m&h touch probe with Chamäleon technology - always adaptable

Wilhelm Kissendorfer OHG - Germany

Contact us

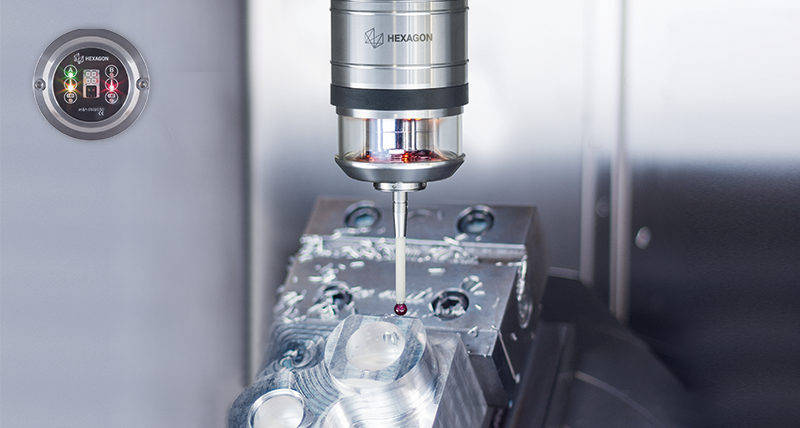

Because older touch probe models from some providers are no longer available or would be expensive and time-consuming to repair, Kissendorfer is converting to m&h touch probes. Their m&h IRP25.41 Chamäleon model can be adapted to the receiver systems of other manufacturers in existing machines. The ideal replacement, even when a fast remedy is required following a crash.

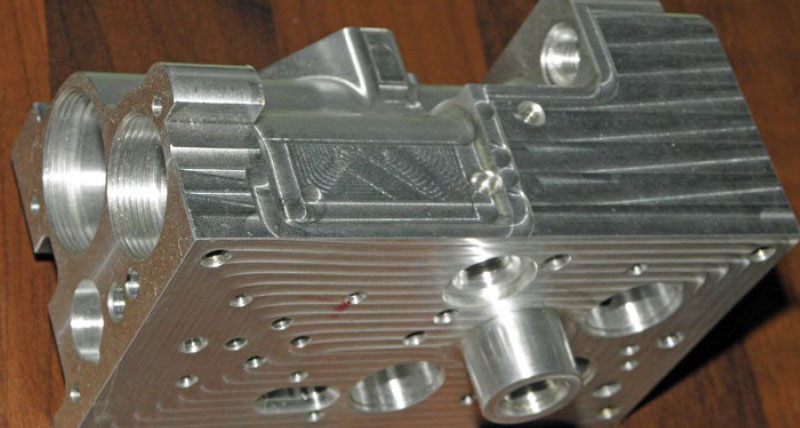

High quality components and short production runs with high precision are what the Kissendorfer company in Munich does best. Approximately 40 employees manufacture precision parts, pre-assembled components through to complete special machines according to drawing. Repeat parts are quite rare.

“We are more concerned with hundredths here”, explains Robert Fesenmair, Plant Manager at the company. Since 1931, Kissendorfer has developed a broad base of loyal clients, which on the one hand makes the company crisis-proof thanks to the wide range of customer industries, but on the other hand poses constantly changing challenges.

Adaptability and versatility are the preconditions for always being able to meet the new demands of customers. The machining facilities at Kissendorfer are equally versatile. Various machining centres, some 3-axis, some 5-axis, as well as a jig borer can machine workpieces up to 2 m. Various lathes, lathe-milling centres, face grinders, cylindrical grinders, a coordinate grinder, as well as spark-erosion machines provide the full range of machining processes. Kissendorfer also has several assembly areas for the assembly of equipment and special machines. Of course, all possible materials are also machined here, most of which are manufactured from different steels, aluminium alloys and castings. This variety permits not only any type of component machining according to customer drawing, but is also the basis for the precision that is so valued by many regular Kissendorfer customers from a wide range of industries, starting with the automobile industry, aviation and astronautics, pharmaceuticals, packaging and mechanical engineering.

Adaptability and versatility are the preconditions for always being able to meet the new demands of customers. The machining facilities at Kissendorfer are equally versatile. Various machining centres, some 3-axis, some 5-axis, as well as a jig borer can machine workpieces up to 2 m. Various lathes, lathe-milling centres, face grinders, cylindrical grinders, a coordinate grinder, as well as spark-erosion machines provide the full range of machining processes. Kissendorfer also has several assembly areas for the assembly of equipment and special machines. Of course, all possible materials are also machined here, most of which are manufactured from different steels, aluminium alloys and castings. This variety permits not only any type of component machining according to customer drawing, but is also the basis for the precision that is so valued by many regular Kissendorfer customers from a wide range of industries, starting with the automobile industry, aviation and astronautics, pharmaceuticals, packaging and mechanical engineering.

