating. Hexagon’s portable measuring arm is helping to make the most of the performance capabilities of the modules.

AT&S is one of the world’s leading suppliers of highquality circuit boards. These boards carry and provide the electrical connection to mounted components in practically every electronic device. AT&S products are mainly used in portable devices such as smartphones and tablet PCs, in automobiles and the fields of industrial and biomedical technology up to 2% per module. “The cumulative loss for a large installation over decades is immense.”

The solder ribbon dilemma

AT&S exploits the know-how gained from making circuit boards to manufacture photovoltaic modules using a new connection technology. Solar systems consist of individual cells connected together to form a solar module. In conventional modules, the cells are connected by solder ribbons to conduct the current. The manufacturers of these modules either use relatively thick ribbons (which leads to greater shadowing of the active cell surface) or very thin ribbons (which cannot carry as much current). In either case, these solar modules are less efficient because the calculation is based on the sum of the theoretical output of each cell. Mario Egger, Photovoltaics Department Manager at AT&S, says: “The use of these connecting ribbons results in efficiency losses of up to 2% per module. The cumulative loss for a large installation over decades is immense.”

Backsheet foils mean more output

AT&S has completely avoided the connecting ribbon dilemma in its photovoltaic products. At its factory in Leoben, the company manufactures conducting foils for providing the contact on the back of the solar modules. Various coatings on the conducting surface insulate and strengthen the foil. Thirty-one contacts, which must coincide with precisely defined points on the back of the solar cells, are left uncoated on each foil.

"The backsheet foil minimises the efficiency loss of the solar module – which is a factor of 10 less than with soldering bands."