3D scan data for any object size and shape

Contact us

From designer sockets to small-sized plastic parts all the way up to car body panels or individually designed vehicle shapes: the application areas for reverse engineering present an exciting and versatile field for precise three-dimensional digitisation.

It only takes a short, yet precise measuring process from the actual object to generate its precise three-dimensional model: no matter whether the objects in question are handcrafted prototypes or samples, or whether they are older product models without respective CAD data, the data acquisition of even the most complex free form areas is completed within a matter of seconds. Upon completion of the acquisition, the generated 3D data is imported into the reverse engineering software and converted into a CAD model. The CAD data generated through this process is then used for serial production, as basis for mold and tooling production or for comparison analysis.

3D digitisation enables new serial production

3D digitisation enables new serial production

To resume the serial production of the component in this case, a new die casting mold has to be created. As the component is older and its CAD data therefore do not yet exist, both a 3D digitisation followed by reverse engineering of the component are required. The reverse engineering process is described and illustrated in detail using the example of a plastic frame.

Featuring shaded areas, undercuts and numerous edges, the component presents a rather complex geometry which for conventional digitisation devices poses a particular challenge with regard to the data acquisition. In light of the demanding requirements with regard to resolution, accuracy and completeness of the data, the AICON SmartScan has been chosen for the task.

The flexible and easily adjustable sensor configuration of the AICON SmartScan series allows the object to be scanned at triangulation angles of 30°, 20° and 10°, thus allowing even very difficult accessible areas to be captured at high level of detail and accuracy.

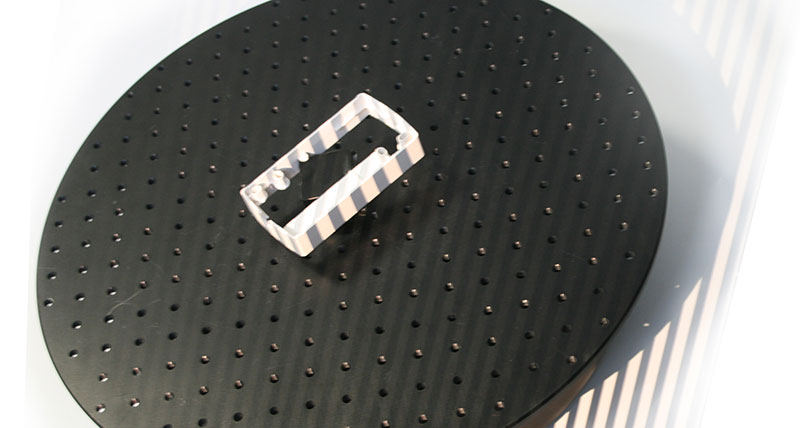

For a mostly automated digitisation process, the scanner is additionally equipped with an optionally available automatic turn table unit.

The project entails two main phases: In a first step, the plastic frame is captured three-dimensionally with the help of the SmartScan. In the second step, a surface model is generated with the use of the reverse engineering software Rapidform XOR2. This three-dimensional surface model (CAD data set) is delivered as final product.

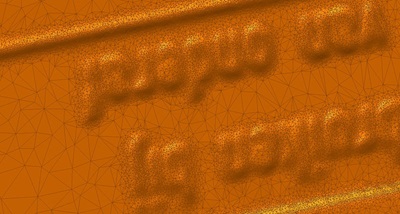

The data acquisition of the component is carried out with the help of a turn table, allowing for a predominantly automatic digitisation of the measuring object. The few individual areas which have been missed in this phase are subsequently filled in with additional captures. Upon the complete data capturing of the object, a 3D dataset (polygon mesh) is evaluated which is then passed to the reverse engineering software Rapidform XOR 2. The 3D model is taken from the scan process; the reverse engineering process is carried out, generating a complete CAD data set. For verification of the reverse engineering result, the 3D model (polygon mesh) and the reversed data set (CAD model) are compared within a split second. Any deviations between the two models are visualized through false color representation. For the purpose of serial inspection, these comparison procedures can be automated.

The data acquisition of the component is carried out with the help of a turn table, allowing for a predominantly automatic digitisation of the measuring object. The few individual areas which have been missed in this phase are subsequently filled in with additional captures. Upon the complete data capturing of the object, a 3D dataset (polygon mesh) is evaluated which is then passed to the reverse engineering software Rapidform XOR 2. The 3D model is taken from the scan process; the reverse engineering process is carried out, generating a complete CAD data set. For verification of the reverse engineering result, the 3D model (polygon mesh) and the reversed data set (CAD model) are compared within a split second. Any deviations between the two models are visualized through false color representation. For the purpose of serial inspection, these comparison procedures can be automated.

Last steps of the reverse engineering process are the documentation of the deviations, conversion of the final CAD data set and delivery to the customer using this data for the mold and tooling production.

Efficient processes and high-quality products

Efficient processes and high-quality products

Thanks to the highly accurate digitisation, existing and new designs are captured precisely as three-dimensional representations and prepared to use for the tool making and subsequent production processes. In spite of processing vast data volumes, an efficient workflow is ensured through automation of the digitisation process.

The AICON SmartScan allows for the simple and swift interpretation of the measuring results. The user is provided with a more comprehensive data base for further processing, ensuring that reverse engineering not only provides a highly efficient tool within the production process, but also delivers prime quality plastic frames as final result.