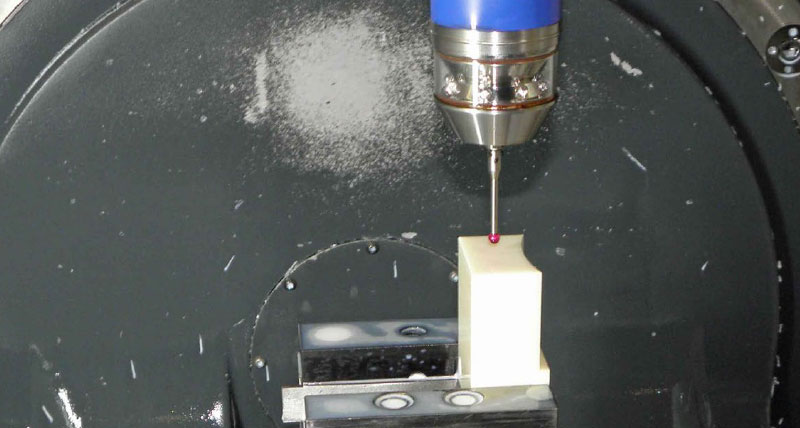

“One can hardly compete these days with pure metal cutting”, explains Robert Fesenmair. “We always try to unload and reset the machined parts as little as possible, because resetting the parts does not make them more accurate. Our customers rely on our precision. That’s why they keep coming back to us.” Not least because the machining centres at Kissendorfer, whether they are from DMG, Hermle or Grob, are all equipped with touch probes. They contribute to efficiency and precision, especially during setup. When parts are probed at Kissendorfer, after a quick adjustment the position of the workpiece is determined exactly and the machining program is aligned to the actual position of the workpiece. During and after machining, critical dimensions are checked using the measuring cycles of the relevant control. In this way, users can quickly make sure that the positions of bore fits match and that the workpieces are holding their tolerances.

Depending on the make and age of the touch probes, maintenance or repair work may occasionally be necessary. With some touch probe brands, Kissendorfer encountered the problem that older touch probes were no longer available from the manufacturers, or that spare parts could no longer be supplied. Good advice was needed, but that would also be time-consuming. In the meantime, the m&h touch probes were being used on the new machining centres from DMG, Hermle and Grob. They proved to be particularly user friendly and robust.

As a replacement for touch probes from third party brands, the m&h IRP25.41 can offer its so-called Chamäleon devices, which are able to communicate with the existing receiver systems of other manufacturers. Because these can usually even be supplied from stock, Kissendorfer has decided to make the switch and in such cases to replace the old devices of other manufacturers with m&h touch probes. These Chamäleon touch probes can be set via a multi-switch to the different communication standards for infrared data transfer and can therefore send their signals to the systems of other manufacturers. The existing receiver systems can thus still be used on the machines without any expensive and time-consuming retrofitting. The usual measuring programs and cycles also remain the same.

Our customers rely on our precision. That’s why they keep coming back to us

The touch probes are switched on and off using the normal m&h method, by mechanical switching when they are inserted in the work spindle. The m&h IRP25.41 is usually equipped with microswitches in the tie bolt of the steep taper or on the flange of the HSK versions. Alternative ON/OFF switching methods are available on request. This guarantees absolutely reliable functioning of the touch probes, which prevents unplanned machine stops. Because the m&h IRP25.41 is safely switched off in the magazine, energy consumption is reduced significantly compared with other models, which means a very long battery life.

All m&h touch probes are also operated using standard commercially available batteries that can be replaced quickly and easily without special tools. Kissendorfer users praise this characteristic of the m&h touch probes, because the process is fast and the tightness of the battery compartment is always guaranteed.

The different workpieces and changing requirements also mean that the Kissendorfer manufacturing processes have to be constantly adjusted and changed. Sometimes there are collisions and unplanned downtime. “Unfortunately, collisions usually happen with an expensive touch probe and not with a cheap tool”, says Robert Fesenmair with disappointing experience. “But even then the m&h touch probes are a great help, because we can quickly go from one machine to the other. We just have to change the switch to the other system. And off we go again. In this way we are always adaptable and flexible.” But on-site replacement is also fast. “If we have to carry out a repair, a replacement device is usually sent within one working day. The process works really well”, as Robert Fesenmair praises his suppliers. “We no longer lose valuable time in these situations.”

After only a few m&h touch probes, which were originally supplied with new machines, Kissendorfer has since switched more and more to the adaptable Chamäleon touch probes. In the meantime, 7 m&h IRP25.41 have already become essential tools for daily operations at Kissendorfer.